Silyl ether composite defoaming agent as well as preparation method and application thereof

A technology of compound defoaming agent and defoaming agent, applied in chemical instruments and methods, composition of drilling holes, etc., can solve the problems of low surface tension, reduced surface tension of foaming liquid, poor compatibility of admixtures, etc. Safe and convenient, improve cementing quality, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

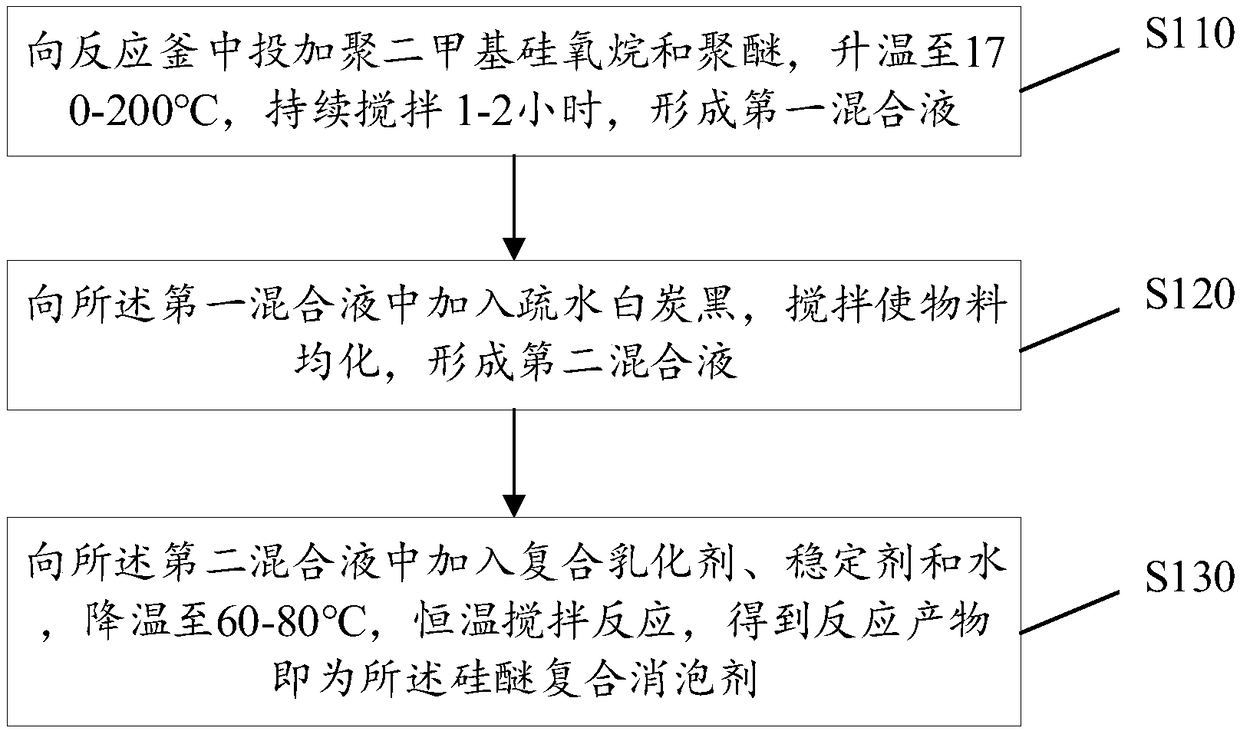

[0040] On the other hand, based on the same inventive concept, the embodiment of the present application provides a preparation method of the above-mentioned silicone ether composite defoamer, please refer to figure 1 ,include:

[0041] Step S110: adding polydimethylsiloxane and polyether to the reaction kettle, raising the temperature to 170-200° C., and continuously stirring for 1-2 hours to form a first mixed liquid;

[0042] In this step, the stirring speed is 70-90 rpm. Stir at 170-200°C for 1-2 hours to fully react polydimethylsiloxane and polyether to generate the active ingredient of the defoamer.

[0043] Step S120: adding hydrophobic silica to the first mixed solution, stirring to homogenize the materials to form a second mixed solution;

[0044] Step S130: Add a compound emulsifier, a stabilizer and water to the second mixed solution, lower the temperature to 60-80° C., stir and react at a constant temperature, and obtain a reaction product that is the silicon eth...

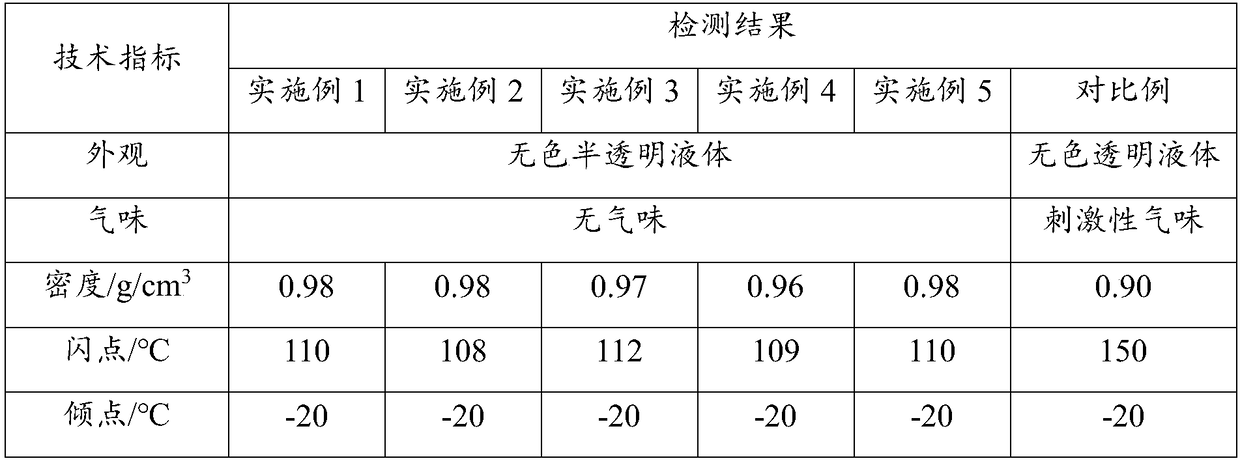

Embodiment 1

[0051] Add 15g of polydimethylsiloxane and 15g of polyether to the reaction kettle, raise the temperature to 180°C, stir at 80 rpm for 1.5 hours, add 3g of hydrophobic white carbon black, stir to homogenize the materials, and react Complete, then add 3g of complex emulsifier, 2g of stabilizer and 62g of water in sequence, lower the temperature to 70°C, stir at constant temperature, and react for 1.5 hours to obtain the silicone ether composite defoamer.

[0052] Among them, the viscosity of polydimethylsiloxane is 0.91 Pa·S; the polyether is glycerol polyoxyethylene polyoxypropylene ether, and the average molecular weight is 2500. The particle size of hydrophobic silica is 2-3μm, and the specific surface area is 190m 2 / g.

Embodiment 2

[0054] Add 20g of polydimethylsiloxane and 20g of polyether to the reaction kettle, raise the temperature to 170°C, stir at a speed of 90 rpm for 2 hours, add 4g of hydrophobic white carbon black, stir to homogenize the materials, and react Complete, then add 4g of composite emulsifier, 2g of stabilizer and 50g of water in sequence, cool down to 60°C, stir at constant temperature, and react for 2 hours to obtain the silicone ether composite defoamer.

[0055] Among them, the viscosity of polydimethylsiloxane is 0.82 Pa·S; the polyether is glycerol polyoxyethylene polyoxypropylene ether, and the average molecular weight is 1800. The particle size of hydrophobic silica is 2-3μm, and the specific surface area is 180m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com