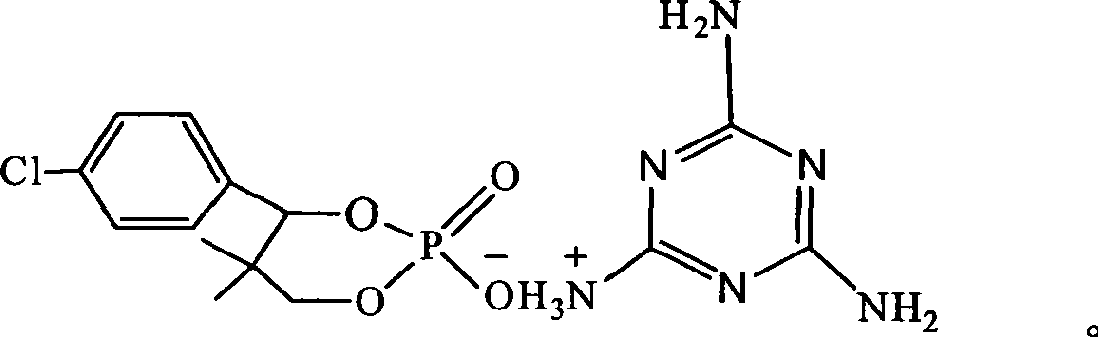

Phosphor-nitrogen expansion type combustion inhibitor and method of producing the same

A technology of nitrogen expansion and flame retardant, which is applied in the field of phosphorus-nitrogen expansion flame retardant and its preparation, can solve the problems of low thermal stability, easy decomposition, and limited application of compounds, and achieve low equipment requirements and environmental protection The effect of less pollution and less viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

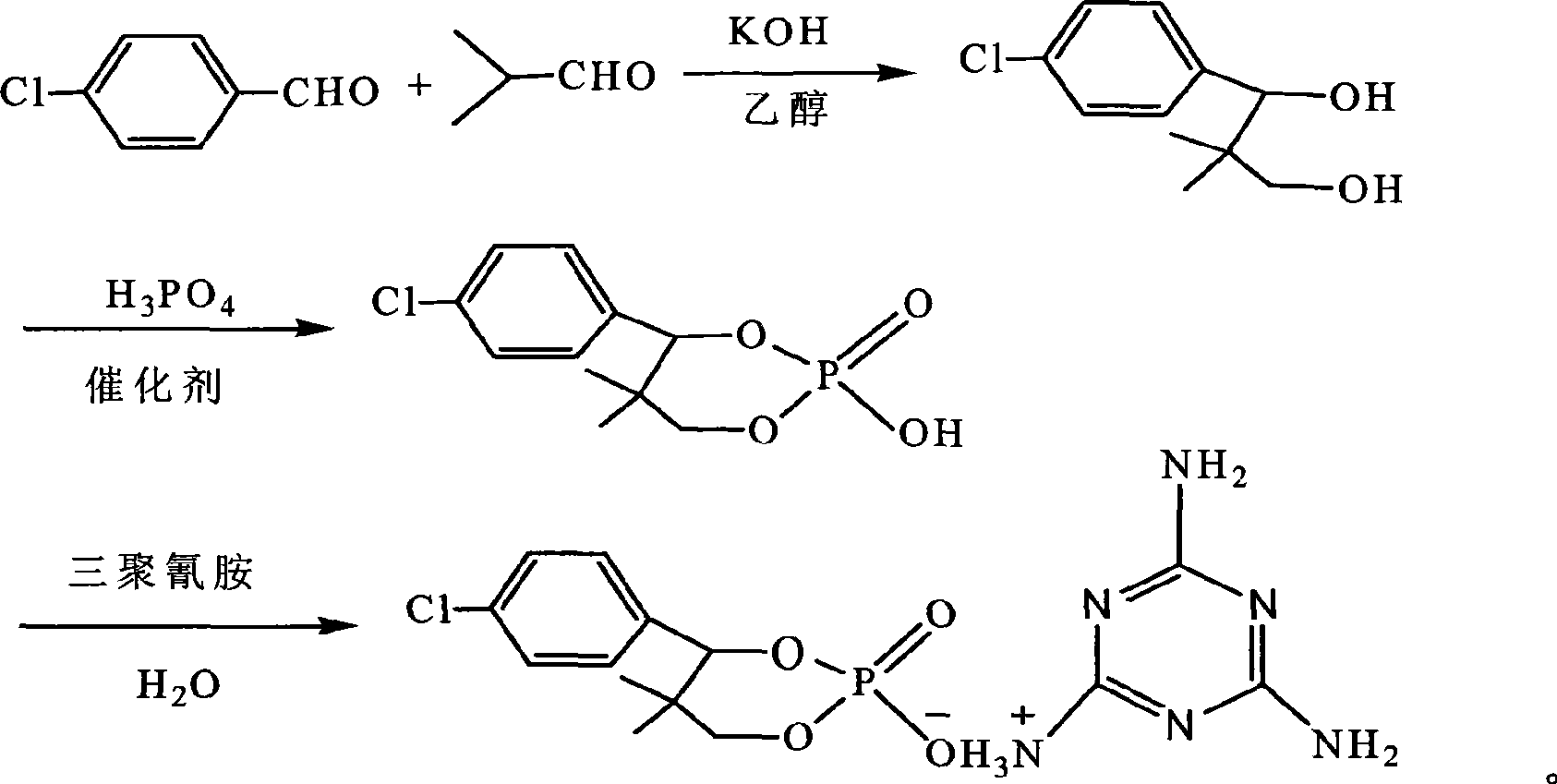

Method used

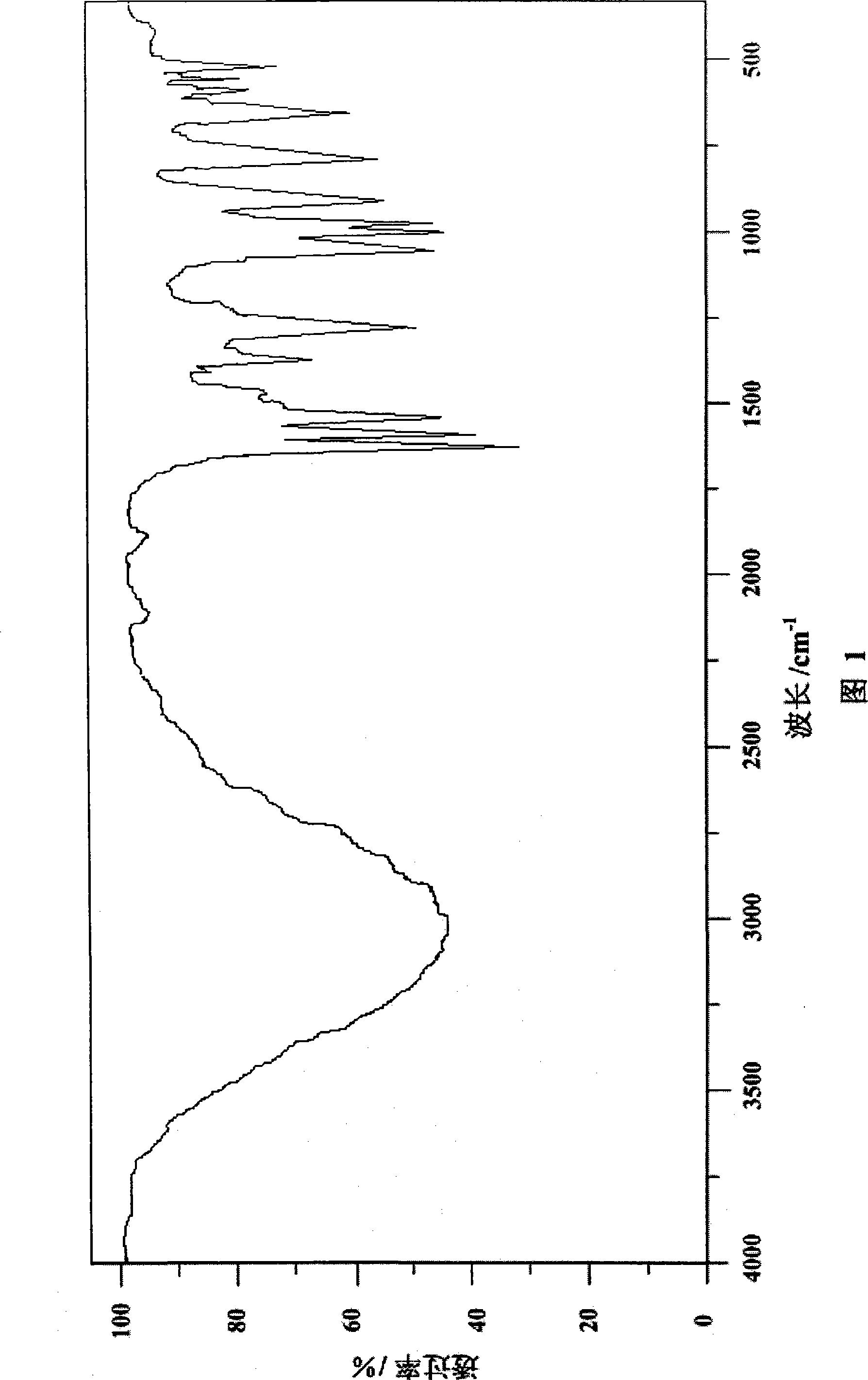

Image

Examples

Embodiment 1

[0027] 0.1 mol of p-chlorobenzaldehyde and 0.2 mol of isobutyraldehyde were mixed and placed in a 250 ml four-necked flask equipped with a thermometer, a magnetic stirrer, a reflux condenser, and a constant pressure dropping funnel. Dissolve 0.1 mol of potassium hydroxide in 90 ml of absolute ethanol, and slowly drop it into a four-necked flask with a constant pressure dropping funnel. The reaction is exothermic, and the temperature is controlled by a water bath at 50°C, and the reaction is stirred for 4 hours. After the reaction is completed, it is naturally cooled, and the reaction product is precipitated and then subjected to suction filtration. The filter cake is washed several times with n-heptane, and 19.70 g of white crystals are obtained. The product (I) has a yield of 91.84% and a melting point of 99-100°C.

[0028] Add intermediate product (I) 0.1mol, phosphoric acid 0.1mol, p-toluenesulfonic acid 0.22g, 85.8g toluene in the 250ml four-necked flask that thermometer, ...

Embodiment 2

[0031] 0.1mol of p-chlorobenzaldehyde and 0.22mol of isobutyraldehyde were mixed and placed in a 250ml four-necked flask equipped with a thermometer, a magnetic stirrer, a reflux condenser, and a constant pressure dropping funnel. Dissolve 0.12 mol of potassium hydroxide in 120 ml of absolute ethanol, and slowly drop it into a four-necked flask with a constant pressure dropping funnel. The reaction is exothermic, and the temperature is controlled by a water bath at 54°C, and the reaction is stirred for 5 hours. After the reaction is completed, it is cooled naturally, and the reaction product is precipitated and then filtered with suction. The filter cake is washed several times with n-heptane to obtain 19.75g of white crystals, namely The product (I) has a yield of 92.07% and a melting point of 98-99.5°C.

[0032] Add 0.1mol of intermediate product (I), 0.12mol of phosphoric acid, 0.43g of benzoic acid, and 108g of benzene in a 250ml four-neck flask equipped with a thermometer...

Embodiment 3

[0035] 0.1 mol of p-chlorobenzaldehyde and 0.23 mol of isobutyraldehyde were mixed and placed in a 250 ml four-necked flask equipped with a thermometer, a magnetic stirrer, a reflux condenser, and a constant pressure dropping funnel. Dissolve 0.13 mol of sodium hydroxide in 143 ml of absolute ethanol, and slowly drop it into a four-necked flask with a constant pressure dropping funnel. The reaction is exothermic, and the temperature is controlled by a water bath at 57°C, and the reaction is stirred for 5.5 hours. After the reaction is completed, it is naturally cooled, and the reaction product is precipitated and then filtered with suction. The filter cake is washed several times with n-hexane to obtain 18.90 g of white crystals, namely The product (I) has a yield of 88.11% and a melting point of 97-99.5°C.

[0036]Add intermediate product (I) 0.1mol, phosphoric acid 0.16mol, sodium p-toluenesulfonate 0.53g, 118g dimethylbenzene in the 250ml four-necked flask that thermometer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com