Special auxiliary device for continuous measurement of molten iron temperature and molten iron temperature continuous measurement system

A technology of molten iron temperature and auxiliary device, which is applied in the direction of measuring device, optical radiation measurement, radiation pyrometry, etc. Error, the effect of protecting the window clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to be able to understand the technical content of the present invention more clearly, the following embodiments are specifically described in detail.

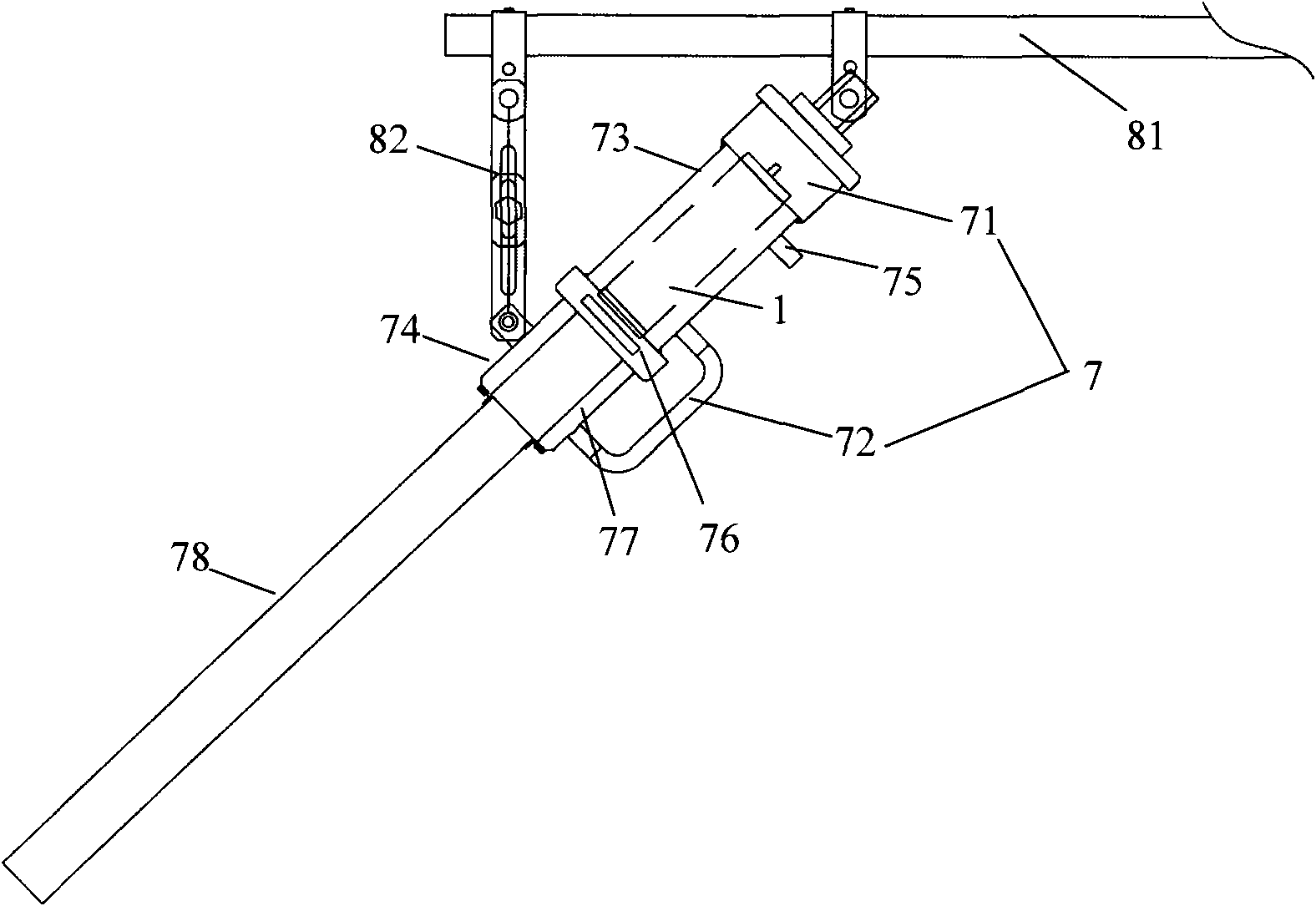

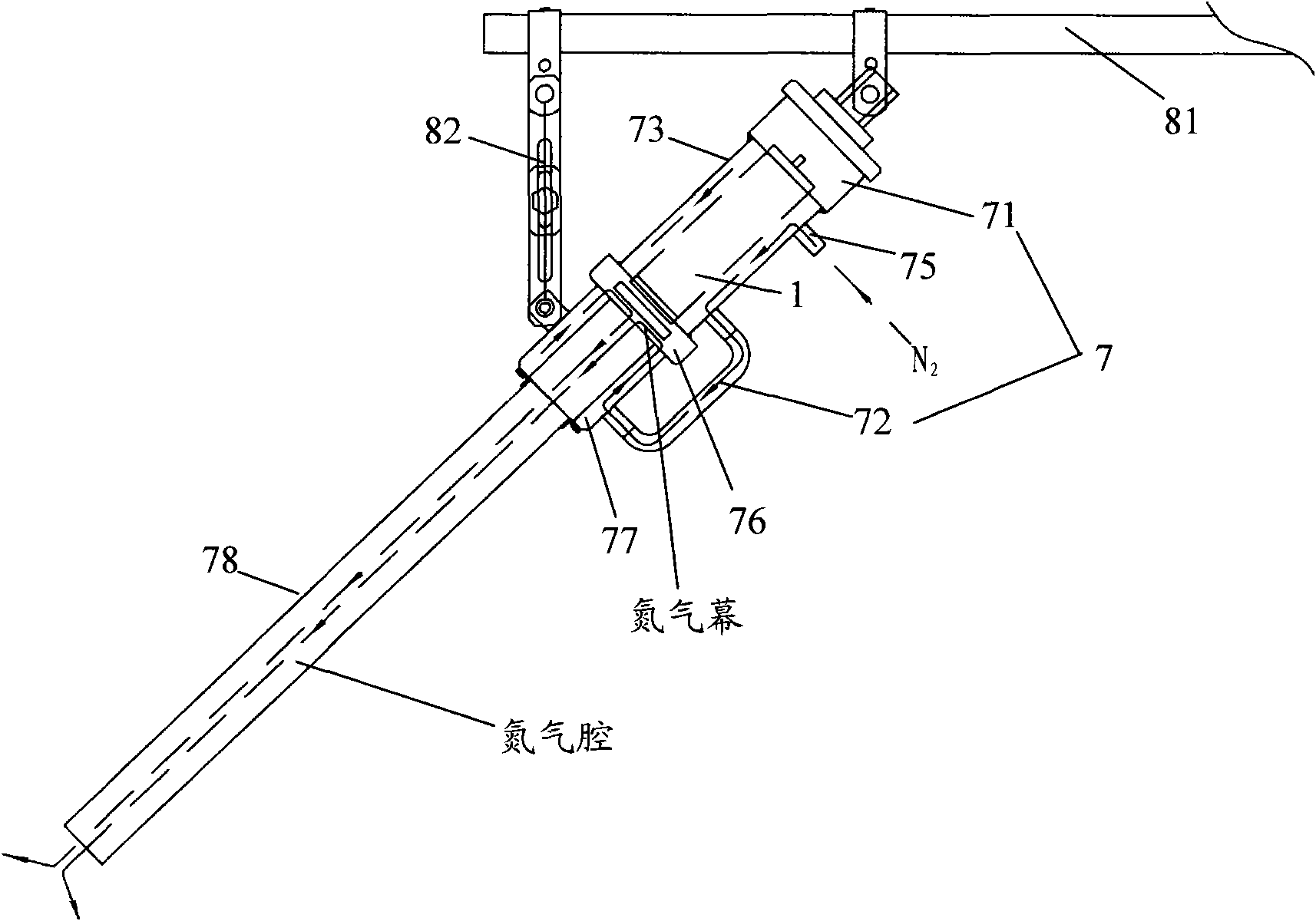

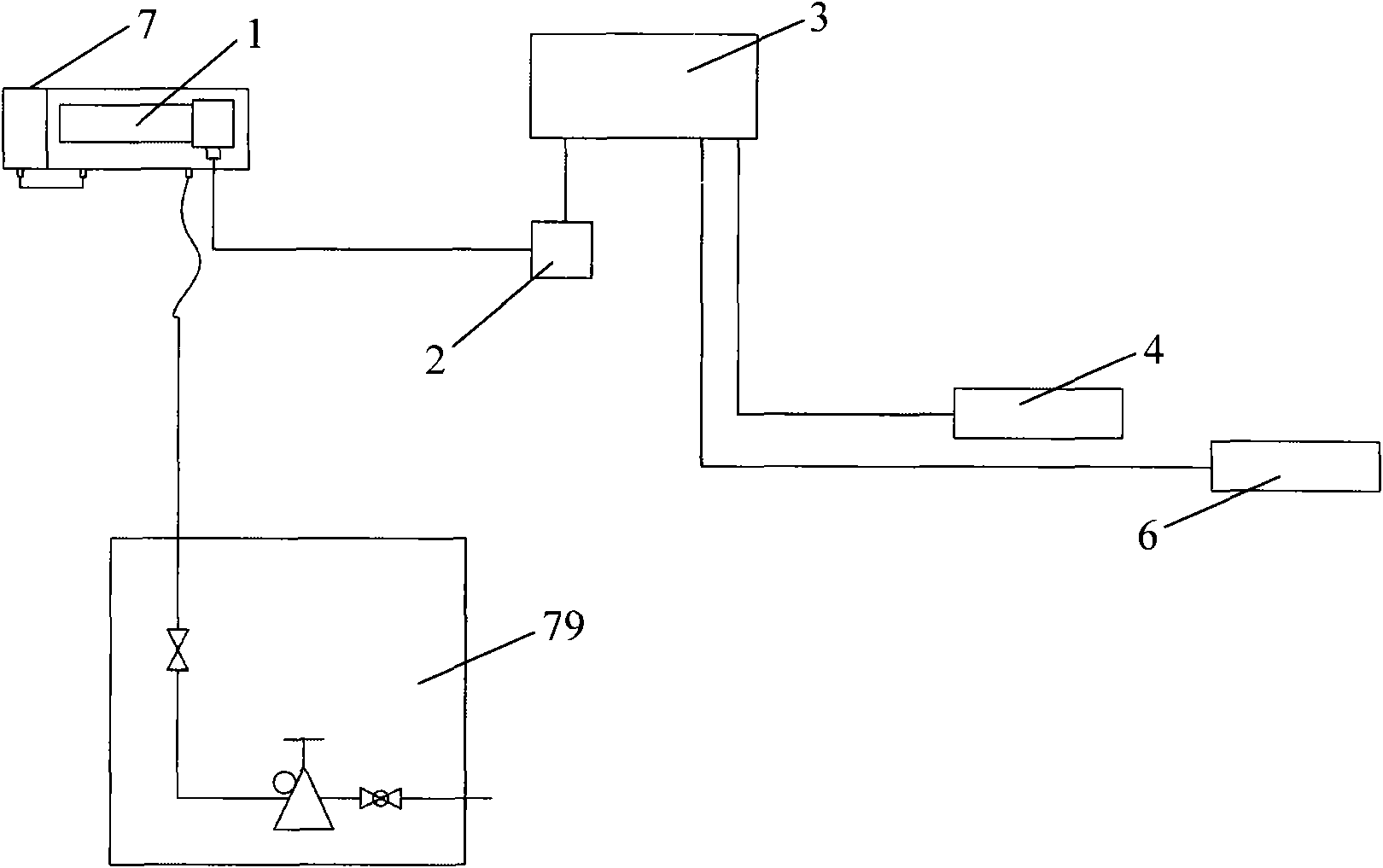

[0032] See Figure 1-Figure 2 As shown, the special auxiliary device for continuous measurement of molten iron temperature of the present invention includes an air cooling jacket 7. The air cooling jacket 7 includes a main pipe 71 and a secondary pipe 72, and the main pipe 71 includes a first end 73 and a second end. 74. The first end 73 has an air inlet 75, the auxiliary pipe 72 communicates the first end 73 and the second end 74, and the main pipe 71 has an infrared radiation thermometer installation position 76, The infrared radiation thermometer installation position 76 is located between the first end 73 and the second end 74. After the infrared radiation thermometer 1 is installed in the infrared radiation thermometer installation position 76 in the main pipe 71, the first end 73 and the second end 74 of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com