Device for automatically lacquering external case of frontend wall of shipping container

An automatic painting and container technology, which is applied in spraying devices, devices for coating liquid on the surface, coatings, etc., can solve the problems of low production efficiency, high labor intensity, poor spraying effect, etc., and achieve extended service life and high spraying quality Good, high spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

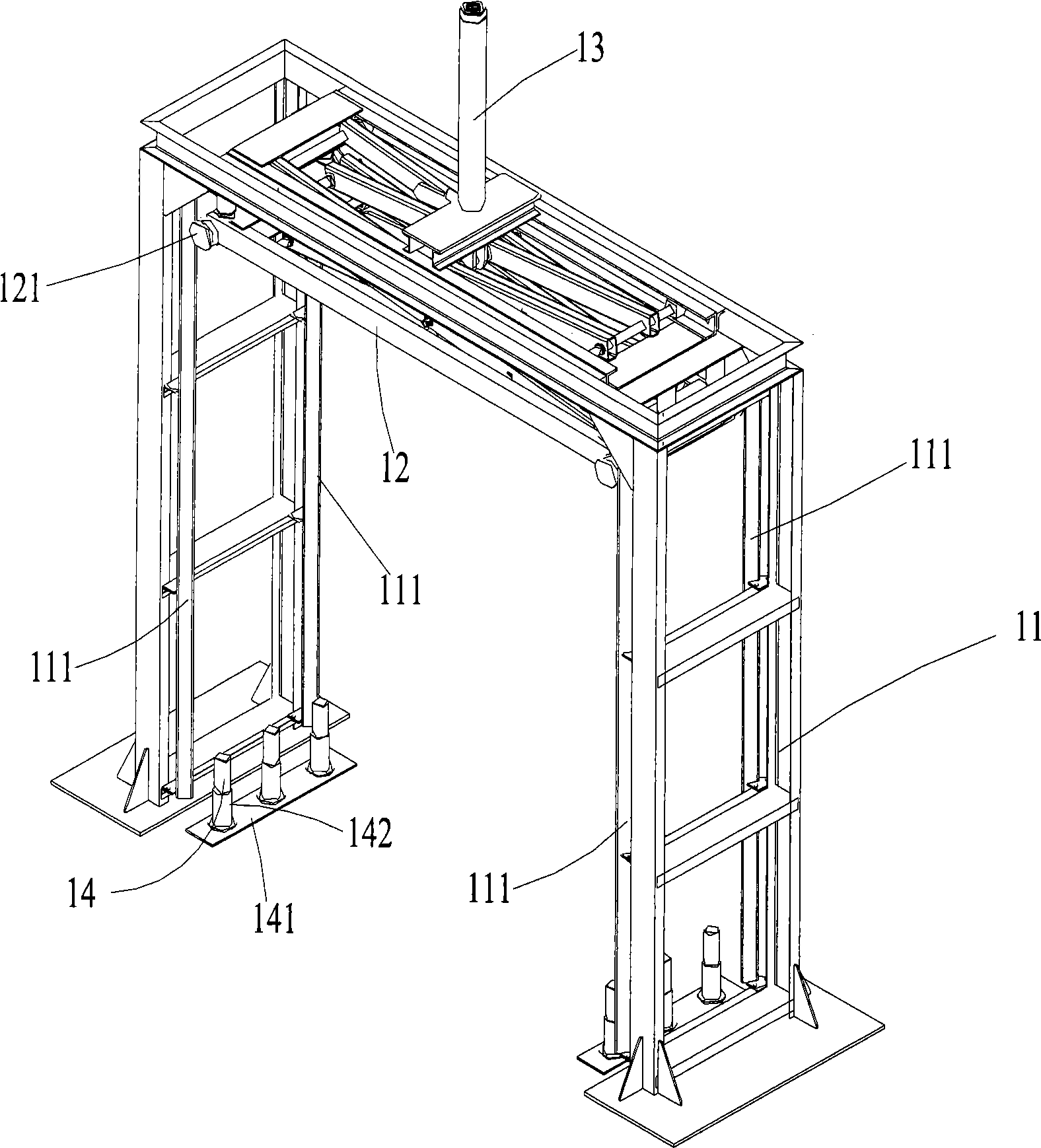

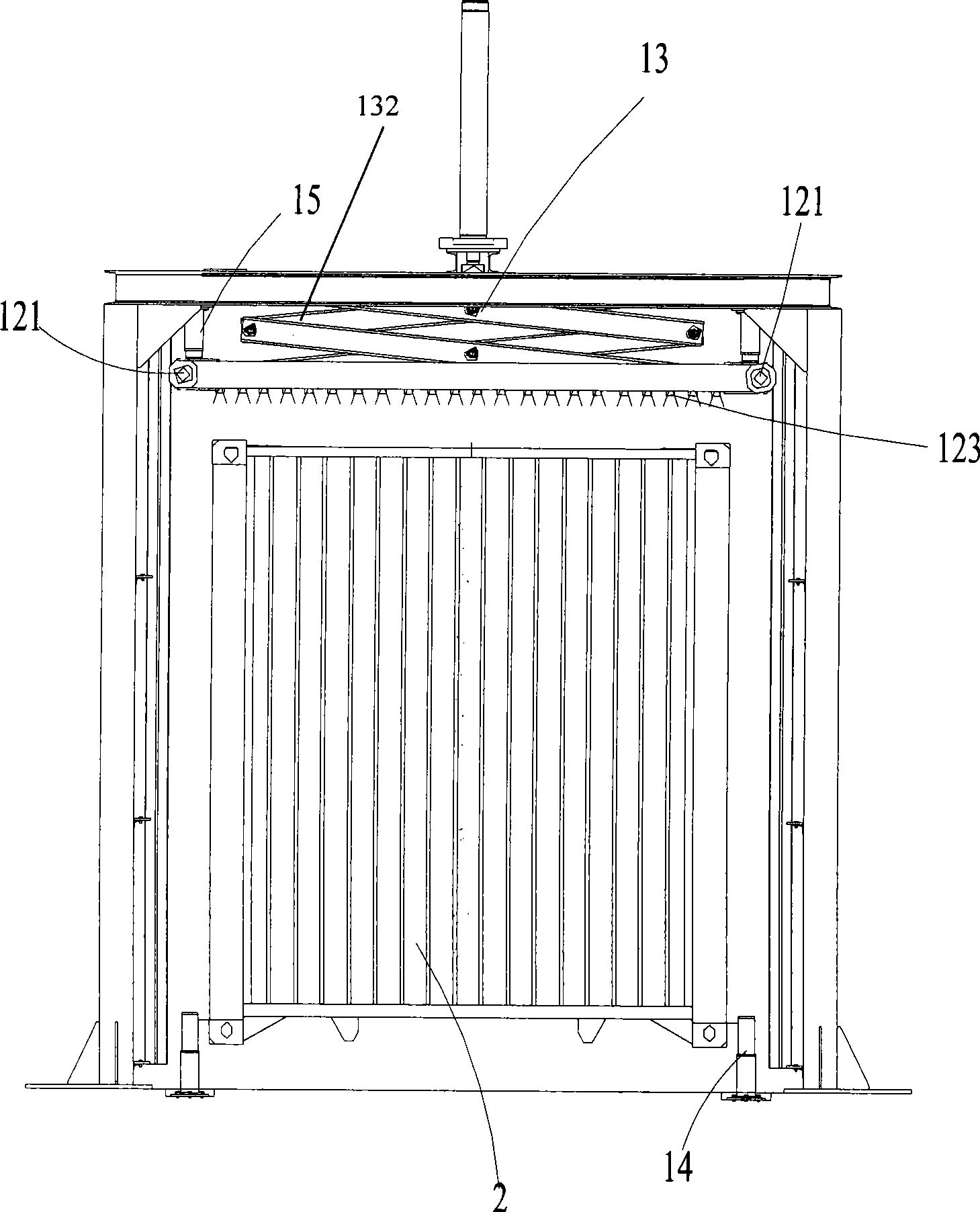

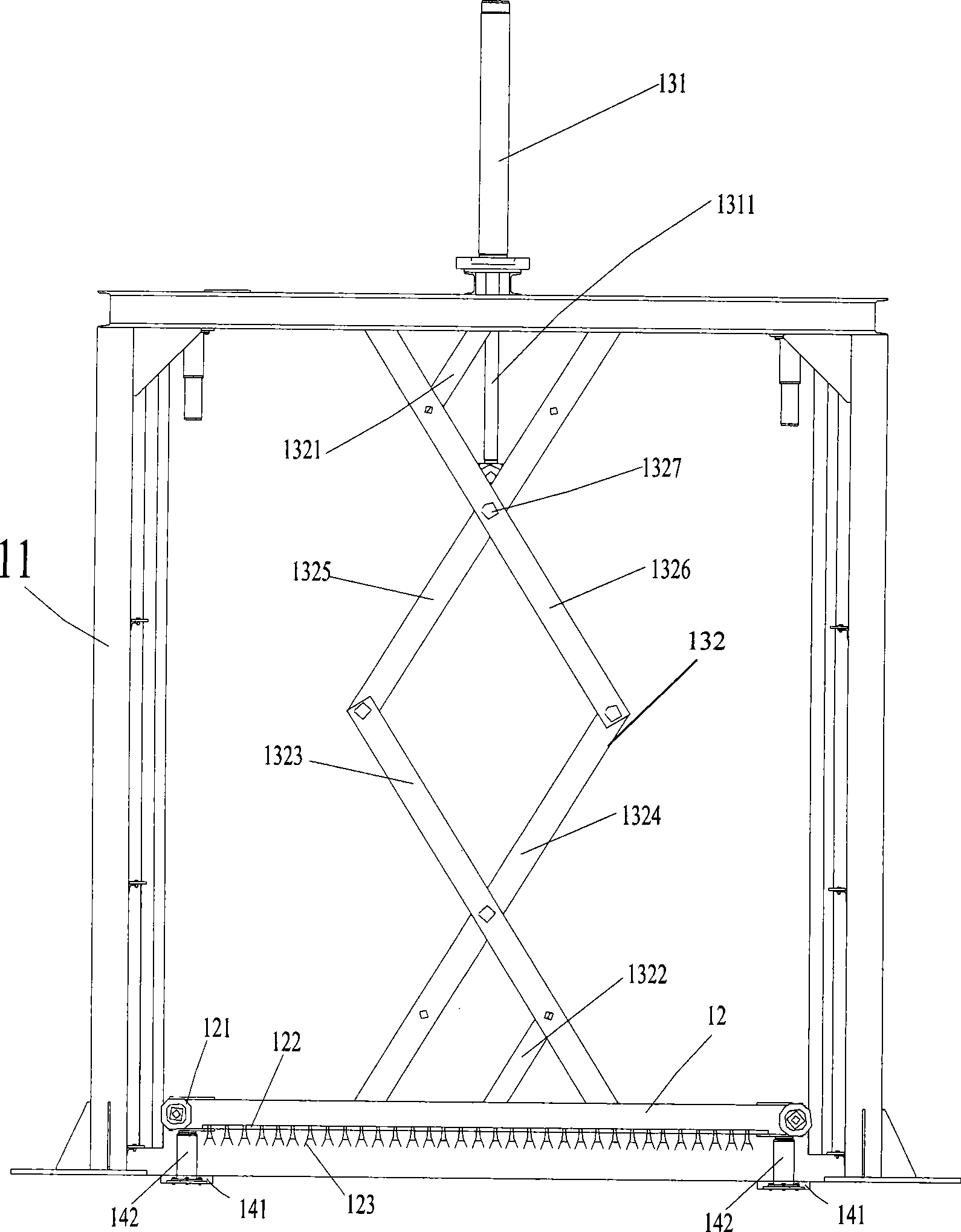

[0017] See figure 1 with figure 2 , The present invention includes a gantry frame 11, a spray gun bracket 12 is horizontally arranged on the inner side of the gantry frame 11, and a driving device 13 is provided on the top of the gantry frame 11, and the driving device 13 is connected to the spray gun bracket 12, and A plurality of spray guns 123 with adjustable angles are horizontally arranged on the side of the spray gun bracket 12 corresponding to the front wall 2 of the container; under the action of the driving device 13, the spray gun bracket 12 drives the spray gun 123 to reciprocate up and down along the gantry frame 11 .

[0018] The gantry frame 11 matches the shape of the container end 2 and at least the container front wall 2 can be accommodated inside. Linear guide rails 111 are respectively provided on the two inner longitudinal side walls of the gantry frame 11 perpendicular to the ground. There are rollers 121 engaged with the linear guide at the joints of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com