Halogen-free intumescent compound flame retardant and application thereof in high-density polyethylene

A technology of high-density polyethylene and compound flame retardant, which is applied in the field of flame retardants, can solve the problems of fast burning speed and large fire hazards, and achieves high flame retardant efficiency, control of molten drop phenomenon, and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

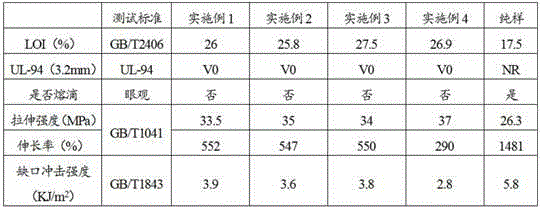

Examples

Embodiment 1

[0020] (1) In terms of mass percentage, the formulation of the halogen-free intumescent compound flame retardant prepared in this example is as follows: 60% ammonium polyphosphate, 18% DPER, 5% triazine char former, 7% melamine cyanurate , 10% hypophosphite; after weighing the corresponding raw materials according to the above formula, add them into the high mixer and mix them evenly to obtain the halogen-free intumescent compound flame retardant of the present embodiment;

[0021] (2) In terms of mass percentage, the raw material formula for preparing the flame-retardant high-density polyethylene material in this example includes the following components: 58.5% HDPE resin, 10% talcum powder, 30% halogen-free expansion type prepared in step (1) Composite flame retardant, 0.2% antioxidant 168, 0.1% antioxidant 1010, 0.5% calcium stearate, 0.3% silicone powder; weigh the corresponding raw materials according to the above formula, add them to the high mixer and mix evenly, and...

Embodiment 2

[0023] (1) In terms of mass percentage, the formula for preparing the halogen-free intumescent compound flame retardant in this example is as follows: 60% melamine phosphate, 15% PEPA, 8% triazine char former, 7% melamine, 10% coke Phosphate; after weighing the corresponding raw materials according to the above formula, add them into the high mixer and mix them evenly to obtain the halogen-free intumescent compound flame retardant of this embodiment;

[0024] (2) In terms of mass percentage, the raw material formula for preparing the flame-retardant high-density polyethylene material in this example includes the following components: 58.5% HDPE resin, 10% talcum powder, 30% halogen-free expansion type prepared in step (1) Compound flame retardant, 0.3% antioxidant 1010, 0.5% polyethylene wax, 0.3% silicone powder; weigh the corresponding raw materials according to the above formula, add them to the high mixer and mix evenly, and then weigh 0.4% coupling agent KH560 , added...

Embodiment 3

[0026] (1) In terms of mass percentage, the formulation of the halogen-free intumescent compound flame retardant prepared in this example is as follows: 65% ammonium polyphosphate, 25% PEPA, 2% melamine cyanurate, 8% hypophosphite; The above formula weighs the corresponding raw materials and puts them into a high mixer and mixes them evenly to obtain the halogen-free intumescent compound flame retardant of this embodiment;

[0027] (2) In terms of mass percentage, the raw material formula for preparing the flame-retardant high-density polyethylene material in this example includes the following components: 58.5% HDPE resin, 10% talcum powder, 30% halogen-free expansion type prepared in step (1) Composite flame retardant, 0.2% antioxidant 168, 0.1% antioxidant 1010, 0.5% zinc stearate, 0.3% silicone powder; weigh the corresponding raw materials according to the above formula, add them to the high mixer and mix evenly, and then Weigh 0.4% coupling agent KH550, add it into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com