Aluminum template system for building

A technology for aluminum formwork and construction. It is applied in the direction of construction, building structure, formwork/formwork/work frame, etc. It can solve the problems of affecting construction efficiency, inconvenient assembly and disassembly, and long time for disassembling the formwork, so as to improve construction efficiency. , easy to dismantle, and improve the effect of turnover rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

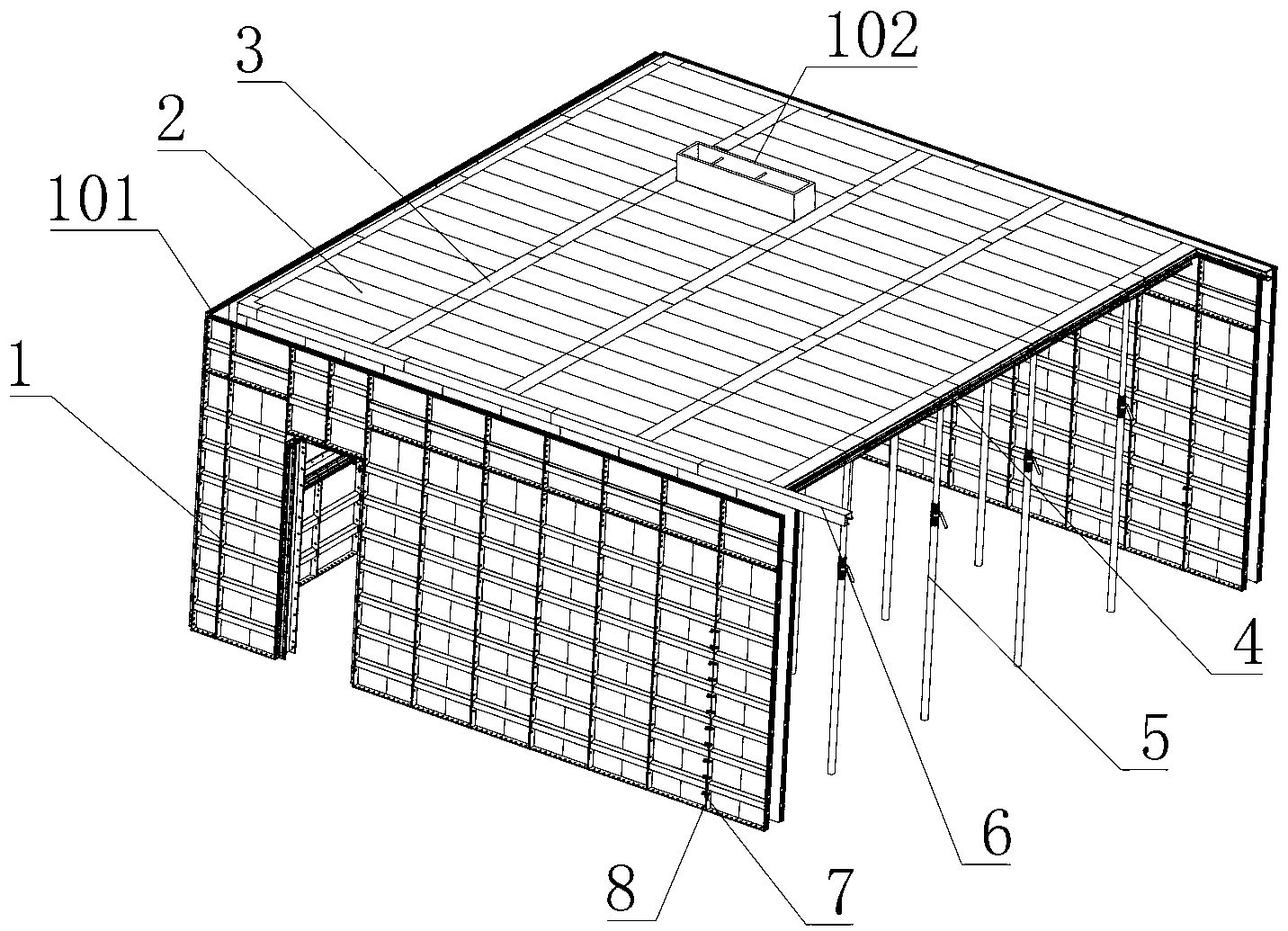

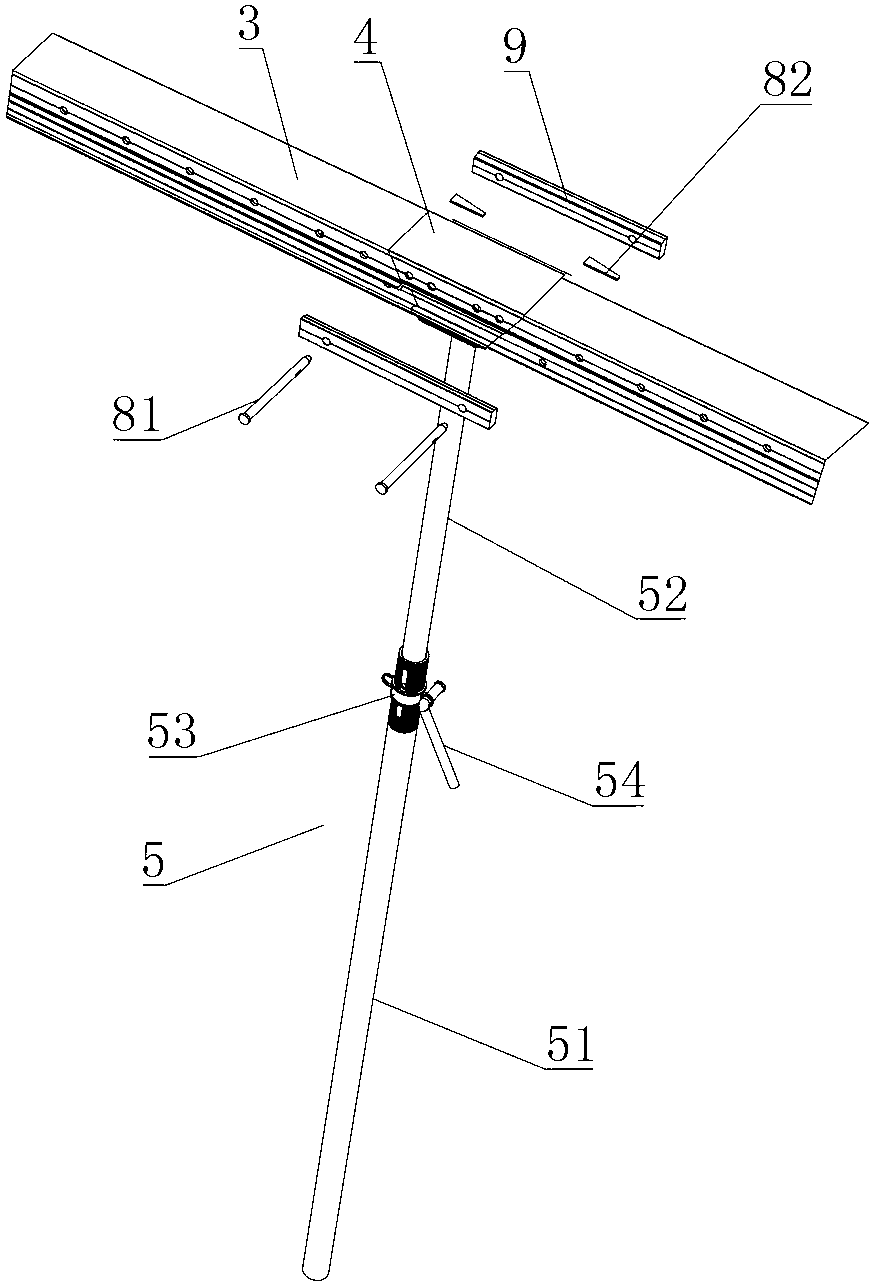

[0046] Such as Figure 1 to Figure 13 As shown, the building aluminum formwork system of the present invention includes a wall panel 1 with an L-shaped corner 10 at the bottom, a floor panel 2, and a support structure for supporting the floor panel 2. The support structure includes end beams 3, The support column 5 and the plug cover 4 arranged at the top of the support column 5 and connected with the end beam 3 .

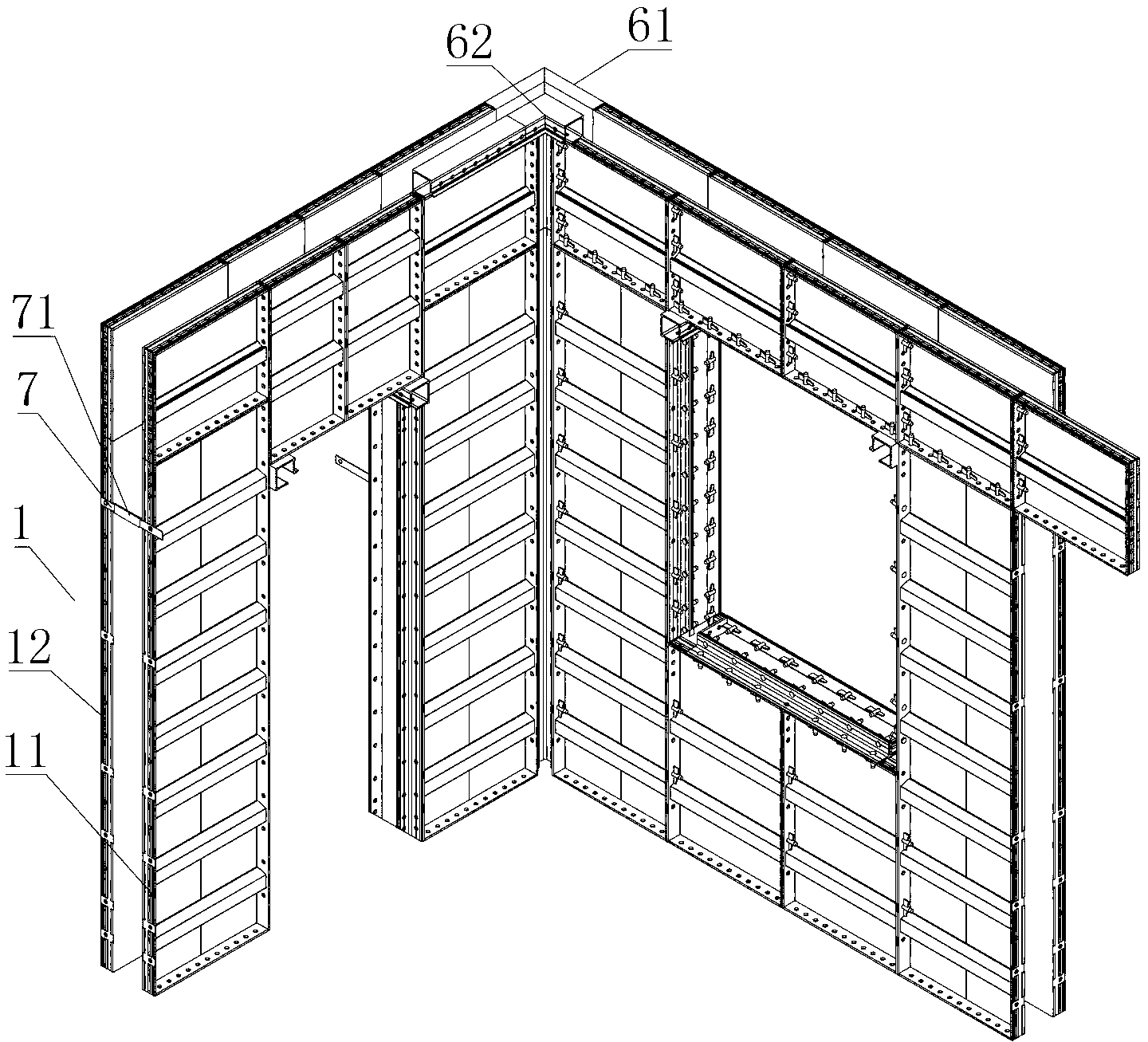

[0047] Described wall panel 1 comprises wall inner panel 11 and wall outer panel 12, and described wall inner panel 11 and wall outer panel 12 are provided with the pull tab 7 that is used to control wall inner and outer panel spacing, two of described pull tab 7 The end is provided with a mounting hole, and the pull tab 7 is fixed through the mounting hole when the wall panel 1 is fixed to the adjacent wall panel; Removal hole for easy removal.

[0048] The pull tab 7 is provided with a rubber sleeve 71 for easy disassembly of the pull tab 7. The length of the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com