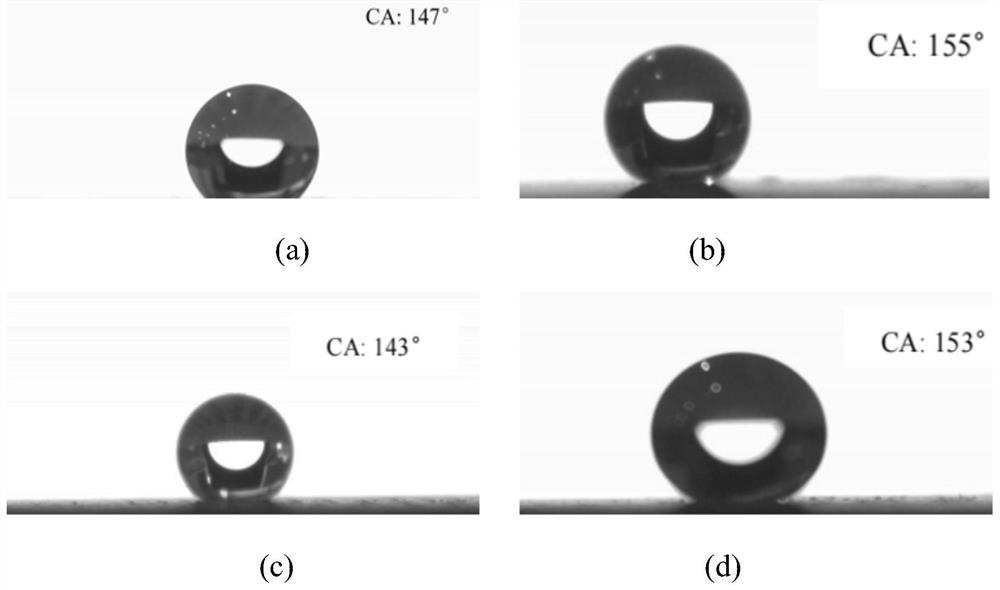

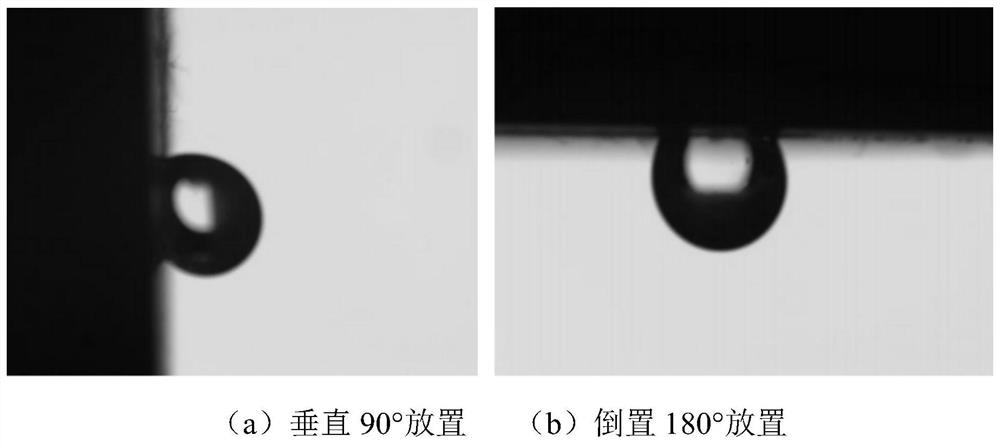

Preparation method of high-abrasion-resistant titanium alloy surface with rose petal effect

A rose petal, titanium alloy technology, applied in special surfaces, pretreated surfaces, surface reactive electrolytic coatings, etc., can solve problems such as lubricant creep loss, achieve high adhesion characteristics, high static contact angle, preparation method Simple and efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

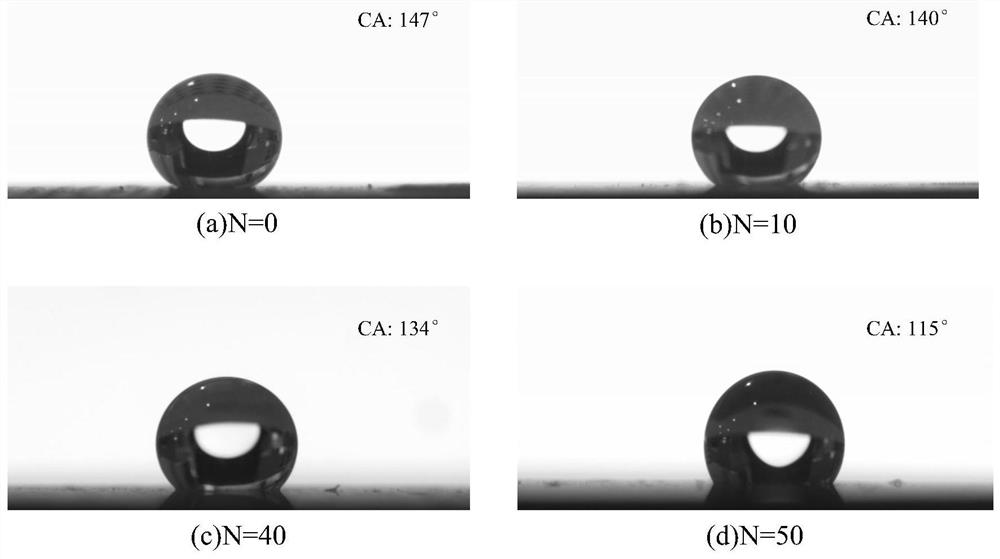

[0070] The selected specimen for the preparation of the high-adhesion surface is Ti6Al4V alloy, the industrial grade is TC4, and the titanium alloy sample of 40×40×5 (mm) is selected. The following is a specific example of preparing a high-adhesion titanium alloy surface.

[0071] A method for preparing the surface of a highly wear-resistant rose petal effect titanium alloy of the present invention is specifically implemented according to the following steps:

[0072] Step 1, titanium alloy surface pretreatment;

[0073] Step 1 is as follows:

[0074] Step 1.1, successively polish the surface of the titanium alloy test piece with 600#, 800#, 1200# metallographic sandpaper, and remove the oxide layer on the surface;

[0075] Step 1.2, the titanium alloy specimen obtained in step 1 is cleaned in an ultrasonic cleaning machine using absolute ethanol as a solvent for 5 minutes to remove surface lipids and organic matter;

[0076] Step 1.3. Rinse the surface of the titanium allo...

Embodiment 2

[0097] The selected specimen for the preparation of the high-adhesion surface is Ti6Al4V alloy, the industrial grade is TC4, and the titanium alloy sample of 40×40×5 (mm) is selected. The following is a specific example of preparing a high-adhesion titanium alloy surface.

[0098] A method for preparing the surface of a highly wear-resistant rose petal effect titanium alloy of the present invention is specifically implemented according to the following steps:

[0099] Step 1, titanium alloy surface pretreatment;

[0100] Step 1 is as follows:

[0101] Step 1.1, successively polish the surface of the titanium alloy test piece with 600#, 800#, 1200# metallographic sandpaper, and remove the oxide layer on the surface;

[0102] Step 1.2, the titanium alloy specimen obtained in step 1 is cleaned in an ultrasonic cleaning machine using absolute ethanol as a solvent for 5 minutes to remove surface lipids and organic matter;

[0103] Step 1.3. Rinse the surface of the titanium alloy ...

Embodiment 3

[0122] The selected specimen for the preparation of the high-adhesion surface is Ti6Al4V alloy, the industrial grade is TC4, and the titanium alloy sample of 40×40×5 (mm) is selected. The following is a specific example of preparing a high-adhesion titanium alloy surface.

[0123] A method for preparing the surface of a highly wear-resistant rose petal effect titanium alloy of the present invention is specifically implemented according to the following steps:

[0124] Step 1, titanium alloy surface pretreatment;

[0125] Step 1 is as follows:

[0126] Step 1.1, successively polish the surface of the titanium alloy test piece with 600#, 800#, 1200# metallographic sandpaper, and remove the oxide layer on the surface;

[0127] Step 1.2, the titanium alloy specimen obtained in step 1 is cleaned in an ultrasonic cleaning machine using absolute ethanol as a solvent for 5 minutes to remove surface lipids and organic matter;

[0128] Step 1.3. Rinse the surface of the titanium allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com