Metal-matrix diamond composite material and 3D (three dimensional) printing manufacturing method of parts of metal based diamond composite material

A composite material, 3D printing technology, applied in the field of manufacturing, can solve the problems of low work efficiency, high power consumption, difficult loading, etc., to achieve stable and excellent mechanical properties, shorten the manufacturing cycle, and fast cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The embodiment of the present invention provides a metal-based diamond composite material, which is made of raw materials in the following volume ratio: 2% diamond, and the rest is metal powder;

[0031] The metal powder is spherical or nearly spherical, and the particle size of the metal powder is 15 μm to 65 μm. The grade of the diamond is in the SMD 30 type or above, the particle size of the diamond is 80 mesh to 100 mesh. The metal powder is a mixture of FMA-201 iron-nickel-cobalt pre-alloy powder and copper-tin pre-alloy powder.

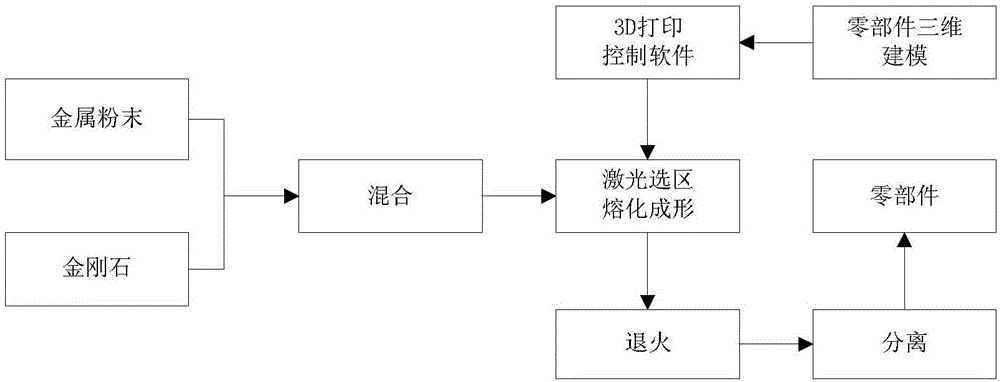

[0032] Please refer to figure 1 , a 3D printing manufacturing method of a metal-based diamond composite material and parts thereof, comprising the following steps:

[0033] (1) The metal powder and diamond are mixed evenly in argon by a ball mill according to the above volume ratio, which is conducive to improving the degree of dispersion of diamond in the metal powder in the subsequent forming process;

[0034] (2) Establish the three...

Embodiment 2

[0039] The embodiment of the present invention provides a metal-based diamond composite material, which is made of raw materials with the following volume ratio: diamond 16%, and the rest is metal powder;

[0040] The metal powder is spherical or nearly spherical, and the particle size of the metal powder is 20 μm to 65 μm. The grade of the diamond is in the SMD 30 type or above, the particle size of the diamond is 70 mesh to 80 mesh. The metal powder is a mixed powder of FMA-201 iron-nickel-cobalt pre-alloy powder and copper-tin pre-alloy powder.

[0041] Please refer to figure 1 , a 3D printing manufacturing method of a metal-based diamond composite material and parts thereof, comprising the following steps:

[0042] (1) The metal powder and diamond are mixed uniformly by a ball mill in argon according to the above volume ratio, which is conducive to improving the degree of dispersion of diamond in the metal powder during the subsequent forming process;

[0043] (2) Estab...

Embodiment 3

[0048] The embodiment of the present invention provides a metal-based diamond composite material, which is made of raw materials in the following volume ratio: diamond 30%, and the rest is metal powder;

[0049] The metal powder is spherical or nearly spherical, and the particle size of the metal powder is 20 μm to 65 μm. The grade of the diamond is in the SMD 30 type or above, the particle size of the diamond is 40 mesh to 50 mesh. The metal powder is a mixed powder of FMA-201 iron-cobalt-nickel pre-alloy powder and copper-tin pre-alloy powder.

[0050] Please refer to figure 1 , a 3D printing manufacturing method of a metal-based diamond composite material and parts thereof, comprising the following steps:

[0051] (1) The metal powder and the diamond are uniformly mixed by the ball mill in the argon gas according to the above-mentioned volume ratio, which is beneficial to improve the dispersion degree of the diamond in the metal powder during the subsequent forming proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com