Inductance element

A technology of inductive components and conductive metals, applied in the direction of inductance with magnetic core, transformer/inductor coil/winding/connection, etc. The effect of brazing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

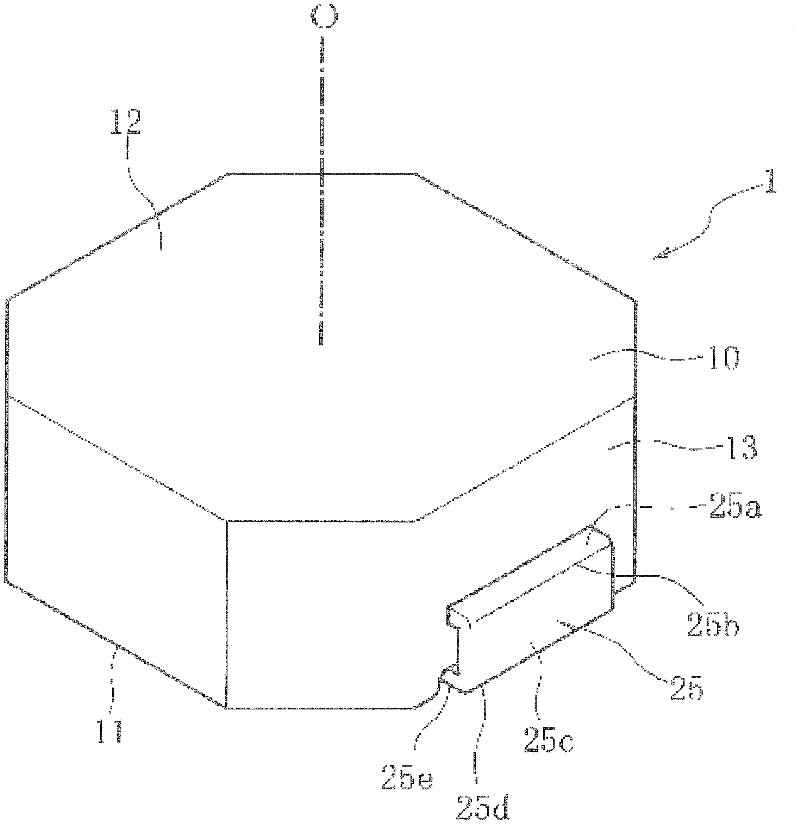

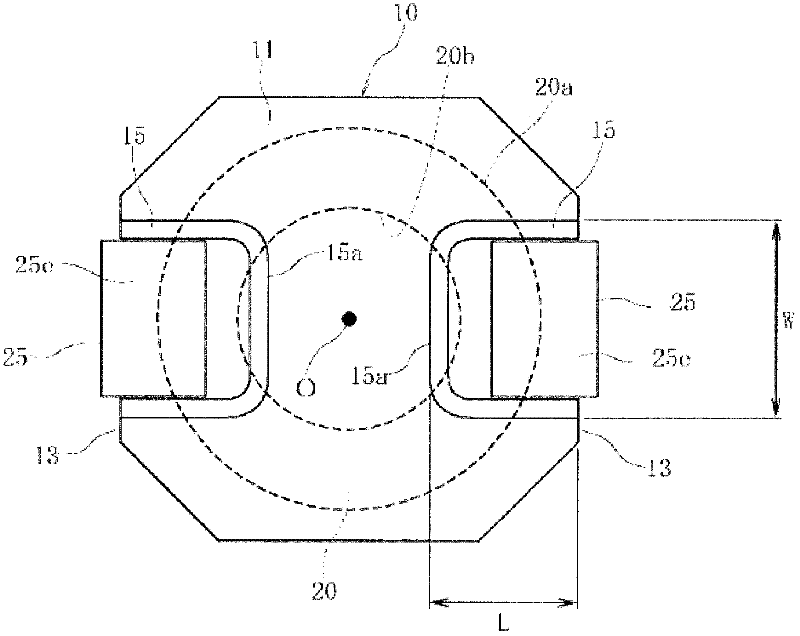

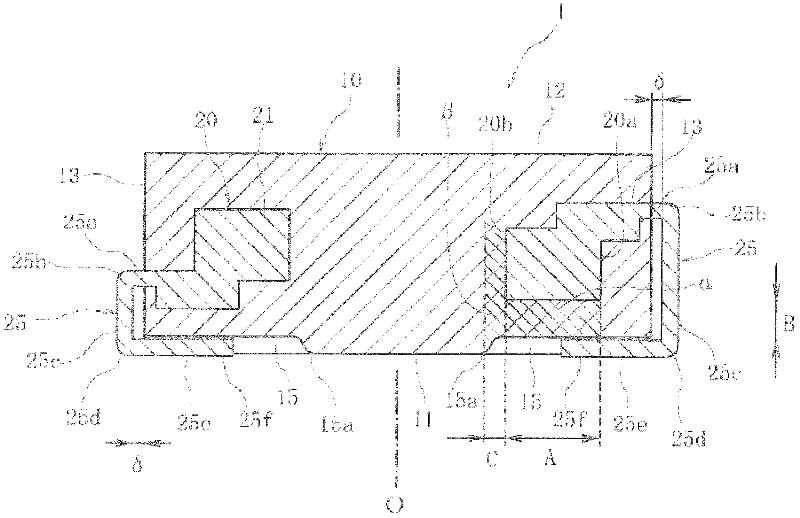

[0047] Figure 1 to Figure 3 In the illustrated inductance element 1 , a coil body 20 is embedded in a magnetic core 10 . A pair of terminal plates 25 , 25 are connected to the coil body 20 , and the terminal plates 25 , 25 extend to the outside of the magnetic core 10 .

[0048] The magnetic core 10 has a bottom surface 11 and an upper surface 12, and the bottom surface 11 and the upper surface 12 are parallel to each other. Such as figure 2 As shown, the shape of the magnetic core 10 viewed from the bottom surface 11 side is an octagon. The terminal boards 25 , 25 extend from the side surfaces 13 , 13 that are parallel to each other among the eight side surfaces. exist Figure 1 to Figure 3 In , a line extending perpendicular to the bottom surface 11 and the upper surface 12 of the magnetic core 10 and passing through the center of the octagon is represented by a centerline O.

[0049] Furthermore, the planar shape of the magnetic core 10 may be a square, a rectangle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com