Method for synthesizing molecular sieve under solvent-free condition through grinding solid phase raw materials

A solvent-free and raw material-free technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of narrow synthesis range, limited application, increased production cost, etc., and achieve high yield and Increased single-pot utilization rate, huge industrial application prospects, and simplified synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of pure silicon ZSM-5 sample

[0031] First, weigh the solid raw materials: 0.285 grams of amorphous silicon dioxide, 0.5276 grams of sodium silicate nonahydrate, 0.24 grams of tetrapropylammonium bromide and 0.46 grams of ammonium chloride and pour them into a mortar, then grind and mix them for 15 minutes. Minutes later, the reaction mixture was put into a polytetrafluoroethylene-lined steel reactor, reacted at 180°C for 1 day, the reaction product was fully washed with deionized water, and dried at 80°C for more than 12 hours to obtain Final product. The chemical ratio of the system is as follows: Na 2 O:Al 2 o 3 : SiO 2 :H 2 O:R is 0.2:0:1:3:0.1.

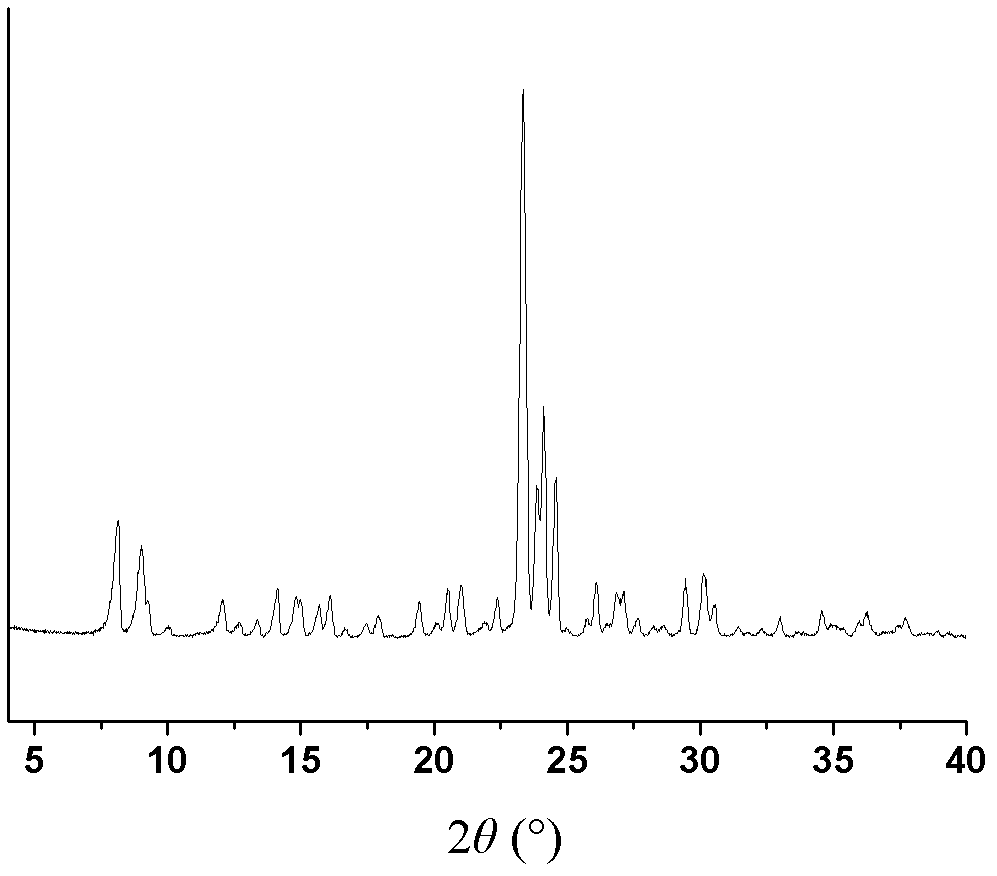

[0032] attached figure 1 According to the XRD characterization results of the product, it can be seen that the product has a typical MFI structure and has a high degree of crystallinity.

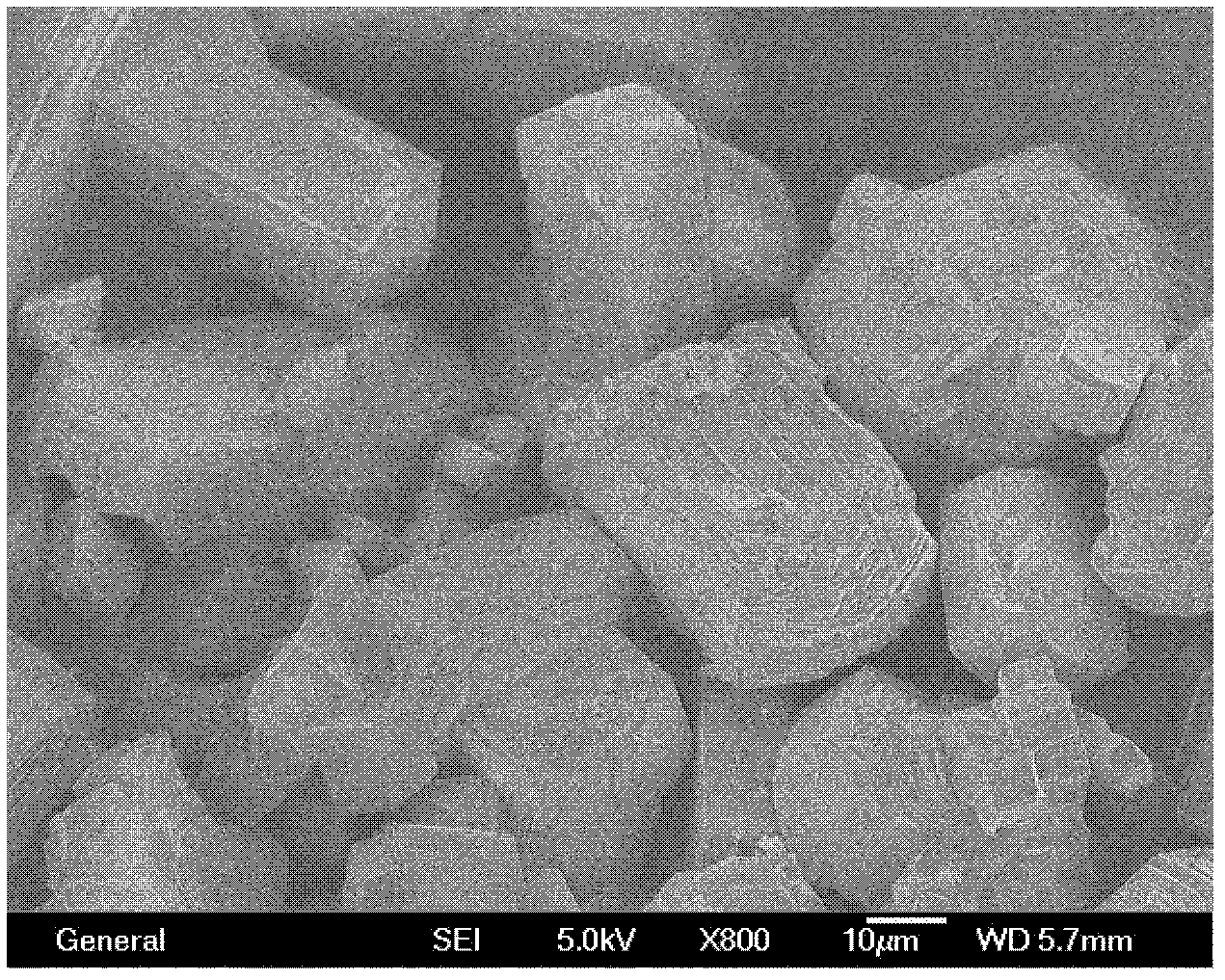

[0033] attached figure 2 It is a scanning electron microscope photo of the product, and the el...

Embodiment 2

[0034] Embodiment 2: the preparation of ZSM-5 sample containing aluminum

[0035] First solid raw materials: 0.285 gram of amorphous silicon dioxide, 1.319 gram of sodium silicate nonahydrate, 0.72 gram of tetrapropylammonium bromide, 0.013 gram of boehmite and 0.69 gram of ammonium nitrate are weighed and poured into a mortar, and then Grinding and mixing, after grinding for 15 minutes, put the reaction mixture into a polytetrafluoroethylene-lined steel reaction kettle, react at 180°C for 2 days, fully wash the reaction product with deionized water, and put it at 80°C Dry for more than 12 hours to get the final product. The chemical ratio of the system is as follows: Na 2 O:Al 2 o 3 : SiO 2 :H 2 O:R is 0.5:0.0125:1:4.5:0.3.

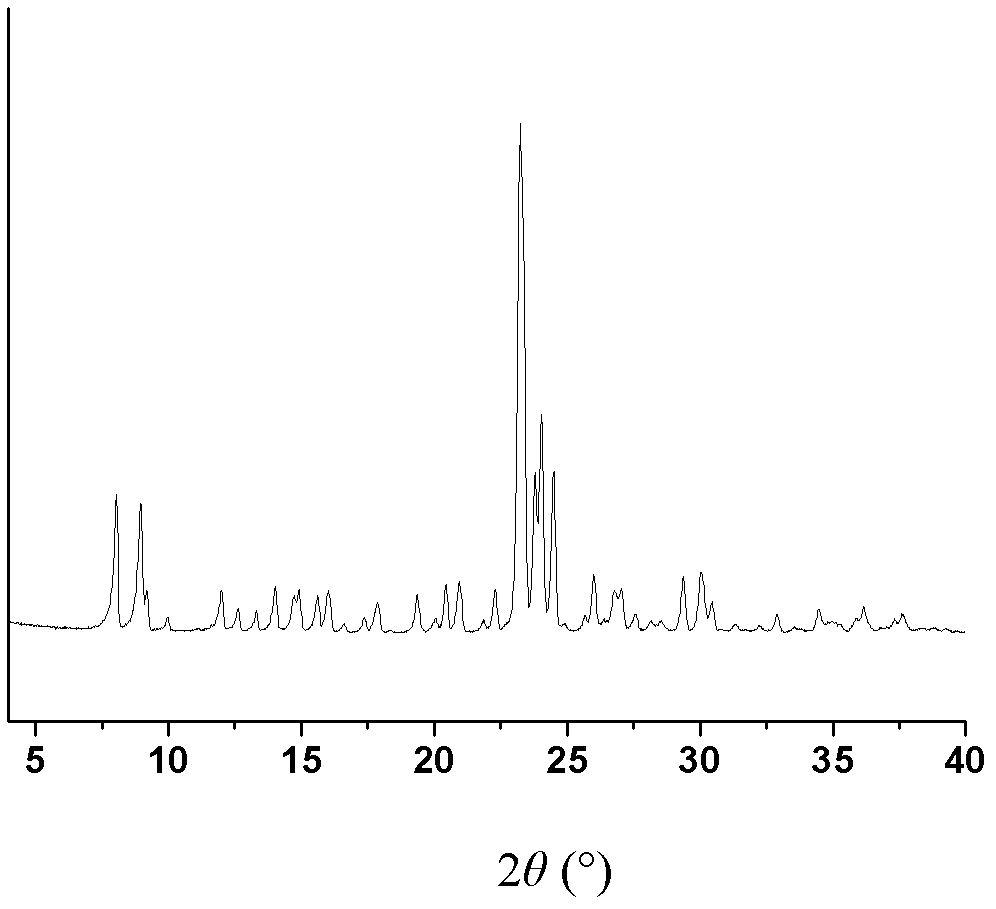

[0036] attached image 3 It is the XRD characterization result of the product, and it can be known that the product is MFI pure phase from the XRD characteristic peak.

[0037] attached Figure 4 It is a scanning electron microscope photo of the...

Embodiment 3

[0038] Embodiment 3: the preparation of ZSM-5 sample containing gallium

[0039] First, weigh the solid raw materials: 0.285 grams of amorphous silicon dioxide, 1.0552 grams of sodium silicate nonahydrate, 0.48 grams of tetrapropylammonium bromide, 0.084 grams of gallium oxide and 0.825 grams of ammonium carbonate, pour them into the mortar, and then grind After mixing and grinding for 15 minutes, the reaction mixture was put into a polytetrafluoroethylene-lined steel reactor and reacted at 180°C for 1 day. The reaction product was fully washed with deionized water and dried at 80°C for 12 hours or more to obtain the final product. The chemical ratio of the system is as follows: Na 2 O: Ga 2 o 3 : SiO 2 :H 2O:R is 0.4:0.05:1:4.5:0.2.

[0040] attached Figure 5 It is the XRD characterization result of the product, and it can be known that the product is MFI pure phase from the XRD characteristic peak.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com