Infra-red heating tinsel plate pneumatic forming method and apparatus

An infrared heating and metal foil technology, applied in the field of metal foil plate microforming and infrared heating metal foil plate air pressure forming, can solve the problems of uneven forming, complex process, poor forming ability, etc., to avoid stress concentration and simplify the forming process , to ensure the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

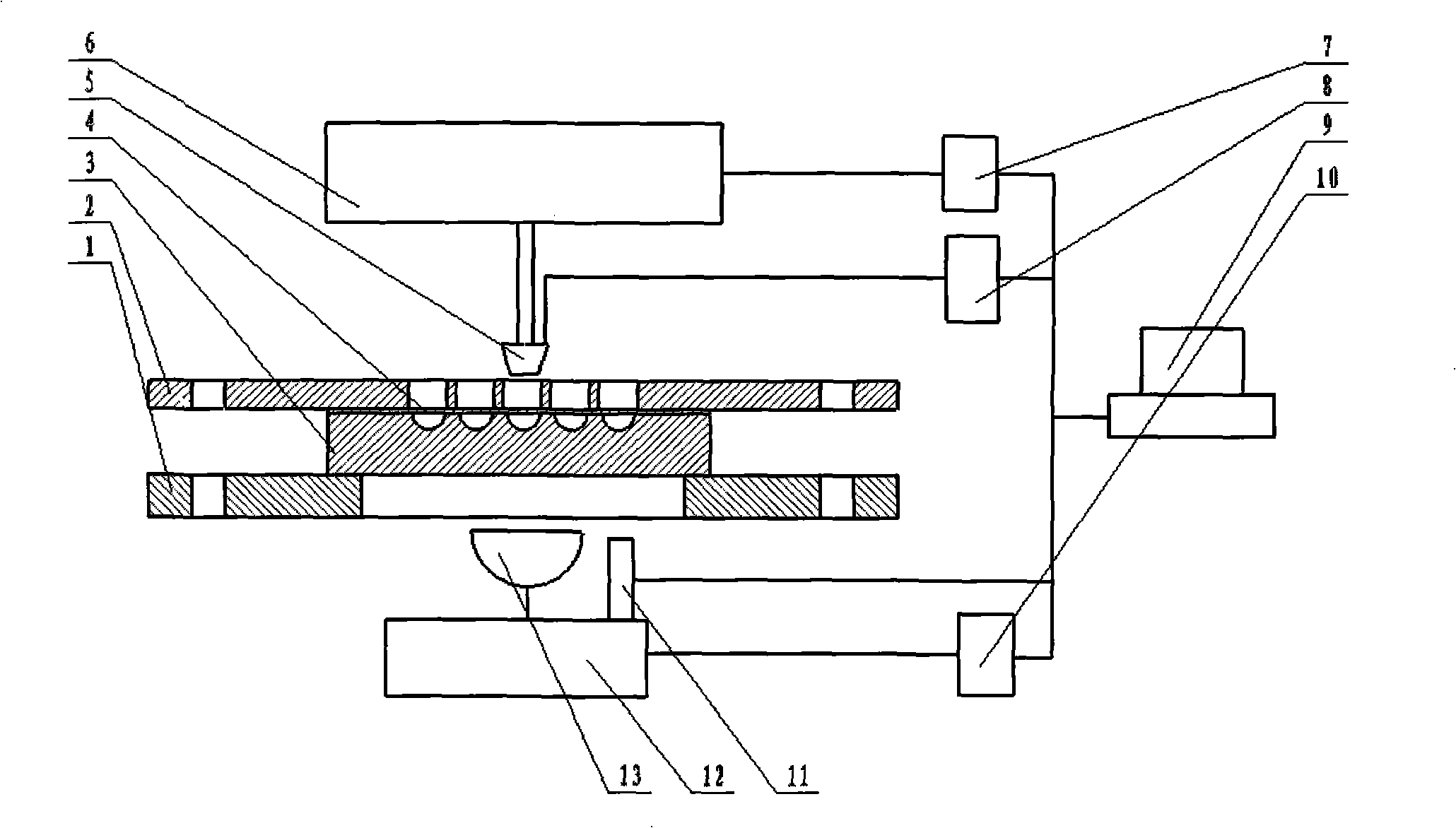

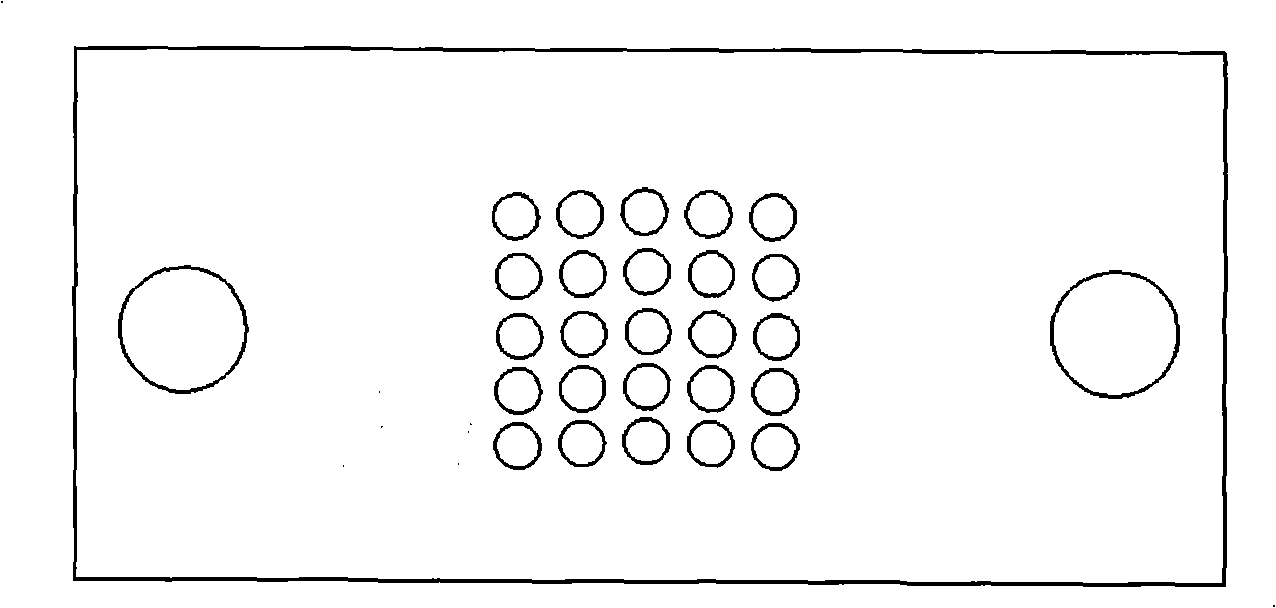

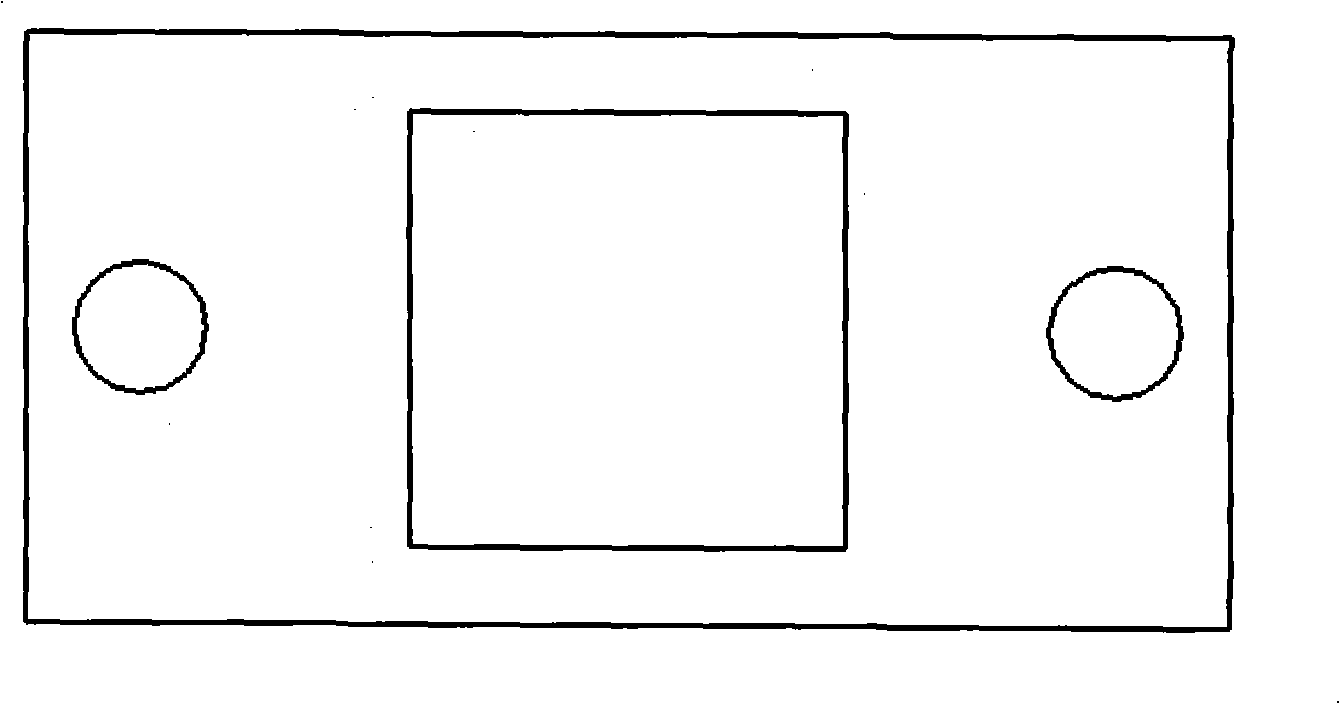

[0020] A device for air pressure forming of an infrared heating metal foil plate proposed by the present invention is as follows: figure 1 As shown, the entire forming device consists of 12 parts. The three-dimensional mobile platform controller 7 is connected with the three-dimensional mobile platform 6 through the data line, and the air pressure nozzle 5 is installed below the three-dimensional mobile platform 6, and the air pressure nozzle 5 is connected with the air compressor 8, and the upper platen 2, the miniature The metal foil plate 4 to be processed is placed between the mold 3 and the bottom plate 1, the upper platen 2 and the micro mold 3; the infrared focused heating instrument 13 is installed under the bottom plate 1, and the infrared focused heating instrument 13 is installed on the three-dimensional workbench 12. Infrared thermometer 11 is also installed on the workbench 12, three-dimensional workbench 12 links to each other with driver 10, said three-dimension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com