Anti-condensation coating and preparation method thereof

An anti-condensation and coating technology, applied in coatings and other directions, can solve the problems of short duration of anti-condensation performance and loss of hydrophobic properties, and achieve long-lasting anti-condensation effect, excellent weather resistance, and good solvent resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

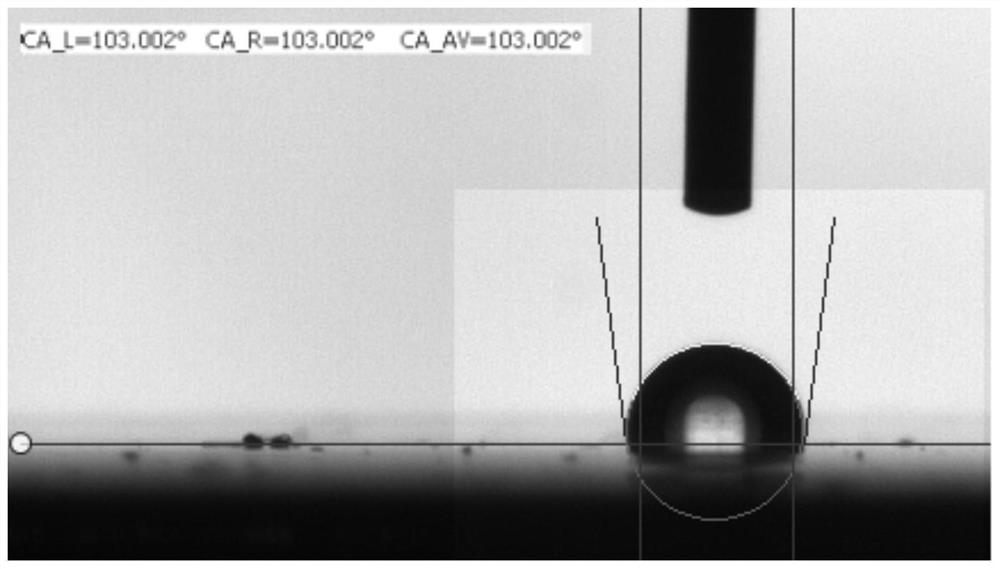

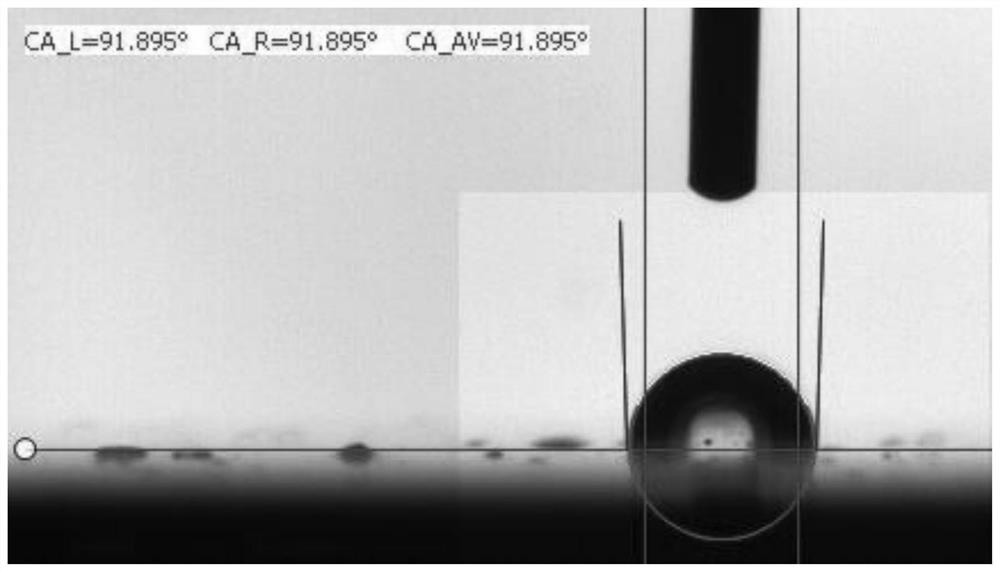

Image

Examples

Embodiment 1

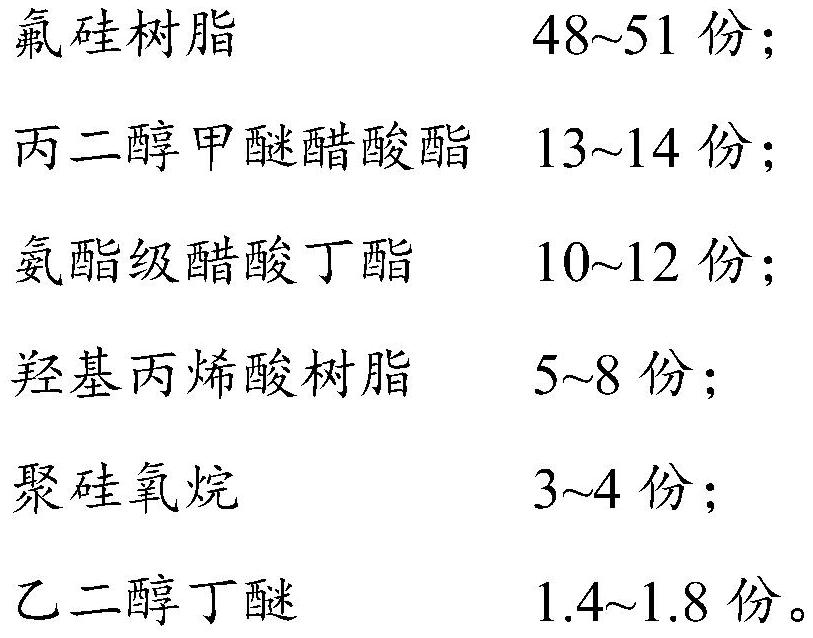

[0038] This embodiment provides an anti-condensation coating, which is used in electric equipment with low surface energy and long-term anti-condensation. Component A of the anti-condensation coating is mixed with the following substances by weight and filtered through a 80-100 mesh filter production:

[0039] 5-8 parts of 4470 hydroxy acrylic resin, 48-51 parts of fluorosilicone resin, 13-14 parts of propylene glycol methyl ether acetate (PMA), 10-12 parts of urethane grade butyl acetate, 1.4-1.8 parts of Ethylene glycol butyl ether, 0.2-0.4 parts of dispersant, 0.45-0.55 parts of defoamer, 0.45-0.55 parts of defoamer, 0.25-0.35 parts of leveling agent, 0.1-0.2 parts of TIN~22 curing Accelerator, 0.3~0.4 parts of PPB adhesion promoter, 10~11 parts of 998 titanium dioxide, 0.1~0.2 parts of MA~100 carbon black, 0.05~0.1 parts of 501 lemon yellow, 0.1~0.2 parts of R~ 972 anti-settling agent, 3-4 parts of DG5001 polysiloxane.

[0040] In this embodiment, the dispersant, defoame...

Embodiment 2

[0044] A kind of preparation method of anti-condensation coating is as follows:

[0045] (1) Take 14 parts by weight of propylene glycol methyl ether acetate, 11 parts of urethane grade butyl acetate and 7 parts of 4470 hydroxyl acrylic resin and join in the dispersing device and stir evenly;

[0046] (2) Then add 0.3 parts by weight of P104S dispersant, 0.5 parts of 5500 defoamer, 0.5 part of 6800 defoamer, 0.3 part of 835 leveling agent, 10.5 parts of 998 titanium dioxide, 0.2 parts of MA~100 carbon black and 0.1 part of 501 tartrazine were dispersed at a speed of 500r / min for 25 minutes to form a uniform dispersion;

[0047] (3) Add the homogeneously dispersed slurry in step (2) into the conical mill and grind until the fineness reaches 80 microns and then add to the dispersion container;

[0048](4) Then weigh 50 parts by weight of fluorosilicone resin, 0.1 parts of TIN~22 curing accelerator, 0.3 parts of PPB adhesion promoter, 1.5 parts of ethylene glycol butyl ether and...

Embodiment 3

[0052] A kind of preparation method of anti-condensation coating is as follows:

[0053] (1) Take by weight 13.5 parts of propylene glycol methyl ether acetate, 10.5 parts of urethane grade butyl acetate and 6.5 parts of 4470 hydroxyl acrylic resin and join in the dispersion device and stir evenly;

[0054] (2) Then add 0.35 parts by weight of P104S dispersant, 0.45 parts of 5500 defoamer, 0.45 parts of 6800 defoamer, 0.25 parts of 835 leveling agent, 10 parts of 998 titanium dioxide, 0.15 parts of MA~100 carbon black and 0.08 parts of 501 tartrazine were dispersed at a speed of 900r / min for 30 minutes to form a uniform dispersion;

[0055] (3) Add the homogeneously dispersed slurry in step (2) into the conical mill and grind until the fineness reaches 90 microns and then add to the dispersion container;

[0056] (4) Weigh again 49 parts by weight of fluorosilicone resin, 0.1 parts of TIN~22 curing accelerator, 0.3 parts of PPB adhesion promoter, 1.45 parts of ethylene glycol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com