Halogen-free flame retardant thermoplastic elastomer composite material and preparation method thereof

A thermoplastic elastomer and composite material technology, applied in the direction of plastic/resin/wax insulators, conductors, insulated conductors, etc., can solve the deterioration of the mechanical properties of the flame-retardant material matrix, low flame-retardant efficiency of magnesium hydroxide, low flame-retardant efficiency, etc. problems, to achieve the effect of improving mechanical and mechanical properties, good mechanical properties, and improving flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

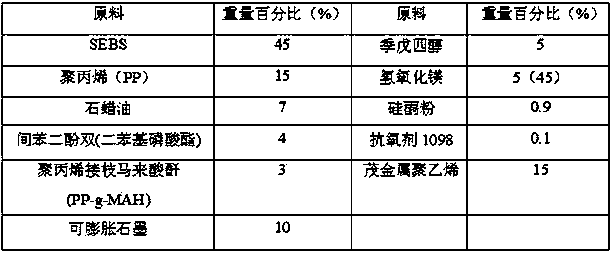

[0057] This example provides a halogen-free flame-retardant thermoplastic elastomer composite material, and its raw material formula is shown in Table 1 in terms of weight percentage:

[0058] Table 1, the raw material formula of the halogen-free flame-retardant thermoplastic elastomer composite material provided in Example 1.

[0059]

[0060] Its preparation method is as follows: 1), ingredient weighing: weigh various raw materials according to the formula. Namely, SEBS, PP, metallocene polyethylene, white mineral oil, resorcinol bis(diphenyl phosphate), PP-g-MAH, magnesium hydroxide, melamine polyphosphate, polypentyl glycol, expandable graphite , simethicone and antioxidant 168.

[0061] 2), powder mixing: mix the weighed SEBS, PP, metallocene polyethylene, white mineral oil, resorcinol bis(diphenyl phosphate), PP-g-MAH, magnesium hydroxide, melamine polyphosphate The salt, polypentyl glycol, expandable graphite, simethicone and antioxidant 168 are poured into a high...

Embodiment 2

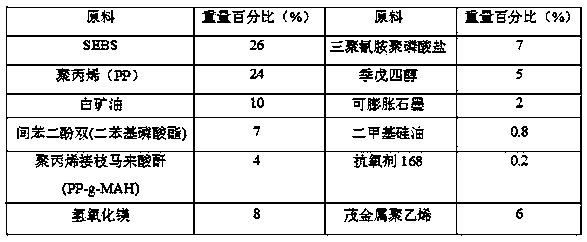

[0064] This example provides a halogen-free flame-retardant thermoplastic elastomer composite material, and its raw material formula is shown in Table 2 in terms of weight percentage:

[0065] Table 2, the raw material formula of the halogen-free flame-retardant thermoplastic elastomer composite material provided in Example 2.

[0066]

[0067] Its preparation method is as follows: 1), ingredient weighing: weigh various raw materials according to the formula. Namely SEBS, PP, metallocene polyethylene, naphthenic oil, bisphenol A bis(diphenyl phosphate), SEBS-g-MAH, zinc borate, melamine cyanurate, silicone powder and antioxidant 1010.

[0068] 2), powder mixing: mix the weighed SEBS, PP, metallocene polyethylene, naphthenic oil, bisphenol A bis(diphenyl phosphate), SEBS-g-MAH, zinc borate, melamine cyanurate , silicone powder and antioxidant 1010 are poured into a high-speed mixer and stirred evenly, and then discharged to obtain a mixed material.

[0069] 3) Extrusion gr...

Embodiment 3

[0071] This example provides a halogen-free flame-retardant thermoplastic elastomer composite material, and its raw material formula is shown in Table 3 in terms of weight percentage:

[0072] Table 3, the raw material formula of the halogen-free flame-retardant thermoplastic elastomer composite material provided in Example 3.

[0073]

[0074] Its preparation method is as follows: 1), ingredient weighing: weigh various raw materials according to the formula. Namely SEBS, PP, metallocene polyethylene, paraffin oil, bisphenol A bis(diphenyl phosphate), EVA-g-MAH, zinc borate, organic hypophosphite, polyethylene wax and antioxidant 618.

[0075] 2), powder mixing: mix the weighed SEBS, PP, metallocene polyethylene, paraffin oil, bisphenol A bis(diphenyl phosphate), EVA-g-MAH, zinc borate, organic hypophosphite, poly Ethylene wax and antioxidant 618 are poured into a high-speed mixer, stirred evenly, and discharged to obtain a mixed material.

[0076] 3) Extrusion granulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com