Testing device for testing low-temperature adsorption performance of gas

A test device and adsorption performance technology, which is applied in the field of gas adsorption performance testing, can solve the problems of waste of raw materials and complicated experimental operations, and achieve the effects of accurate and controllable temperature, simple operation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

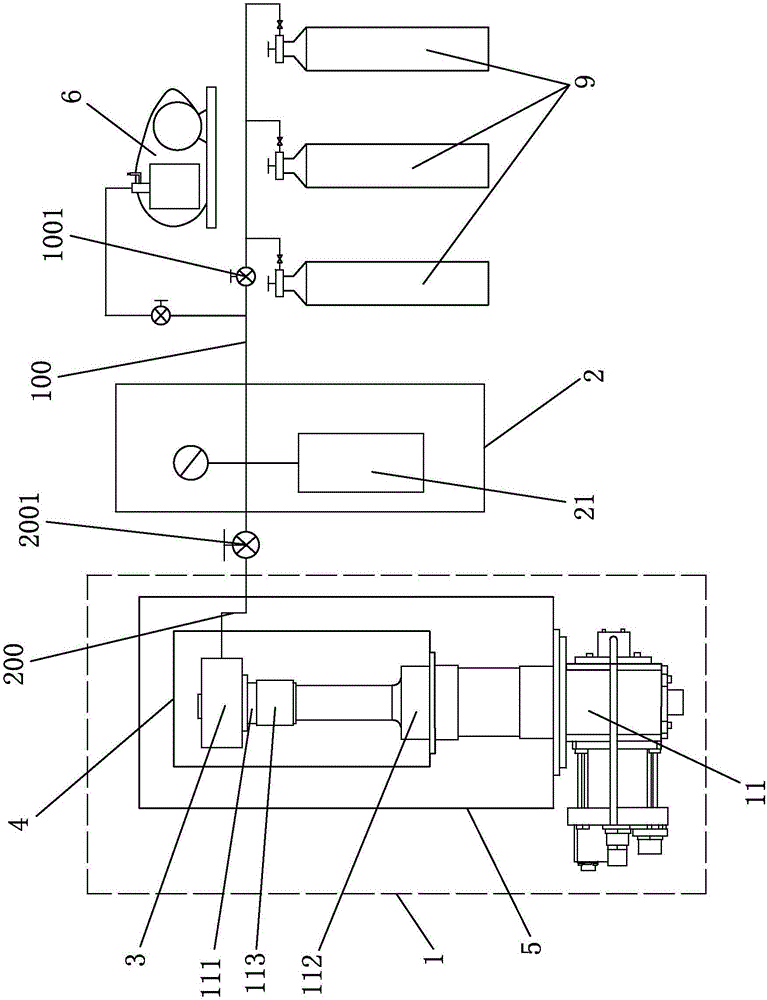

[0026] Such as figure 1 As shown, this embodiment provides a test device for testing the low-temperature adsorption performance of a single-component gas, and the test device includes a low-temperature device 1, which is used to test the adsorption properties between the test gas and the test sample. The gas adsorption instrument 2 for testing and the gas intake pipeline 100 connected to the adsorption instrument reference chamber 21 in the gas adsorption instrument 2 for testing gas input; , and the intake pipeline 100 is provided with a first valve 1001 .

[0027] The cryogenic device 1 includes a refrigerator 11, a sample cavity 3 for placing samples for testing on the secondary cold head 111 of the refrigerator 11, a cover set outside the secondary cold head 111 of the refrigerator 11 and the sample cavity 3 The shielding cover 4 and the vacuum cover 5 that are arranged outside the shielding cover 4 to make the first-stage cold head 112 of the refrigerator 11, the second-...

Embodiment 2

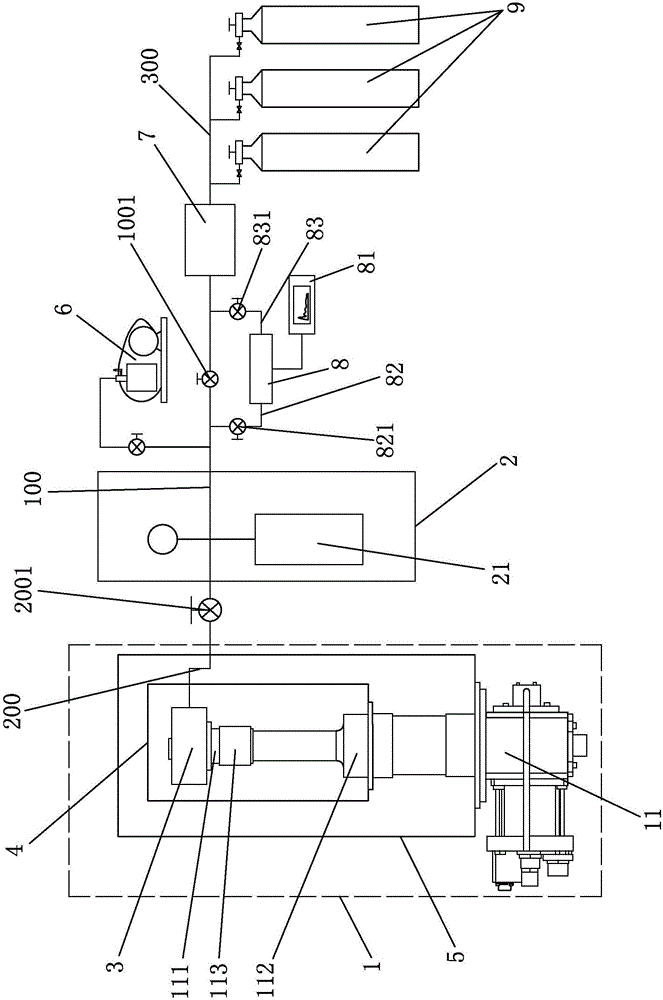

[0036] like figure 2 As shown, this embodiment provides a test device for testing gas low-temperature adsorption performance for multi-component gases. The gas adsorption instrument 2 for testing, the intake pipeline 100 connected to the adsorption instrument reference cavity 21 in the gas adsorption instrument 2 for testing gas input, and the multiple groups connected to the intake end of the intake pipeline 100 The sub-gas reference chamber 7, the multi-component gas input pipeline 300 connected to the multi-component gas reference chamber 7, the sampling gas reference chamber 8 arranged in parallel with the intake pipeline 100 and the sampling gas reference chamber 8 The gas chromatograph 81 that chamber 8 is connected; The gas storage tank 9 of a plurality of different components is connected with the gas storage tank 9 of described multi-component gas input pipeline 300 intake end, and described sampling gas reference chamber 8 passes first branch pipeline 82 and The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com