Non-oriented silicon steel for drive motor of electric automobile and preparation method thereof

A technology for driving motors and electric vehicles. It is applied in the field of non-oriented silicon steel manufacturing. It can solve the problems of poor magnetic properties and achieve excellent magnetic properties, short soaking time, and excellent magnetic levels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the examples to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

[0041] The performance of the non-oriented silicon steel for electric vehicle drive motor prepared by optimizing the chemical composition will be further described below in conjunction with specific examples.

[0042] The chemical composition of the slab is shown in Table 1

[0043] Table 1 The chemical composition of the slab is shown in Table 1 (wt,%)

[0044]

[0045]

[0046]

[0047]

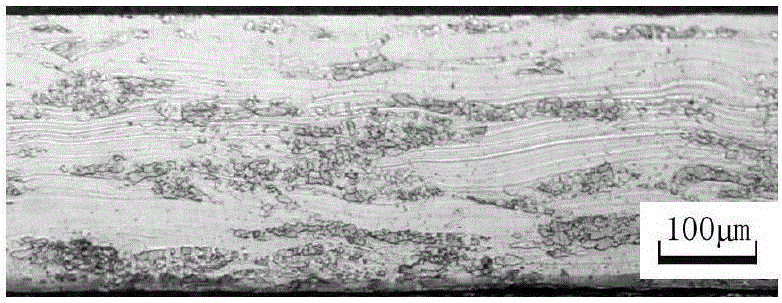

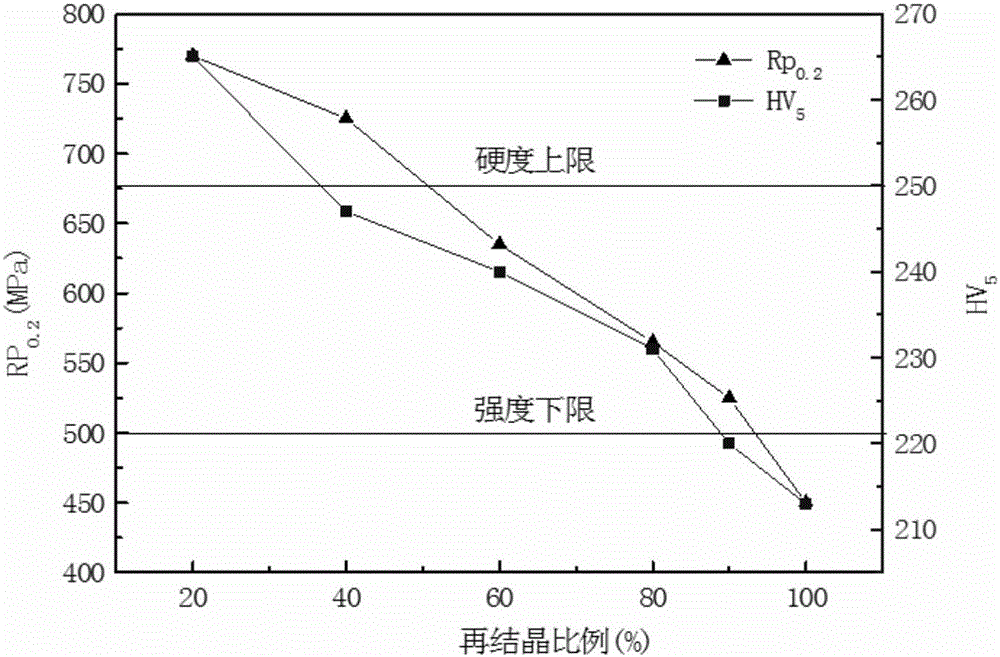

[0048] The rest is Fe (iron) and unavoidable impurities. Put the cast slab with a thickness of 200mm into the heating furnace for soaking, and hot-roll it into a hot-rolled coil with a thickness of 2.0mm. After the soaking temperature is 900°C, the soaking time is 40-180s, and the acid percentage concentration is 5%. Pickling at 80°C, rinsing at 45°C, cold rolling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com