Insulating ethylene propylene rubber LSOH electric power or control cable for ships and warships and processing method thereof

An ethylene-propylene rubber insulation and control cable technology, applied in the direction of insulated cables, rubber insulators, insulated conductors, etc., can solve the problems of lack of plant and equipment, no detailed product specifications, difficult to control concentricity, etc., and achieve excellent flue gas index. , The effect of eliminating vulcanization equipment and excellent softness characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

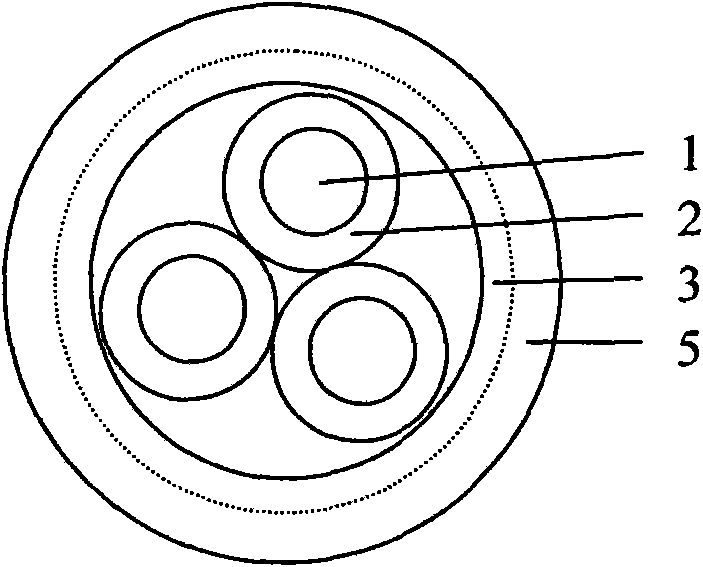

[0011] Control attached figure 1 , its structure is that each conductor 1 is stranded with tinned copper wires, and the outer layer of each conductor 1 is provided with an extruded ethylene-propylene rubber insulation layer 2; multiple insulated wire cores are twisted together; three insulation layers 2 and the sheath layer 5 is the armor layer 3, and the outer layer of the armor layer 3 is the sheath layer 5.

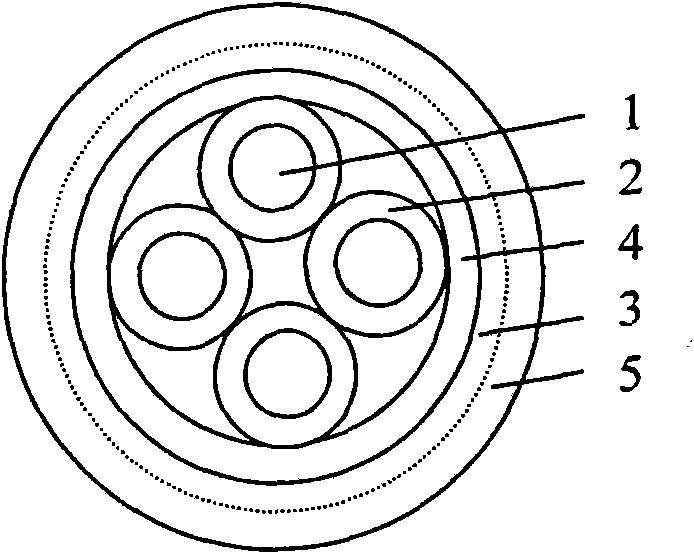

[0012] Control attached figure 2 , its structure is that each conductor 1 is twisted with multiple tinned copper wires, and the outer layer of each core conductor 1 is provided with an extruded ethylene-propylene rubber insulating layer 2; multiple insulated cores are twisted together; four insulated Between the layer 2 and the armor layer 3 is the inner sheath layer 4 , between the inner sheath layer 4 and the sheath layer 5 is the armor layer 3 , and the outer layer of the armor layer 3 is the sheath layer 5 .

[0013] Low-smoke cables for ships and ethylene-propy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com