Method for preparing nonionic surfactant with alkamine modified swill-cooked dirty oil

A non-ionic surface and waste oil technology, which is applied in the field of preparation of non-ionic surfactants, can solve problems such as polluting rivers and groundwater, food safety problems, and clogged sewers, and achieve the goals of eliminating pollution, excellent comprehensive performance, and increasing added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

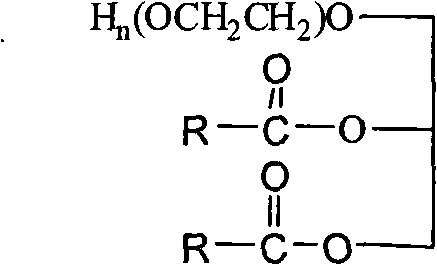

Image

Examples

Embodiment 1

[0042] 1) Refining of waste oil

[0043] Raise the temperature of the crude waste oil to 75°C, then add activated clay with a mass of 3% of the crude waste oil, stir for 20 to 30 minutes, then carry out suction filtration, transfer the grease separated by suction filtration to another reaction kettle, and then heat to 92 ℃, stirring, vacuuming to 0.4Mpa, stirring time 30-60min, when the moisture content in the oil is lower than 0.5%, it is discharged to obtain refined waste oil; the activated clay is an industrial product, the particle size is less than 200 mesh, the activity The density is greater than 140mmol / kg, and the specific surface area is 130-150m 2 / g;

[0044] 2) Amidation modification of refined waste oil

[0045] Mix the refined waste oil and monoethanolamine in a mass ratio of 100:6.3 and then add it to the reactor, and add the catalyst sodium methoxide with a quality of 0.8% of the refined waste oil to the reactor, and react at 130°C for 3 to 4 hours until the...

Embodiment 2

[0049] 1) Refining of waste oil

[0050] Raise the temperature of the crude waste oil to 90°C, then add activated clay with a quality of 4% of the crude waste oil, stir for 20 to 30 minutes, then carry out suction filtration, transfer the grease separated by suction filtration to another reaction kettle, and then heat to 94 ℃, stirring, vacuuming to 0.5Mpa, stirring time 30-60min, when the moisture content in the oil is lower than 0.5%, it is discharged to obtain refined waste oil; the activated clay is an industrial product, the particle size is less than 200 mesh, the activity The density is greater than 140mmol / kg, and the specific surface area is 130-150m 2 / g;

[0051] 2) Amidation modification of refined waste oil

[0052] Mix the refined waste oil and monoethanolamine in a mass ratio of 100:12.5 and add it to the reactor, and add the catalyst sodium ethoxide with 1% of the refined waste oil mass to the reactor, react at 140°C for 3-4 hours, and wait for the reaction t...

Embodiment 3

[0056] 1) Refining of waste oil

[0057] Raise the temperature of the crude waste oil to 80°C, then add activated clay with a mass of 5% of the crude waste oil, stir for 20 to 30 minutes, then carry out suction filtration, transfer the grease separated by suction filtration to another reaction kettle, and then heat to 92 ℃, stirring, vacuuming to 0.4Mpa, stirring time 30-60min, when the moisture content in the oil is lower than 0.5%, it is discharged to obtain refined waste oil; the activated clay is an industrial product, the particle size is less than 200 mesh, the activity The density is greater than 140mmol / kg, and the specific surface area is 130-150m 2 / g;

[0058] 2) Amidation modification of refined waste oil

[0059] Mix the refined waste oil and diethanolamine in a mass ratio of 100:11 and add them to the reactor, and add the catalyst sodium methoxide with a quality of 0.8% of the refined waste oil to the reactor, and react at 130°C for 3 to 4 hours. Obtain amidat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Activity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com