Method and tooling for controlling deformation of nickel-based ageing-strengthening high-temperature alloy casing welding assembly

An aging-strengthening, high-temperature alloy technology, used in welding accessories, manufacturing tools, welding equipment, etc., can solve the problems of uncontrollable fatigue crack reliability and life requirements of gas turbines, eliminate welding residual stress, save money, and avoid fatigue. crack effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

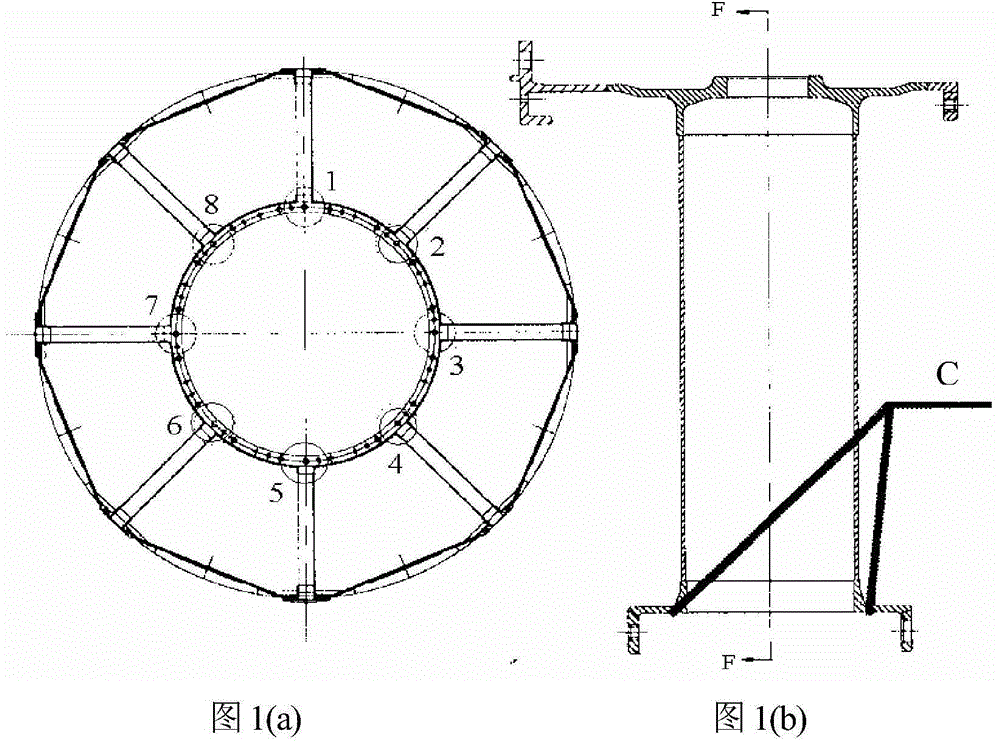

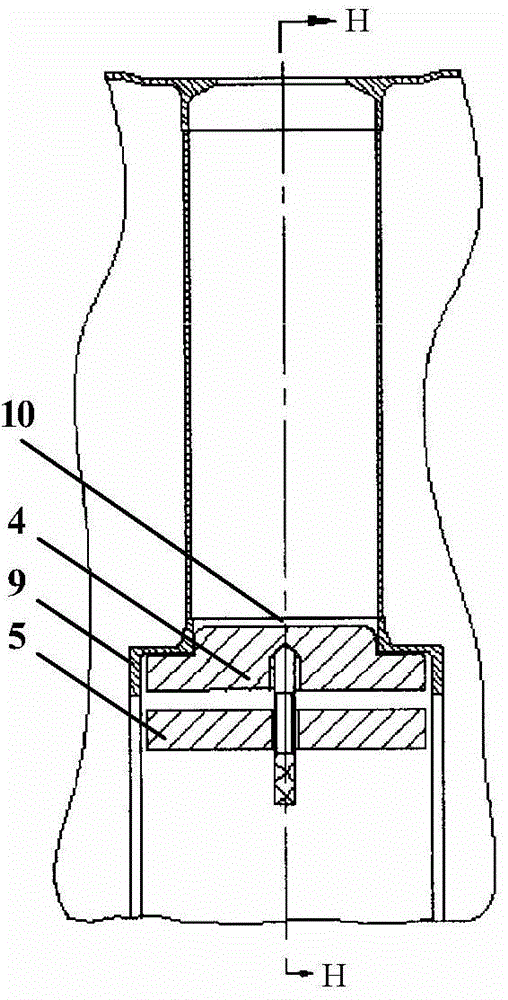

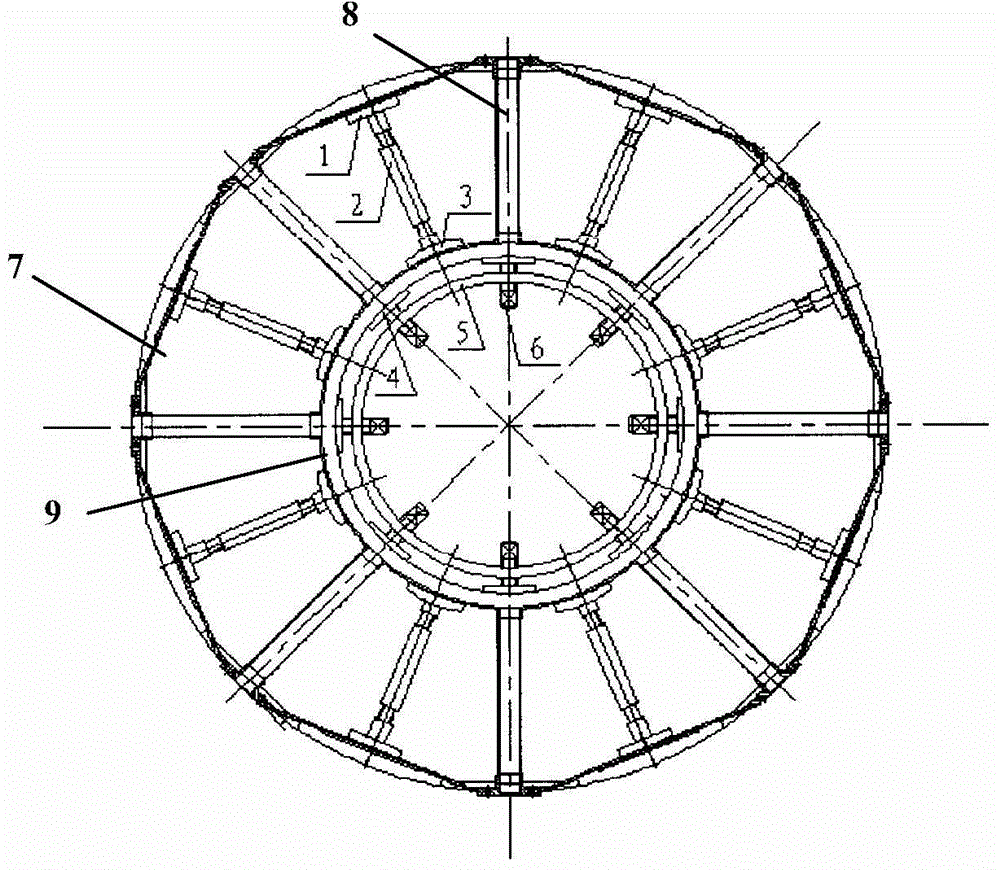

[0034] The present invention analyzes the cause of the crack failure of the rear casing of a certain gas turbine, and the rear casing has residual stress during the combined welding and mechanical processing process, and fatigue cracks are generated during work. In order to completely eliminate the residual stress after welding, add solution treatment to remove the stress, and design special tooling, use rigid limit to control the amount of welding deformation, and at the same time, bring special process equipment for stress relief treatment to more accurately control the amount of welding deformation. Within the required range, the problem of fatigue cracks that cannot be controlled by traditional welding process methods and process equipment is solved.

[0035] The working principle of the process method and process equipment of the present invention is as follows:

[0036] Use material rigid limits with similar linear expansion coefficients to control welding deformation, adopt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com