Full casing long-spiral bored pile machine and method of using same for construction

A technology of long helical drilling and long helical drilling, which is applied to drilling equipment and methods, rotary drilling rigs, percussion drilling, etc., and can solve the problem that the surrounding soil is prone to water gushing into the hole, the hole is easy to collapse, and the cement slurry is easy to infiltrate and other problems to achieve the effect of eliminating water gushing in the hole and preventing uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

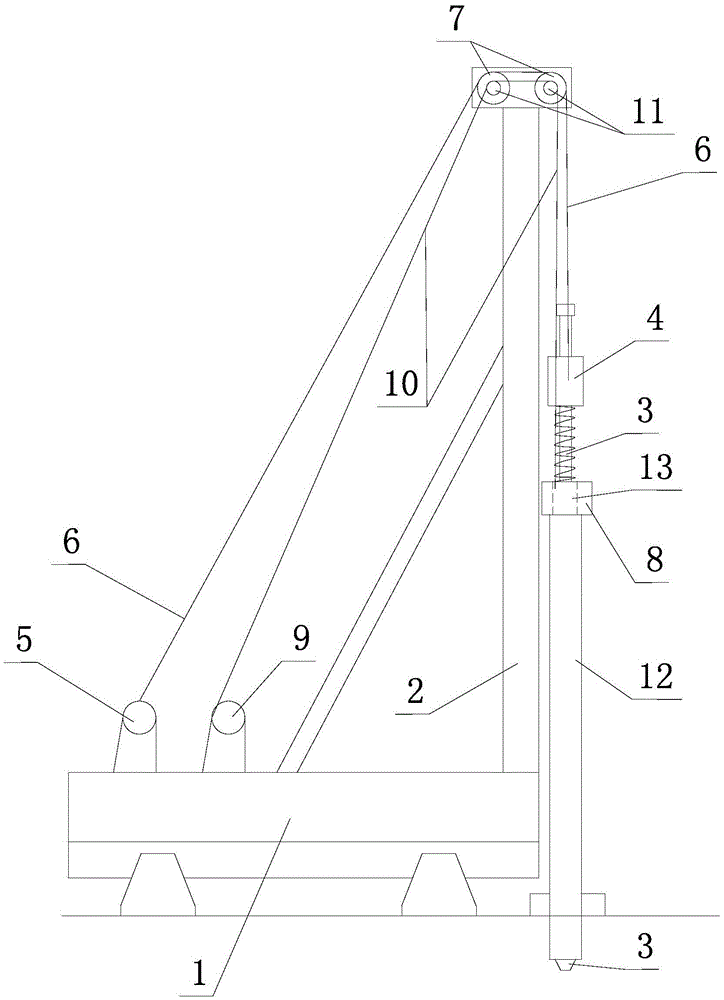

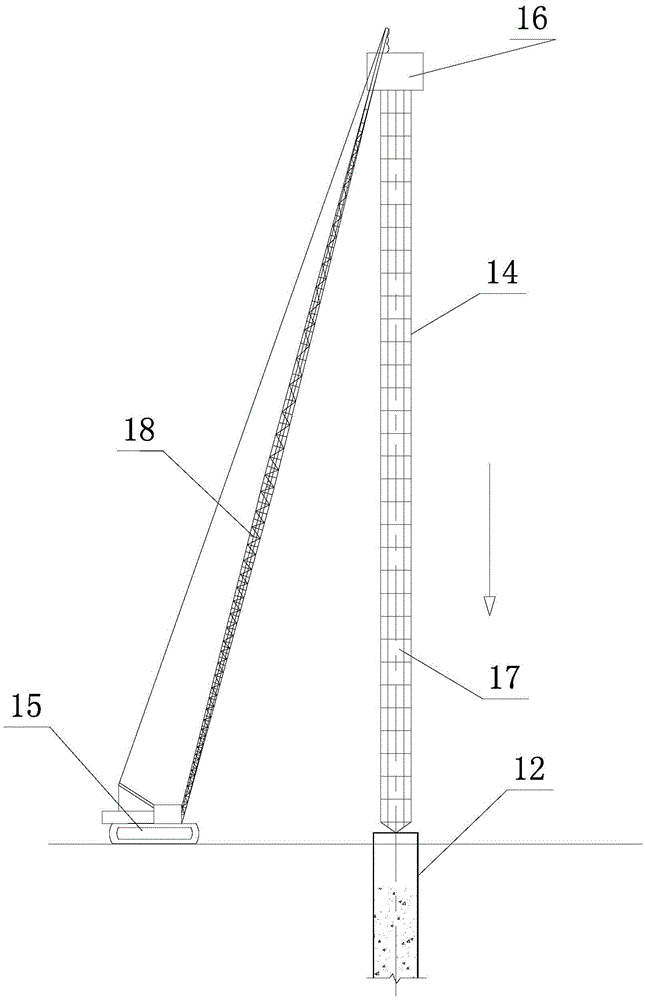

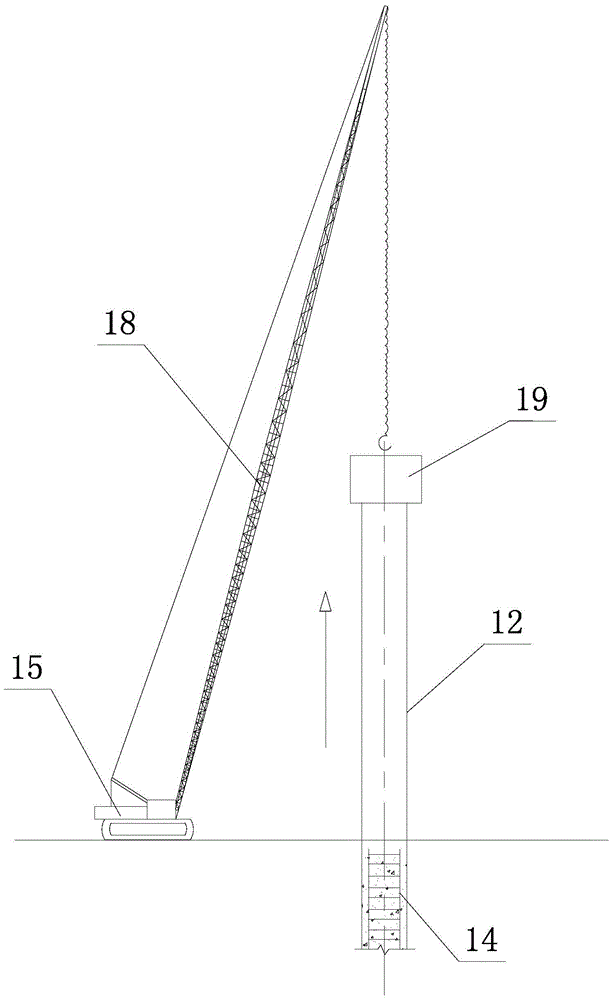

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 As shown, the full casing type long helical drilled pile driver of the present invention comprises a chassis 1, a main mast 2, a long helical drill rod 3, an upper power head 4, a first winch 5, a first traction rope 6, and a lower power head 8 , The second winch 9 and the second traction rope 10. The main mast 2 is fixed on the chassis 1, the top of the main mast 2 is provided with a first fixed pulley block 7 and a second fixed pulley block 11, both pulley blocks are provided with front and rear pulleys, and the two pulleys of the first fixed pulley block 7 are in the second One side of the two pulleys of the fixed pulley block 11, such a design is convenient for the first traction rope 6 and the second traction rope 10 to be staggered mutually.

[0024] Both the upper power head 4 and the lower power head 8 are slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com