Segment thickness coded bar code nanorod and preparation method thereof

A nanorod and barcode technology, applied in the field of nano-coded materials, can solve the problems of limited coding capacity and achieve the effects of increased coding capacity, uneven thickness, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of barcode nanorods with segment thickness coding, in the process of constructing multi-segment nanorods, when depositing a layer of polymer film, the substrate is controlled to incline at a certain angle relative to the horizontal plane, and the angle of inclination of the substrate is not all 0°;

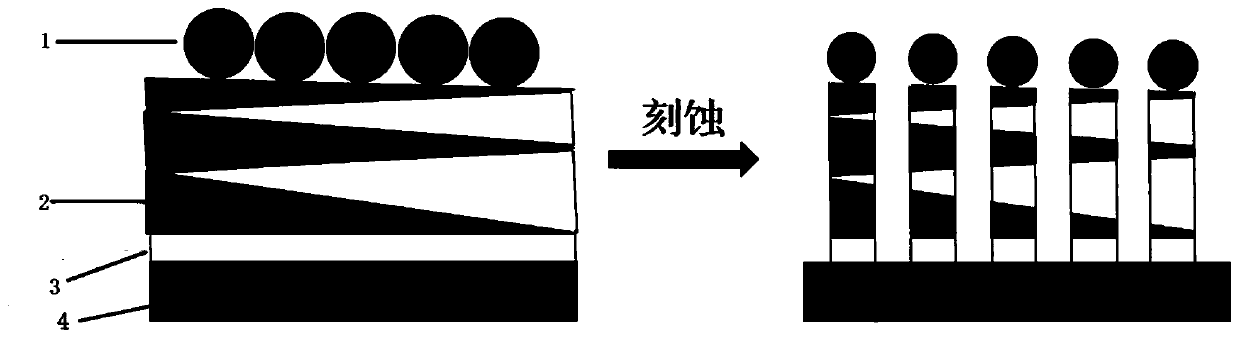

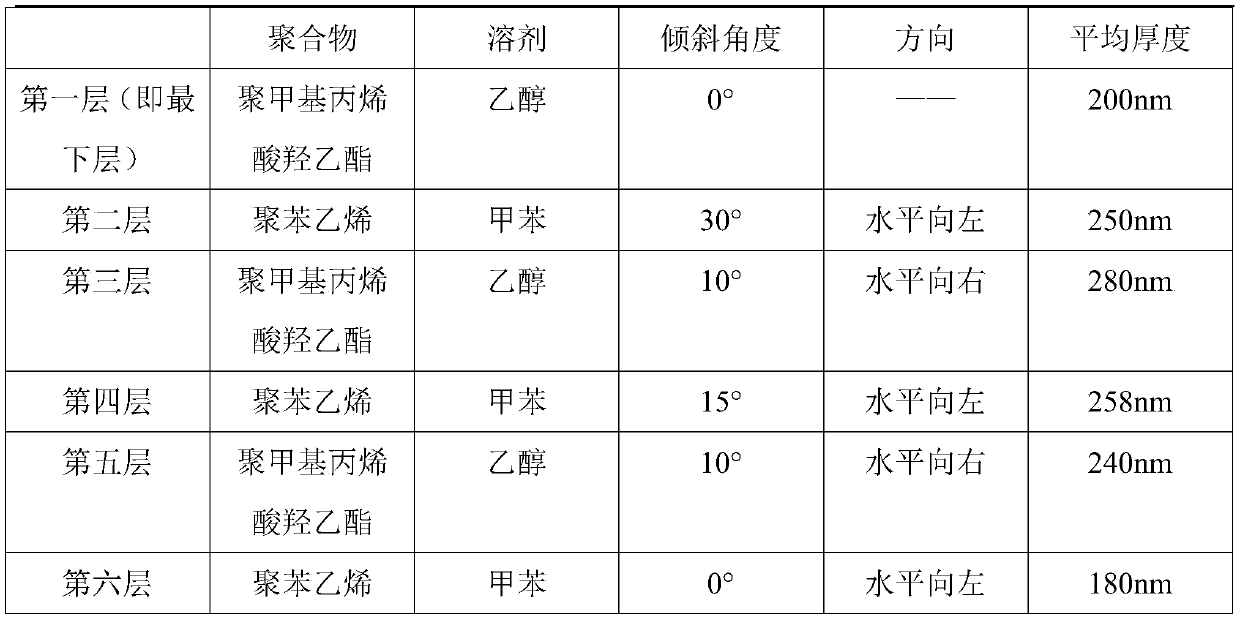

[0028] Multi-segment nanorods are constructed by colloidal crystal etching method, and the schematic diagram of the construction is shown in figure 1 As shown, the specific process is as follows: firstly, the solution of polymer b 3 and the solution of polymer a 2 are alternately deposited on the surface of the same substrate 4 (the substrate is a silicon substrate) to form a film by spin coating method, and then assembled on the surface of the six-layer polymer film Silica microspheres 1, then the closely packed silica microspheres are etched into non-close packed arrays by plasma etching technology, and finally the etched silica microspheres (average...

Embodiment 2

[0031] The preparation method of barcode nanorods with segment thickness coding, in the process of constructing multi-segment nanorods, when depositing a layer of polymer film, the substrate is controlled to incline at a certain angle relative to the horizontal plane, and the angle of inclination of the substrate is not all 0°;

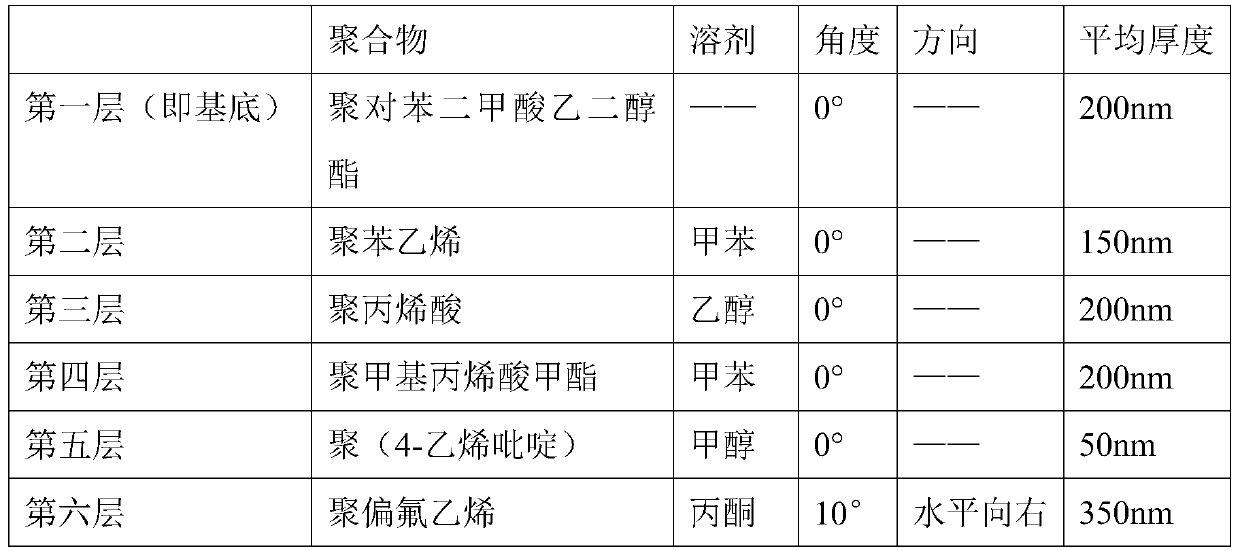

[0032] Multi-segment nanorods are constructed by colloidal crystal etching method. The construction process is as follows: firstly, different polymer solutions are sequentially deposited on the surface of the same substrate (the substrate is a silicon substrate) to form films by spin coating. , control the substrate to tilt at a certain angle relative to the horizontal plane, then assemble silica microspheres (average diameter of 500nm) on the surface of the three-layer polymer film, and then etch the closely packed silica microspheres using plasma etching technology into a non-tightly packed array, and finally use the etched silica microspheres as a m...

Embodiment 3

[0035] In the preparation method of barcode nanorods with segmental thickness coding, in the process of constructing multi-segmented nanorods, when depositing a layer of polymer film, the substrate is controlled to incline at a certain angle relative to the horizontal plane, and the angle of inclination of the substrate is not all 0°;

[0036]The multi-segment nanorods are constructed by colloidal crystal etching method. The construction process is as follows: firstly, different polymer solutions are sequentially deposited on the surface of the same substrate (the substrate is a silica substrate) to form films by spin coating, and each layer of polymer deposited When the film is formed, the substrate is tilted at a certain angle relative to the horizontal plane, and then silica microspheres are assembled on the surface of the three-layer polymer film, and then the closely packed silica microspheres are etched into a non-close packing by plasma etching technology. Finally, use t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com