Trimeric cyanamide cyanureate fire retarding polyamide nano-composite meterial and its preparation method

A technology of melamine cyanurate and melamine cyanurate, which is applied in the field of melamine cyanurate flame-retardant polyamide nanocomposites and its preparation, can solve the problems of long reaction time, toxicity, and high viscosity of the system, Achieve the effects of excellent flame retardancy and mechanical properties, broad application prospects, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

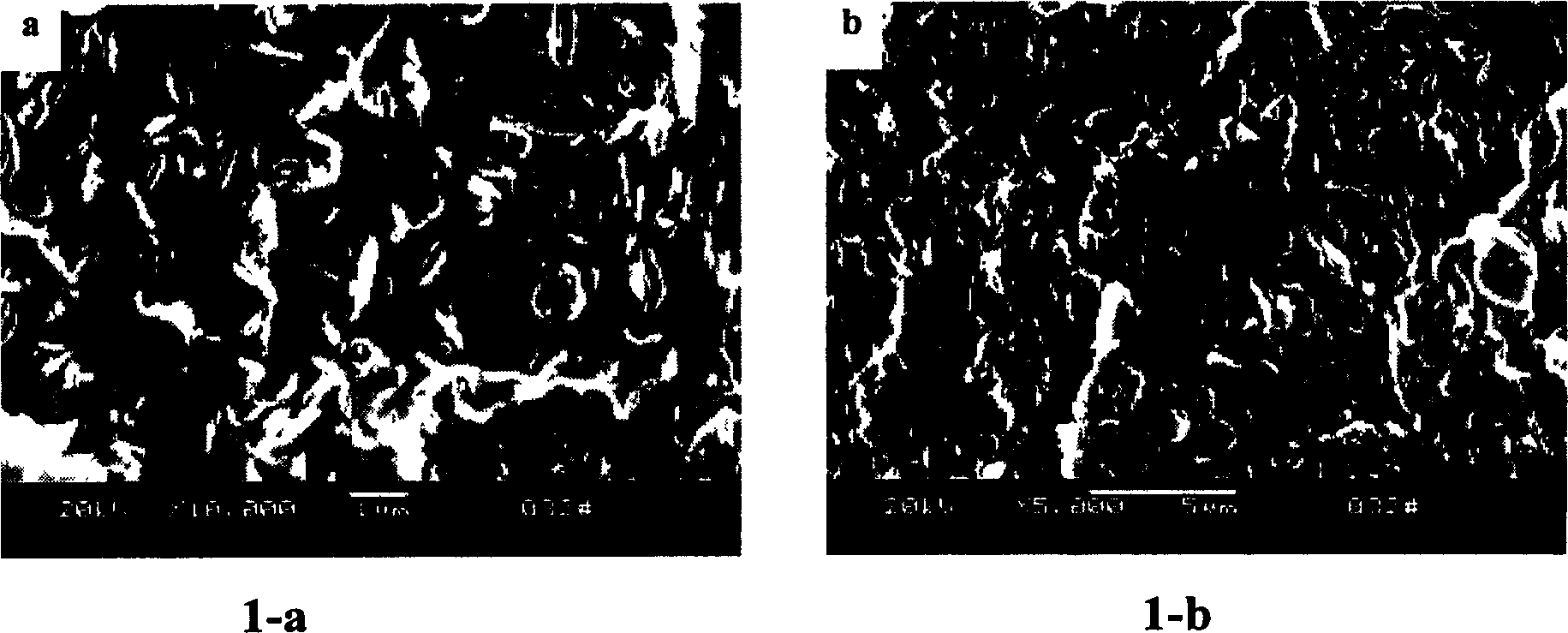

[0035]Put 0.05kg of dinonyl phthalate, 0.5kg of water and 30kg of nylon 6 into a closed container, stir, and leave it closed for 2 hours, then add 0.1kg of melamine, 0.1kg of cyanuric acid, 0.05kg of glycerin and Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.001kg, stirred, mixed evenly, then added to a twin-screw extruder, extruded and granulated at a temperature of 240°C , dried, and the obtained pellets were injected into vertical combustion splines by an injection molding machine, and the injection molding temperature was 240°C. After testing, the vertical combustion performance of the sample reached UL94 V-2 level. SEM analysis shows that the radial size of MCA particles in the flame retardant material is 50-70nm.

Embodiment 2

[0037] Put 3.6kg of dioctyl phthalate, 11.0kg of water and 200kg of nylon 66 into a closed container, stir, and leave it closed for 4 hours, then add 8.6kg of melamine, 8.6kg of cyanuric acid, 1.8kg of caprolactam, and 3.6 kg of pentaerythritol kg, 0.18 kg of tris(2,4-di-tert-butyl) phosphite and 0.10 kg of copper stearate, stirred and mixed evenly, then added to a twin-screw extruder, extruded and granulated at a temperature of 260°C, and dried , to obtain flame-retardant pellets, which are injected into vertical combustion splines by injection molding machine, and the injection molding temperature is 260°C. After testing, the vertical combustion performance of the sample reached the UL94 V-0 level. SEM analysis shows that the radial size of MCA particles in the flame retardant material is 60-80nm.

Embodiment 3

[0039] Place 50kg of diundecyl phthalate, 50kg of water and 700kg of nylon 66 in a closed container, stir, and leave it closed for 6 hours, then add 150kg of melamine, 150kg of cyanuric acid, 50kg of pentaerythritol, three (2, 10kg of 4-di-tert-butyl) phosphite and 10kg of copper acetate, stirred, mixed evenly, then added to a twin-screw extruder, extruded and granulated at a temperature of 260°C, dried to obtain flame-retardant pellets, passed through an injection molding machine Injection molded into vertical burning splines, the injection temperature is 260 ℃. After testing, the vertical combustion performance of the sample reached the UL94 V-0 level. SEM analysis shows that the radial size of MCA particles in the flame retardant material is 60-300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com