Flame retardant thermoplastic composition and articles comprising the same

A thermoplastic composition, the technology of the composition, applied in the mobile field, can solve problems such as adverse effects of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 10-15

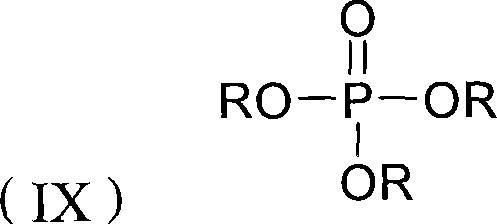

[0159] Based on thermoplastic composition with BTPP, RDP, MPP and Mg(OH) 2 Melt blended in the amounts shown in Table 3, the thermoplastic composition comprised 42.6% by weight PPE, 32.0% by weight SEBS I, 21.4% by weight LLDPE, and 4.0% by weight polybutene, based on the total weight of the thermoplastic material. BTPP, RDP, MPP and Mg(OH) 2 The amounts are shown in parts / 100 parts thermoplastic composition (PPE+SEBSI+LLDPE+polybutene). The compositions were molded into 3.2 mm bars for the flammability test and tested as described in Examples 1-9.

[0160] table 3

[0161] Example

[0162] Examples 10-15 illustrate that the combination of organophosphates is beneficial in the flame retardant additive composition and that good flame retardancy (V1 and V0) can be obtained with this flame retardant additive composition.

Embodiment 16-19

[0164] 26% by weight of PPE, 25% by weight of SEBS I, 15.0% by weight of polyethylene copolymer (as shown in Table 4) and 2% by weight of polybutene of the total weight of the composition were mixed with BTPP in the amount shown in Table 4 , RDP, MPP and Mg(OH) 2 Melt mixing. BTPP, RDP, MPP and Mg(OH) 2 The amount of is shown in weight percent of the total weight of the composition. The compositions were molded into 2.0 mm bars for the flammability test and tested as described in Examples 1-9. In Example 19, one out of ten burns resulted in dripping at 20 seconds, giving a V2 rating.

[0165] Table 4

[0166] Example

[0167] Examples 16-19 illustrate that compositions containing significant amounts of polyolefin and comprising various polyethylene copolymers can achieve a V2 rating or better using a flame retardant additive composition.

Embodiment 20

[0169] 26 wt% PPE, 25 wt% SEBS I, 15.0 wt% EEA and 2 wt% polybutene with 8.0 wt% BTPP, 12.0 wt% RDP, 5.0 wt% melaminecyanurate and 7 wt% Mg(OH ) 2 Melt mixing, wherein all weight percents are based on the total weight of the composition. The compositions were molded into 2.0 mm bars for the flammability test and tested as described in Examples 1-9. The non-self-extinguishing of the composition demonstrates that the phosphate cannot be replaced by a phosphorus-free nitrogen-containing compound, further demonstrating the surprising synergistic relationship between the three components of the flame retardant additive composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com