Silicone adhesive for semiconductor element

a silicon adhesive and semiconductor technology, applied in the direction of non-macromolecular adhesive additives, transportation and packaging, layered products, etc., can solve the problems of deterioration in light extraction efficiency, deterioration in light reflection efficiency, and reduction in brightness, so as to achieve effective reflection of light emitted, improve light extraction efficiency, and high degree of concealment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

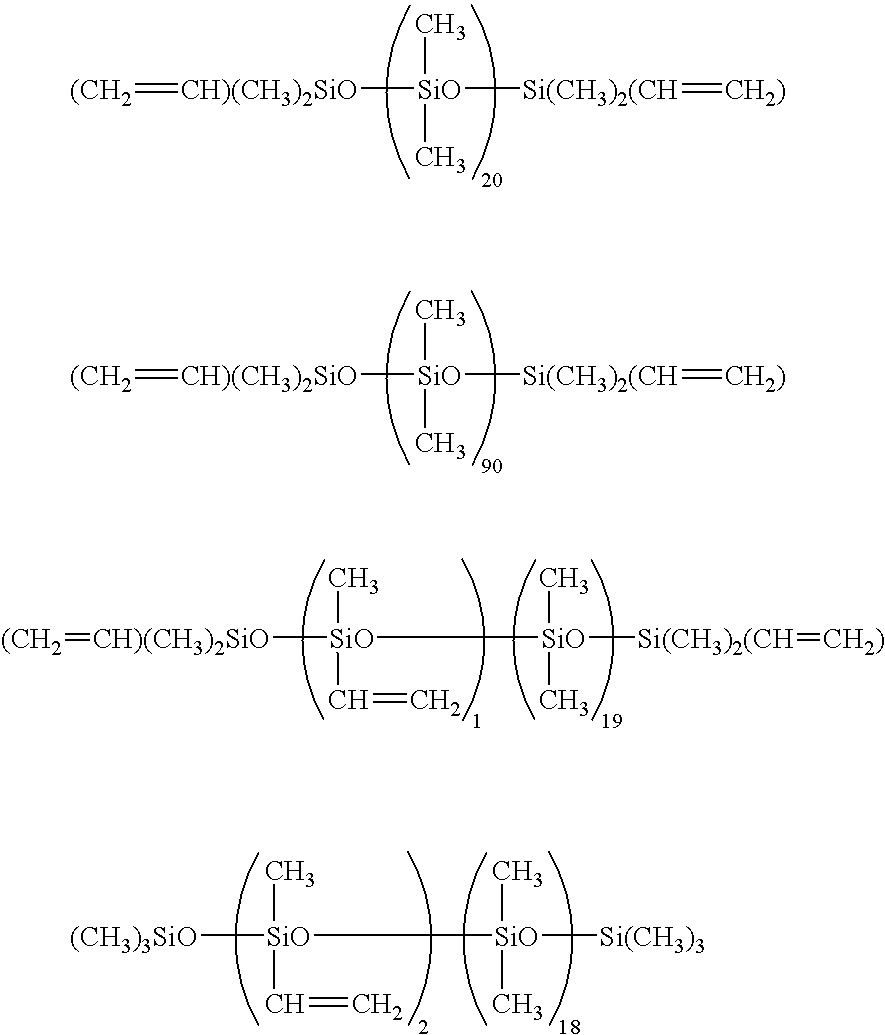

[0070](1) A linear dimethylpolysiloxane (A1) with both terminals blocked with vinyl groups and having a viscosity at 25° C. of 70 mPa·s,

[0071]a toluene solution of a silicone resin (B1) composed of Me3SiO1 / 2, ViMe2SiO1 / 2 (wherein Vi represents a vinyl group, this definition also applies below) and SiO4 / 2 units, with a molar ratio of the combination of the Me3SiO1 / 2 and ViMe2SiO1 / 2 units relative to the SiO4 / 2 units of 0.8, and having an amount of vinyl groups relative to the solid fraction of 0.085 mols / 100 g, and

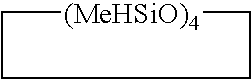

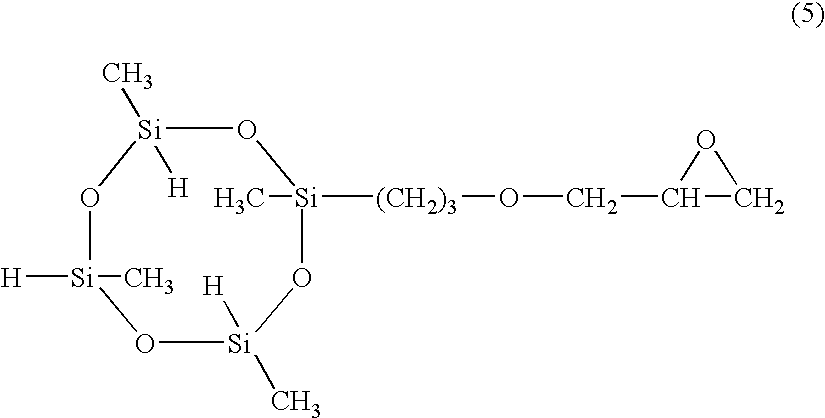

[0072]a methylhydrogensiloxane (C1) of the above average composition formula (2): R4aHbSiO(4−a−b) / 2 wherein R4 represents a methyl group, a=1.44 and b=0.78, with both terminals blocked with trimethylsiloxy groups, and having a viscosity at 25° C. of 7.5 mPa·s

[0073]were mixed together in a solid fraction equivalent mass ratio of 25:75:10. The toluene was removed from the resulting mixture by treatment at 120° C. under a reduced pressure of not more than 10 mmHg, thereby yiel...

example 2

[0075]The silicone base 1 was prepared in the same manner as example 1, and to 100 parts by mass of this silicone base 1 were added 50 parts by mass of the same titanium oxide powder (b1) used in example 1, 90 parts by mass of an alumina powder (c2) having an average particle size of 4.0 μm (product name: AL-43PC, manufactured by Showa Denko K.K.), and the same platinum catalyst (D1) used in example 1, in sufficient amount to provide the equivalent of 10 ppm of platinum atoms relative to the silicone component. The mixture was then stirred thoroughly, and 3 parts by mass of a hydrocarbon solvent with a boiling point of at least 200° C. was added, yielding a white paste with a viscosity of 20 Pa·s.

example 3

[0076]A mixture containing 45.8 g of vinylmethyldichlorosilane, 111.0 g of phenyltrichlorosilane (molar ratio 38:62) (average composition of mixture: (CH3)0.38(C6H5)0.62(CH2═CH)0.38SiO1.31) and 20 g of toluene was added gradually, in a dropwise manner, to a mixture of 120 g of toluene and 320 g of water being stirred inside a flask, with the addition controlled so that the temperature inside the flask did not exceed 50° C., thereby effecting a cohydrolysis. A polycondensation was then conducted by continuing the reaction at not more than 70° C. for two hours, thus forming a toluene solution of a three dimensional network structure organopolysiloxane (silicone resin) (P1) that exhibited a non-volatile component of 70% when heated for 30 minutes at 150° C. The solid fraction (P1) within this solution existed in a non-fluid gum-like state at 25° C. This organopolysiloxane solution was stripped for one hour under conditions of 80° C. and 15 mmHg, and to 100 parts by mass of the resultin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com