Daiamid composition capable of being marked by laser and preparing method thereof

A polyamide composition and laser marking technology, applied in the direction of burning, etc., can solve the problems of decreased light transmittance, decreased physical and mechanical properties, etc., and achieve the effect of maintaining performance characteristics, clear lines, and good visual effects of marking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

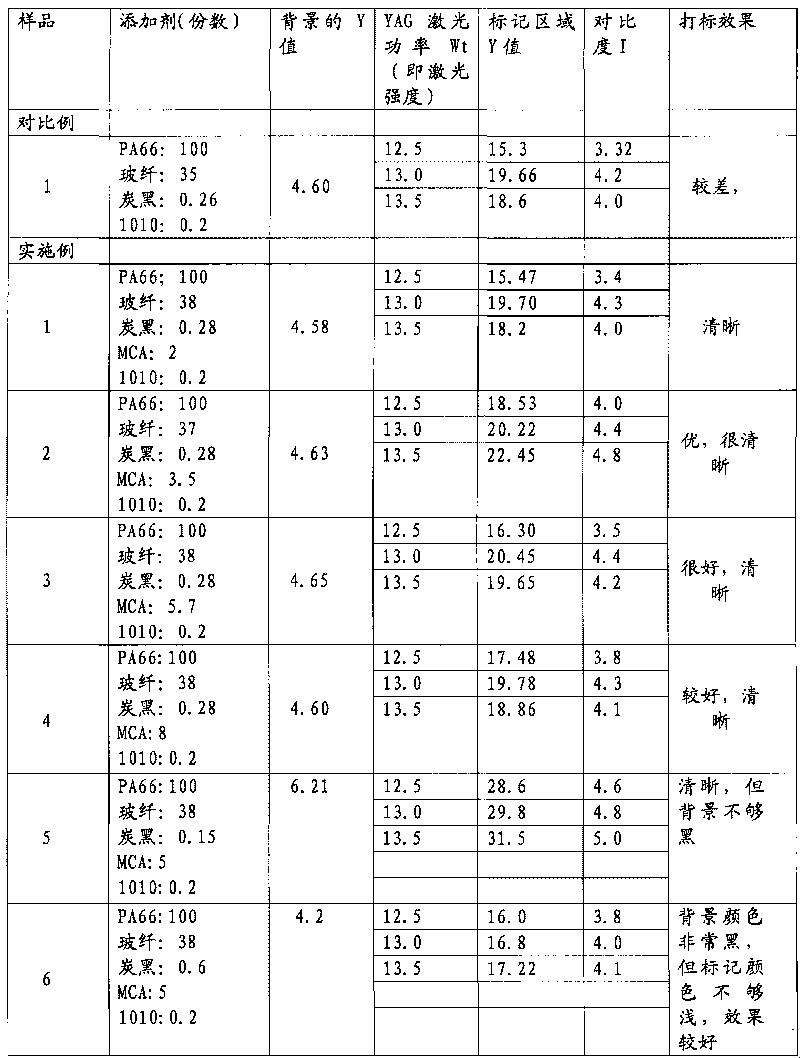

[0034] Nylon 66 (viscosity 3.2, Pingdingshan Shenma Engineering Plastics Company), carbon black (Germany, Cabot, M470), melamine cyanurate blowing agent (MelapurMC50, Ciba, Switzerland) and a small amount of antioxidant 1010 (Ciba, Switzerland) Company) placed in a high-speed mixer for physical blending, stirring evenly; put the mixture into a twin-screw extruder (Germany WP company, model ZSK-25) for melt blending and extrusion, and at the same time add Alkali-free glass fiber, the extrusion temperature is 255°C-270°C, and the screw speed is 300rpm. The extruded pellets were dried in an oven at 100°C for 8 hours, and then injected into standard specimens at a temperature of 255°C to 265°C for laser marking performance tests and related performance tests. The specific formula is shown in Table 1, wherein the contents of each component are calculated in parts by weight. The performance results are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com