Method for making waterproof, oil-proof and antistatic polyester needled felt by magnetron sputtering-plasma

A technology of magnetron sputtering and needle-punched felt, which is applied in the direction of liquid-repelling fibers, fiber types, textiles and papermaking, can solve problems such as serious electrostatic phenomena, and achieve the increase of dynamic drape coefficient and static drape coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

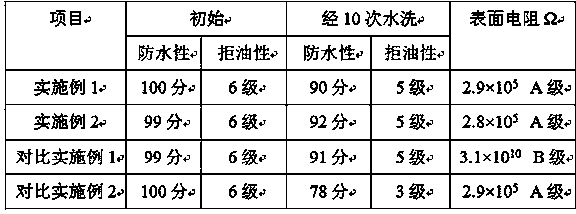

Examples

Embodiment 1

[0022] A method for making waterproof, oil-proof and antistatic polyester needle-punched felt with magnetron sputtering-plasma, characterized in that it comprises the following steps:

[0023] (1) Antistatic finishing process of polyester needle felt:

[0024] Add adhesive polyacrylate to the nano-tin antimony oxide dispersion liquid at a bath ratio of 1:50 to make a finishing liquid,

[0025] Heat it in a water bath to 44-46°C, put it into the pre-treated polyester needle felt, shake it for 30 minutes, dip it twice and roll it twice, the liquid rolling rate is 110%, pre-bake it at 80-83°C for 3 minutes, and then dry it at 115°C Bake at -125°C for 3 minutes to obtain polyester needle felt with antistatic finish;

[0026] (2) Waterproof and oil-proof finishing of polyester needle felt:

[0027] Use high-vacuum multi-functional magnetron sputtering equipment, adopt radio frequency source magnetron sputtering method, pump the vacuum chamber to vacuum and then inject argon gas. ...

Embodiment 2

[0034] A method for making waterproof, oil-proof and antistatic polyester needle-punched felt with magnetron sputtering-plasma, characterized in that it comprises the following steps:

[0035] (1) Antistatic finishing process of polyester needle felt:

[0036] Add adhesive polyacrylate to the nano-tin antimony oxide dispersion liquid at a bath ratio of 1:50 to make a finishing liquid,

[0037] Heat it in a water bath to 44-46°C, put it into the pre-treated polyester needle-punched felt, shake it for 35 minutes, dip it twice and roll it twice, the liquid rolling rate is 130%, pre-bake it at 80-83°C for 5 minutes, and then dry it at 115 Bake at -125°C for 5 minutes to obtain polyester needle felt with antistatic finish;

[0038] (2) Waterproof and oil-proof finishing of polyester needle felt:

[0039] Using high-vacuum multifunctional magnetron sputtering equipment, using radio frequency source magnetron sputtering method, the vacuum chamber is evacuated to vacuum and then fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water pressure | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com