Method and device of measuring material thermal shock property

A technology of measuring device and heating device, applied in the direction of measuring device, analytical material, instrument, etc., can solve problems such as damage, and achieve the effect of adding thermal insulation shield and stable and reliable measurement environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

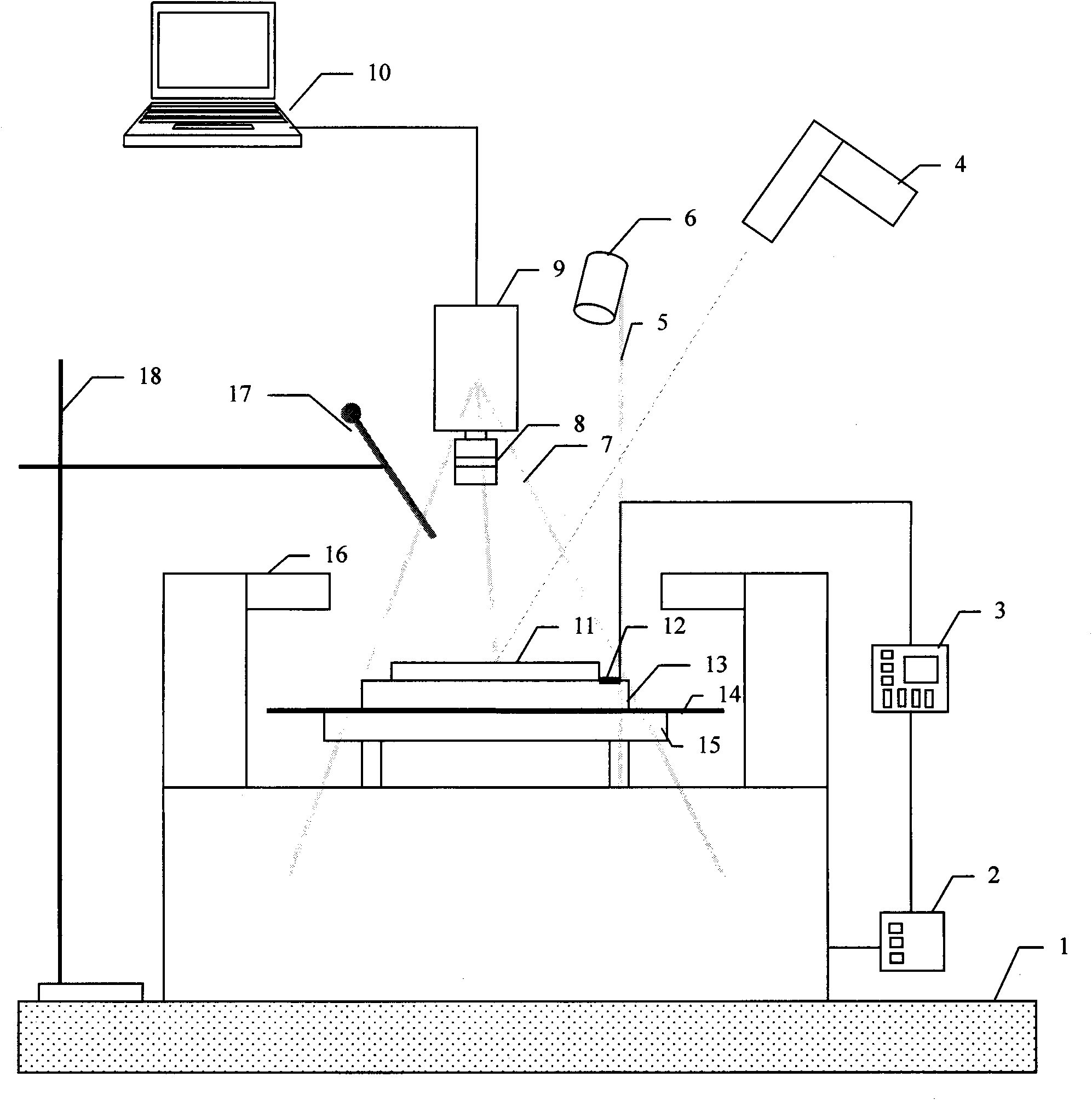

Method used

Image

Examples

Embodiment

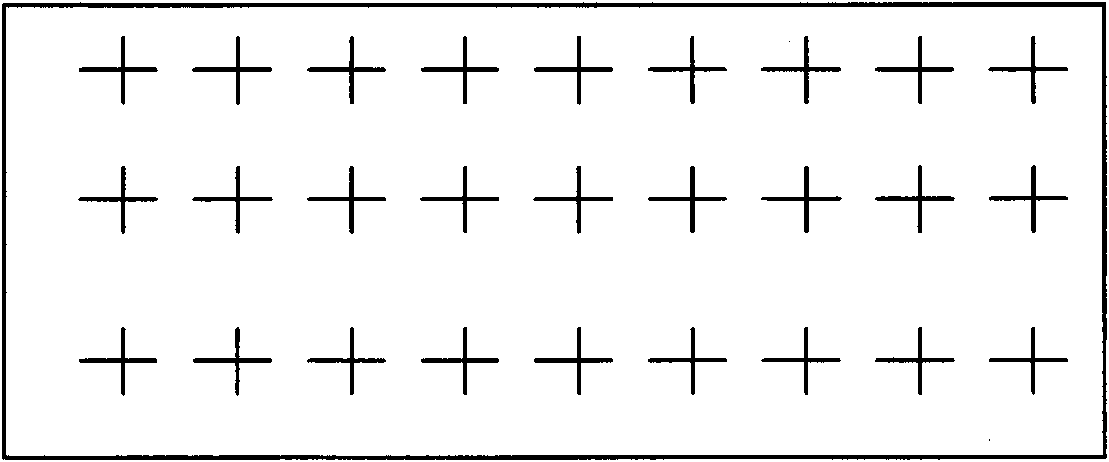

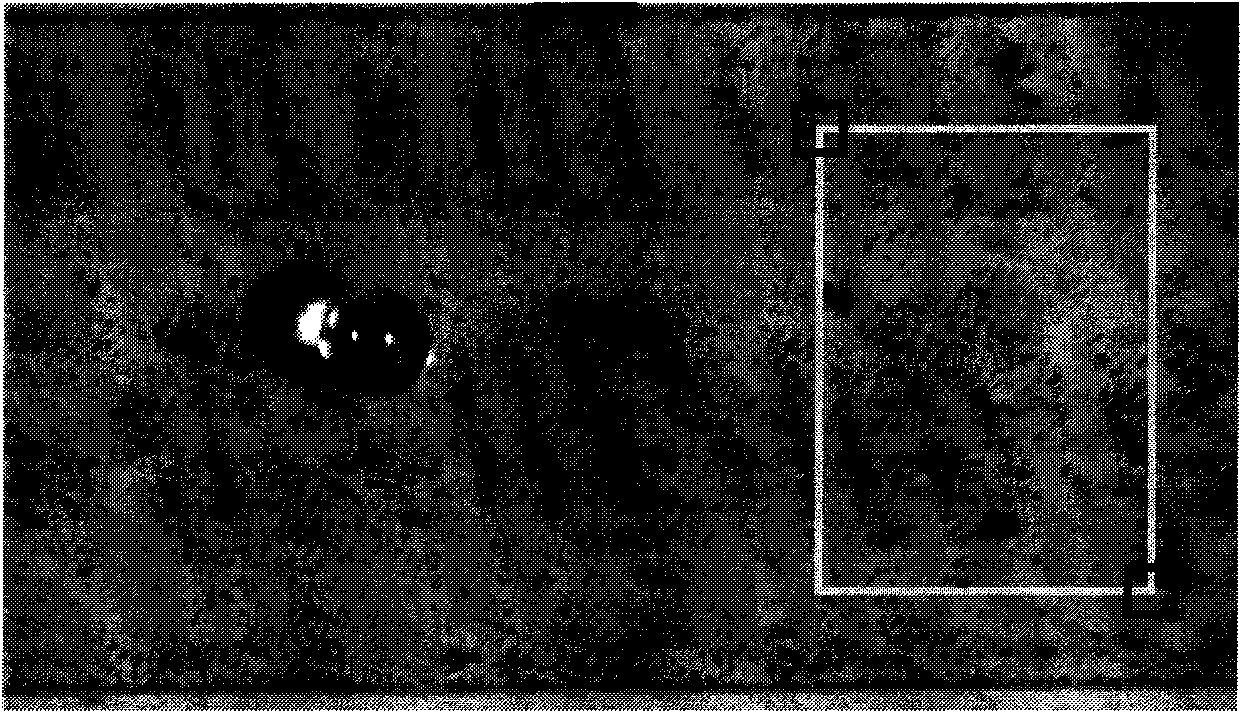

[0049] Example: The following is an experimental study conducted by us to illustrate a method for measuring the thermal shock behavior of materials and the use process of the device. Material: Ordinary glass slide, we conduct the test in an environment of about 300°C, and the speckle is made by spraying paint. As shown in the figure below, the precise temperature of the glass slide measured by the infrared thermometer when the water droplets started to act is 295°C. The shooting frequency of the high-speed camera is 4000 frames per second. We calculated the displacement changes in the x and y directions in the box area shown in the figure after the action of water droplets for 5.75 milliseconds (the displacement in the figure is in units of pixels, 0.125mm / pixels) .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com