Core-shell anti-infrared auxiliary agent, heat-insulation EVA non-flowing glue film and preparation method

An infrared, core-shell technology, applied in the direction of adhesives, adhesive additives, film/flake adhesives, etc., can solve the problems of burning material, uneven temperature distribution, serious flow of glue, etc., and achieve the performance of shielding infrared rays and ultraviolet rays. Improve the effect of shielding ultraviolet and infrared rays and improving the uniformity of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

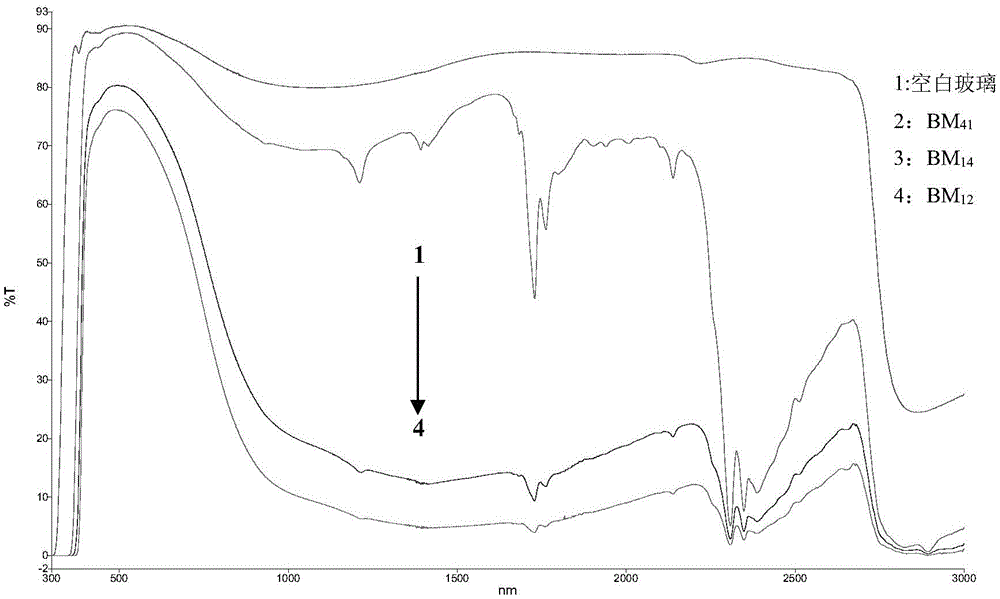

Image

Examples

Embodiment 1-6

[0041] Prepare the core-shell type anti-infrared auxiliary agent as follows:

[0042] (1) EVA resin is added into an organic solvent so that the content of the EVA resin is 8-12wt%, and then reflux at 120-150° C. for 10-30 min to obtain an EVA resin binder.

[0043] (2) W with a particle size of 30-90mm x Ce y -ATO is added to the organic solvent and makes W x Ce y - The content of ATO is 15-30wt%, and then the mixture is placed in an ultrasonic apparatus and dispersed by ultrasonic waves for 10-20 minutes, and then the mixture is placed on a high-speed sand mill to circulate and disperse for 5-8 hours to obtain nano heat-insulating slurry.

[0044] (3) Evenly mix 60-90 parts of EVA resin binder with 10-40 parts of nano heat-insulating slurry to obtain a core-shell type anti-infrared auxiliary agent.

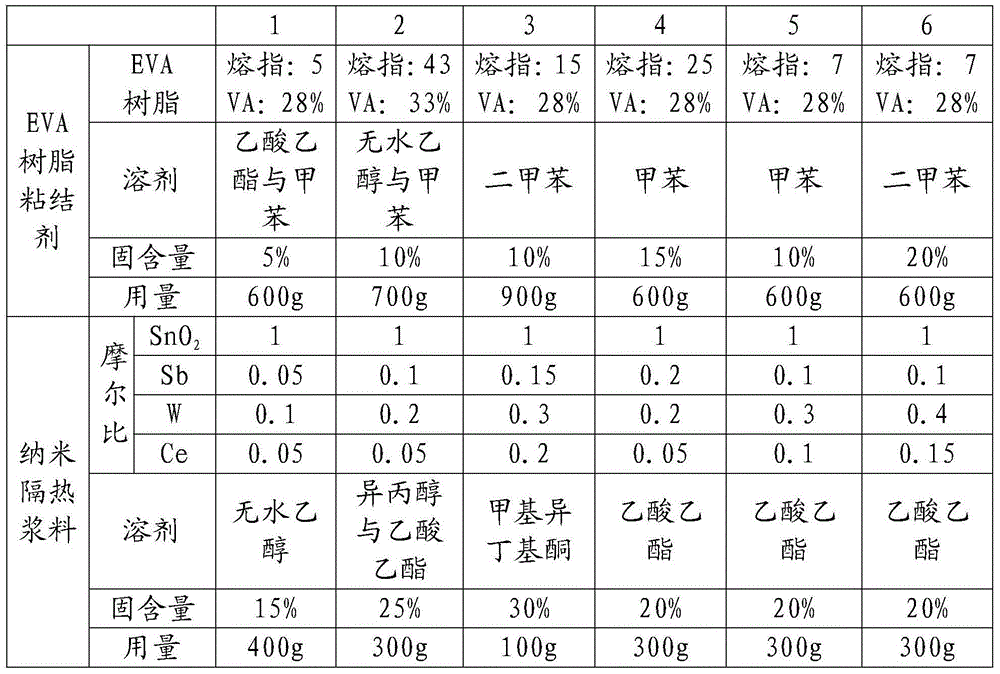

[0045] The components and their specific dosages in Examples 1-6 are shown in Table 1 below.

[0046] Table 1 Components and dosages of core-shell anti-infrared additives p...

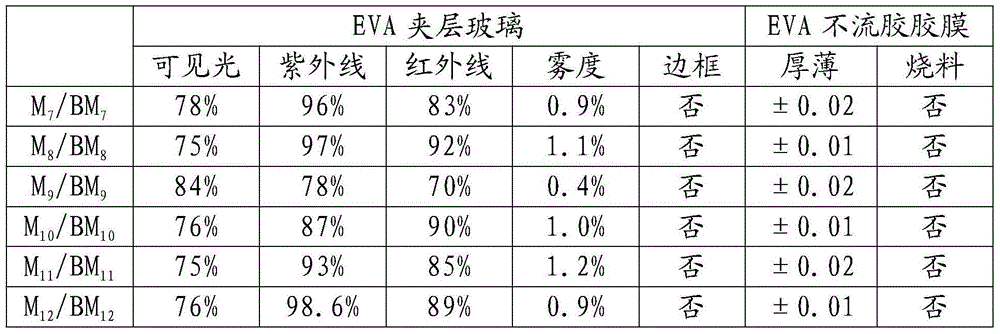

Embodiment 7-12

[0051] The core-shell type anti-infrared auxiliary agent d prepared by applying the above-mentioned embodiments respectively 1-6 Prepare heat-insulating EVA non-flow adhesive film as follows:

[0052] (1) In a horizontal high-speed mixer, 2Kg of EVA resin (KA-31, VA28%, melt index 7g / 10min) and 60g of core-shell type anti-infrared auxiliary agent are mixed uniformly, and continue to stir until the mixture is dry ( Stir at room temperature for more than 5 minutes, such as stirring for 10 minutes or 30 minutes, etc.), to obtain the initial material.

[0053] (2) 12g coupling agent a 1 , 16g crosslinking agent b 1 and 12g UV absorber c 1 Mix evenly to obtain a mixture of additives; then mix the mixture of additives and the starting material evenly, and continue to stir until the mixture is dry (stirring at room temperature for more than 5 minutes, such as stirring for 10 minutes or 30 minutes, etc.), to obtain a coarse material.

[0054] (3) Use a suction machine to pump the ...

Embodiment 13-32

[0064] Prepare heat-insulating EVA non-flow adhesive film as follows:

[0065] (1) Mix 2Kg of EVA resin and core-shell anti-infrared additives evenly in a horizontal high-speed mixer, and continue stirring until the mixture is dry (stirring at room temperature for more than 5 minutes, such as stirring for 10 minutes or 30 minutes, etc.), to obtain the initial material.

[0066] (2) Mix the coupling agent, cross-linking agent and ultraviolet absorber evenly to obtain the auxiliary agent mixture; then mix the auxiliary agent mixture and the initial material evenly, and keep stirring until the mixture is dry (stirring at room temperature for more than 5 minutes, such as stirring for 10 minutes or 30min, etc.), to obtain coarse material.

[0067] (3) Use a suction machine to pump the coarse material into the single-screw extruder, and control the screw temperature of the single-screw extruder at 85-100°C, heat the die head through an oil bath and control the die head temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com