Built-in high-temperature wireless pressure sensor

A pressure sensor and sensor technology, which is applied in the measurement of fluid pressure using capacitance change, and the measurement of force by measuring the frequency change of a stressed vibration element, can solve the problems of difficult application temperature exceeding 600 ℃ and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

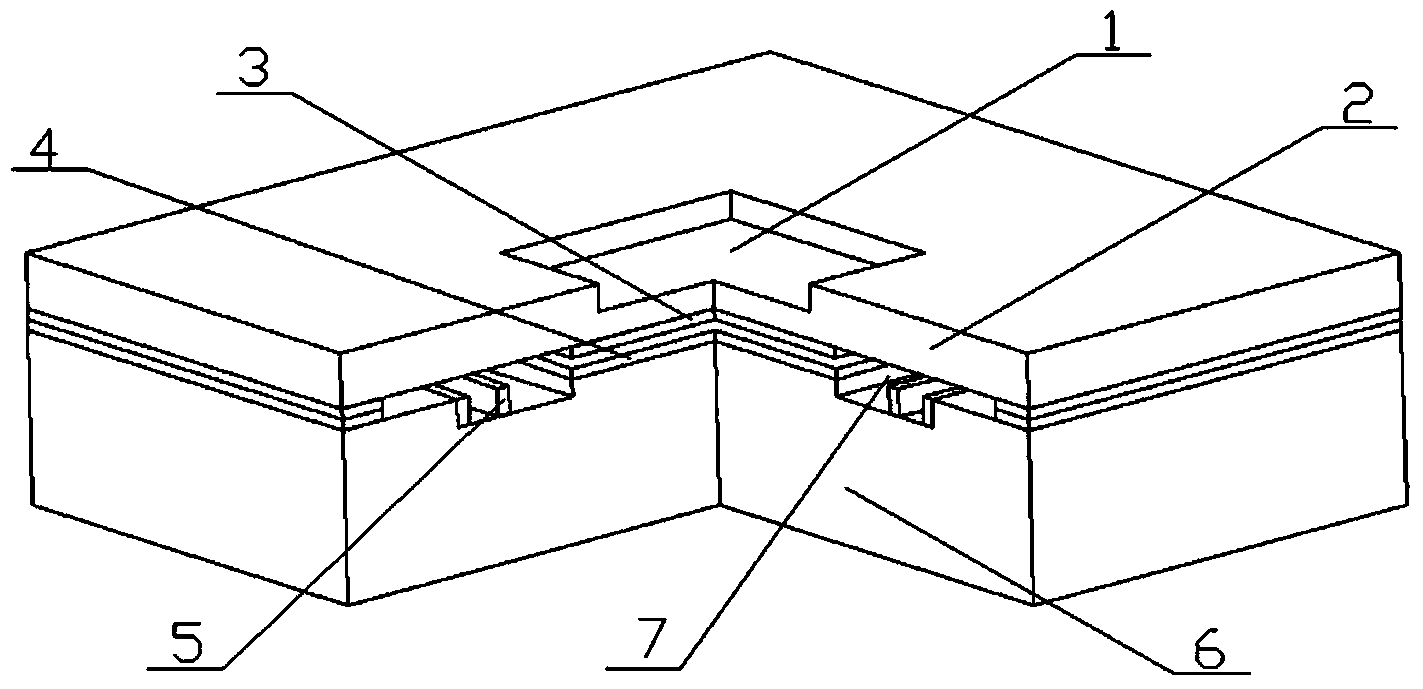

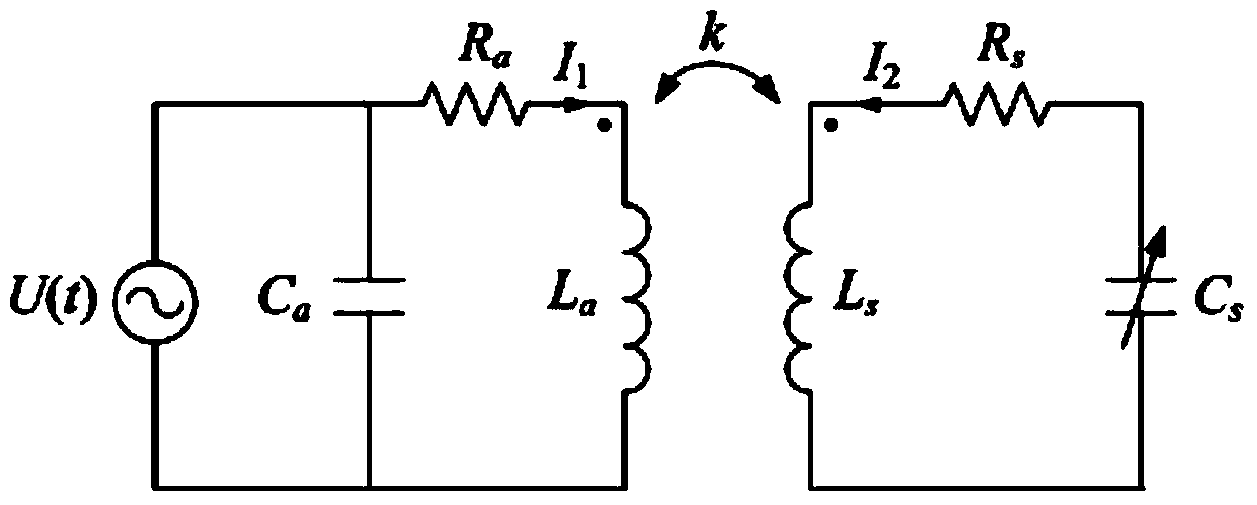

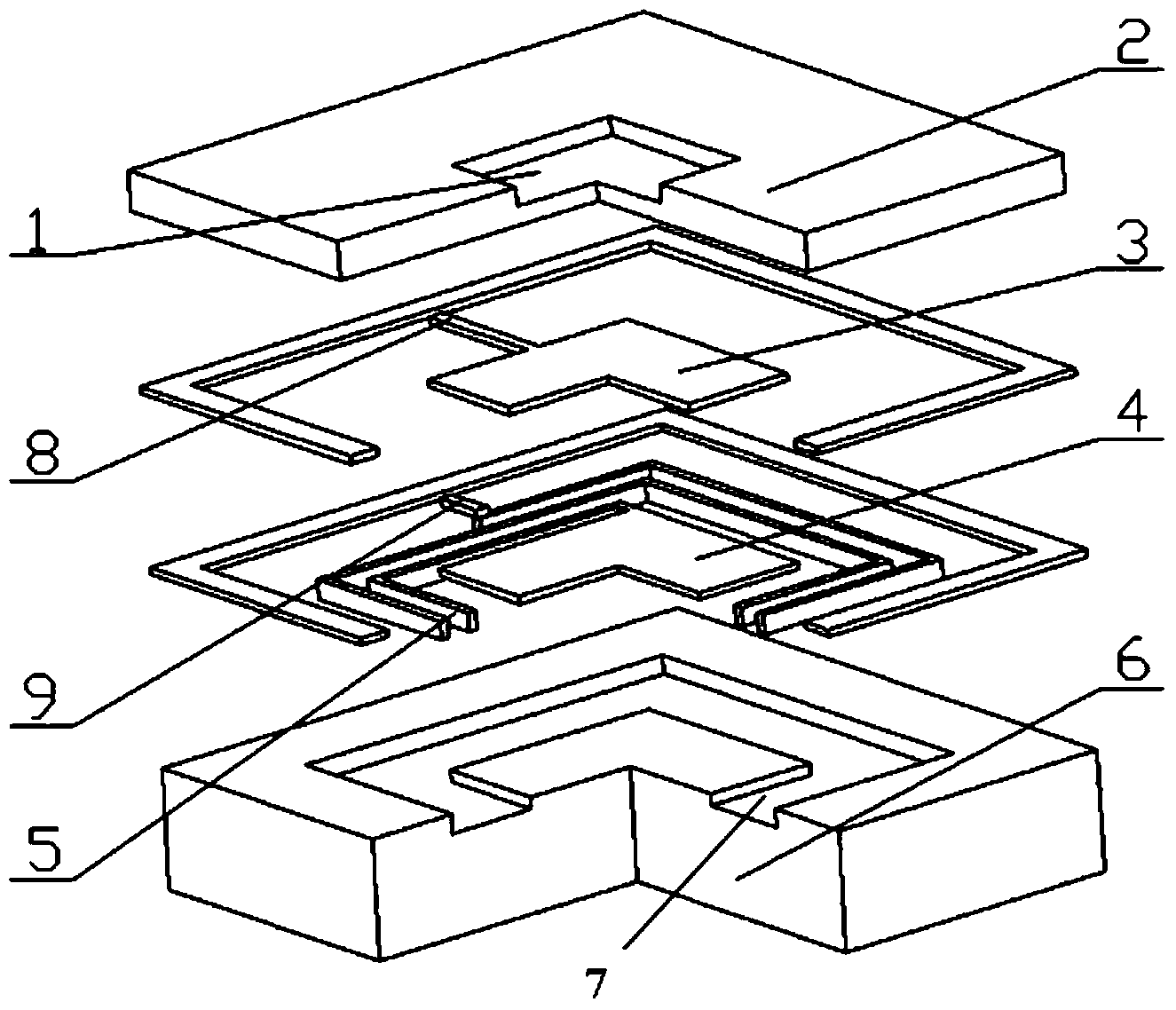

[0022] see Figure 1~4 , the embodiment of the present invention is provided with a pressure sensitive membrane 1 , a sensor upper cover plate 2 , a capacitor upper plate 3 , a capacitor lower plate 4 , an inductance coil 5 , a sensor base 6 and a pressure reference cavity 7 . The sensor upper cover plate 2 is made of SiC sheet, a square groove is opened on the sensor upper cover plate to form a pressure sensitive film 1, and a capacitor upper plate 3 is made on the back of the sensor upper cover plate 2; the sensor base 6 Made of SiC sheet, the sensor base 6 is provided with a return-shaped groove, the capacitor lower plate 4 and the inductance coil 5 are made on the sensor base 6, and the upper surface of the capacitor lower plate 4 is flush with the upper surface of the inductance coil 5 , and the inductance coil 5 is made in the return-shaped groove to increase the thickness of the inductance coil 5; the capacitor upper plate 3, the capacitor lower plate 4 and the inductan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com