Planar oxygen sensor and method for producing same

An oxygen sensor and oxygen sensing technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of unstable output voltage signal of oxygen sensor and low yield rate of oxygen sensor, and achieve stable air pressure, not easy to deform, and voltage signal stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

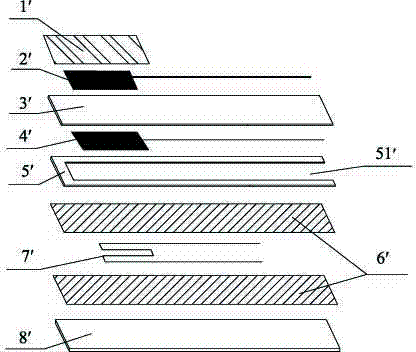

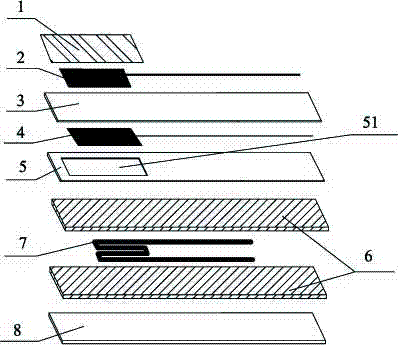

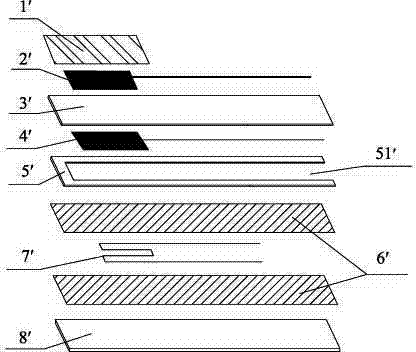

[0017] The present invention also provides a preparation method of a chip oxygen sensor, which comprises firstly cutting a through hole on the reference gas layer, then stacking the heating layer, the reference gas layer and the sensing layer in order from bottom to top, hot pressing and sintering to form a closed reference cavity at the through hole to obtain the chip oxygen sensor.

[0018] Specifically, the following steps are included:

[0019] 1) Take a heater substrate, print insulating layer paste, electrode paste, and insulating layer paste on the heater substrate in sequence, and dry to form an insulating layer on the heater substrate to obtain a heating layer;

[0020] 2) Print electrode paste on both sides of the zirconia sensitive substrate and dry to form electrodes on both sides of the zirconia sensitive substrate; then print a porous protective layer on one side of the electrode and dry to form a porous protective layer on the surface the sensing layer;

[002...

Embodiment 1

[0030] (1) Raw material preparation:

[0031] Insulating layer slurry: 75 parts by weight of aluminum oxide, 3 parts by weight of silicon oxide, 5 parts by weight of magnesium oxide, 15 parts by weight of terpineol, and 2 parts by weight of ethyl cellulose.

[0032] Electrode slurry: 81 parts by weight of Pt powder, 2 parts by weight of alumina, 2 parts by weight of zirconia, 10 parts by weight of terpineol, and 5 parts by weight of ethyl cellulose.

[0033] Porous protective layer slurry: 54 parts by weight of magnesium aluminum spinel, 30 parts by weight of alumina, 8 parts by weight of terpineol, 2 parts by weight of ethyl cellulose, and 6 parts by weight of a pore-forming agent.

[0034] (2) Print insulating layer slurry, electrode slurry, and insulating layer slurry on the zirconia cast sheet in sequence, and dry to obtain a heating layer.

[0035] (3) Cut a through hole on the zirconia cast sheet, the area of the through hole accounts for 8% of the total area of the...

Embodiment 2

[0039] The chip type oxygen sensor chip S2 of this embodiment was prepared by the same method as that of Example 1, the difference being that:

[0040] In step (3), the area of the through hole accounts for 5% of the total area of the reference gas layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com