Strong anodic oxidation method for preparing porous pellumina

A technology of porous alumina and anodizing, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problem of slow growth rate of aluminum oxide film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

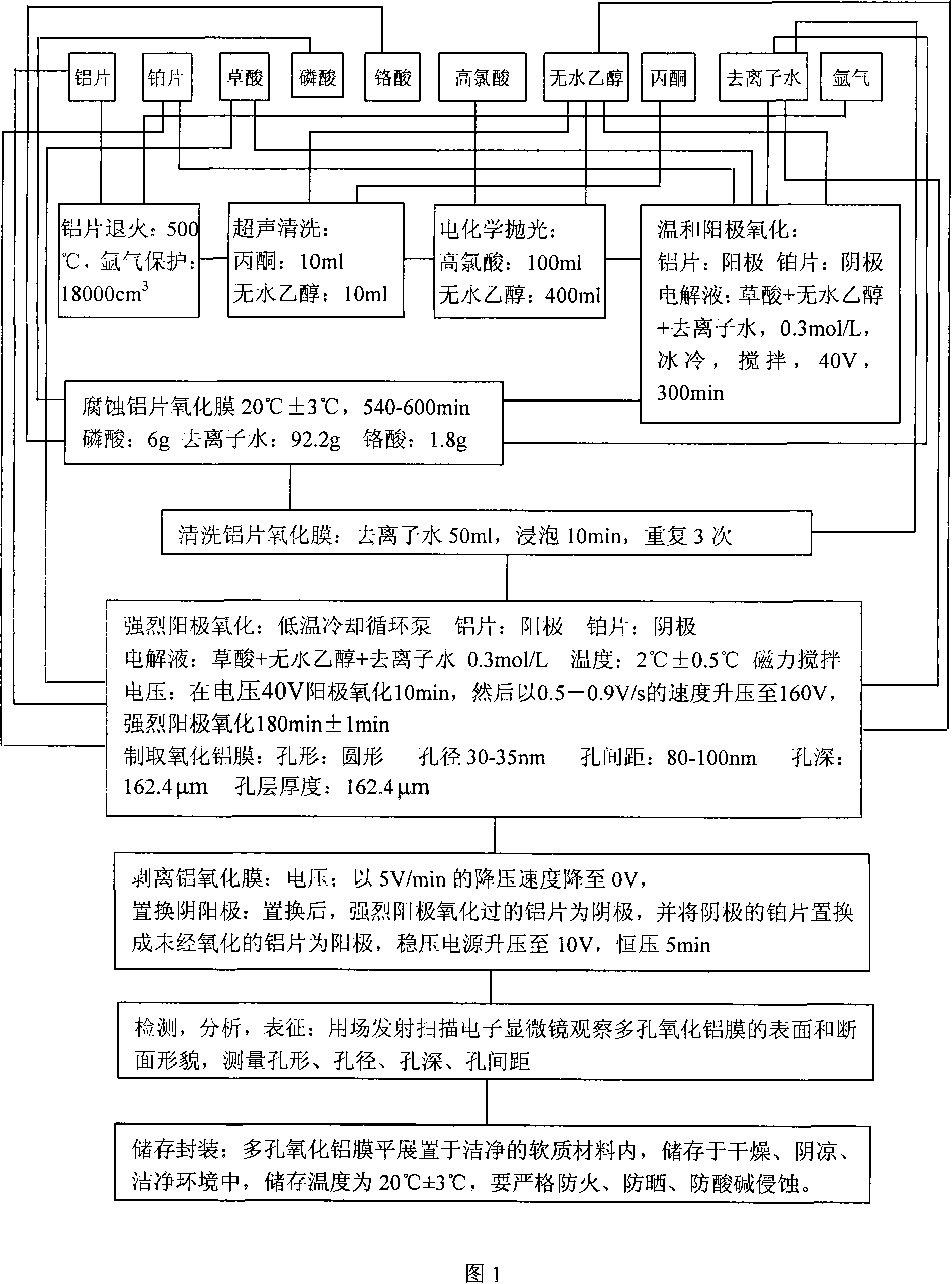

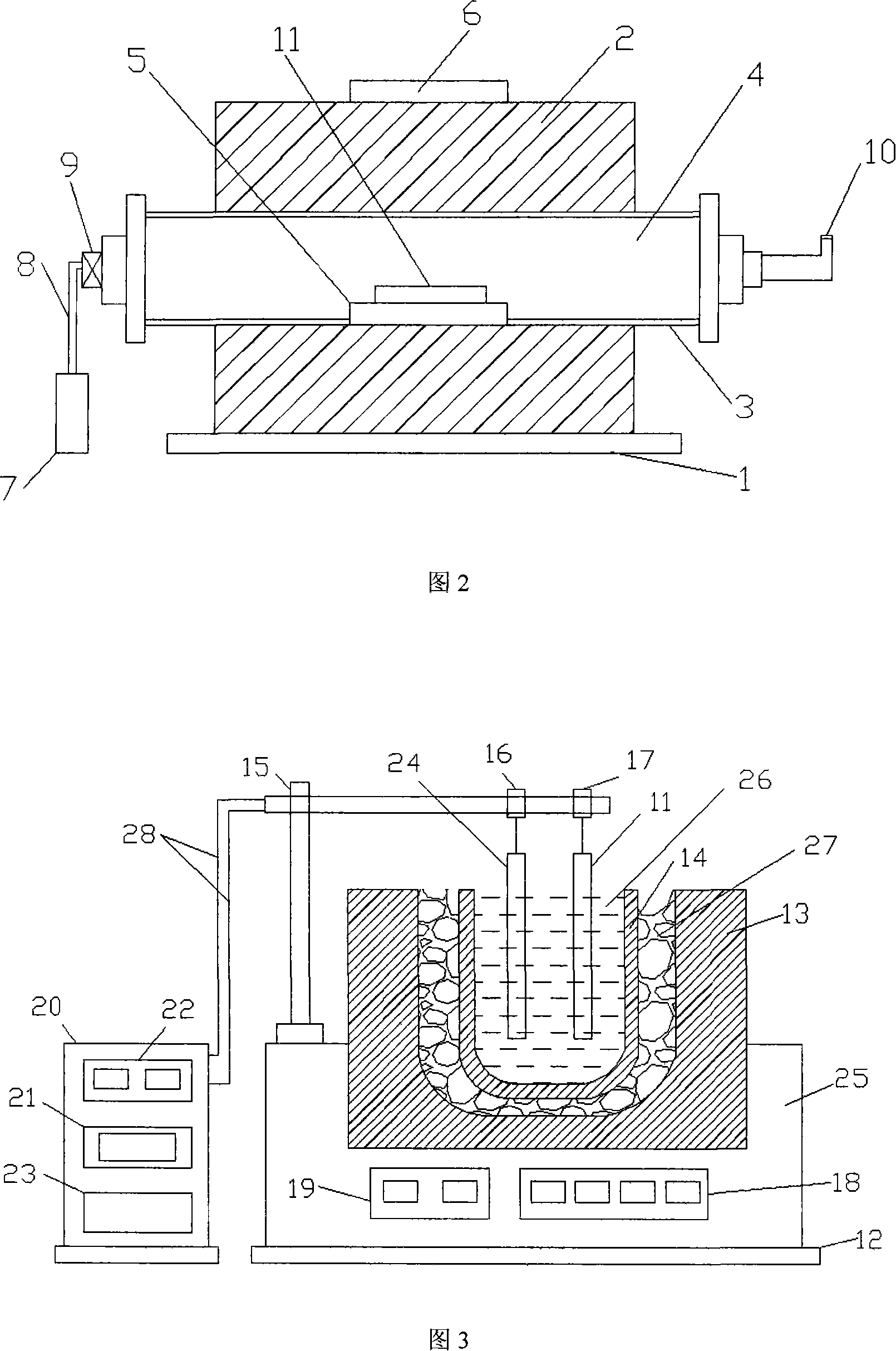

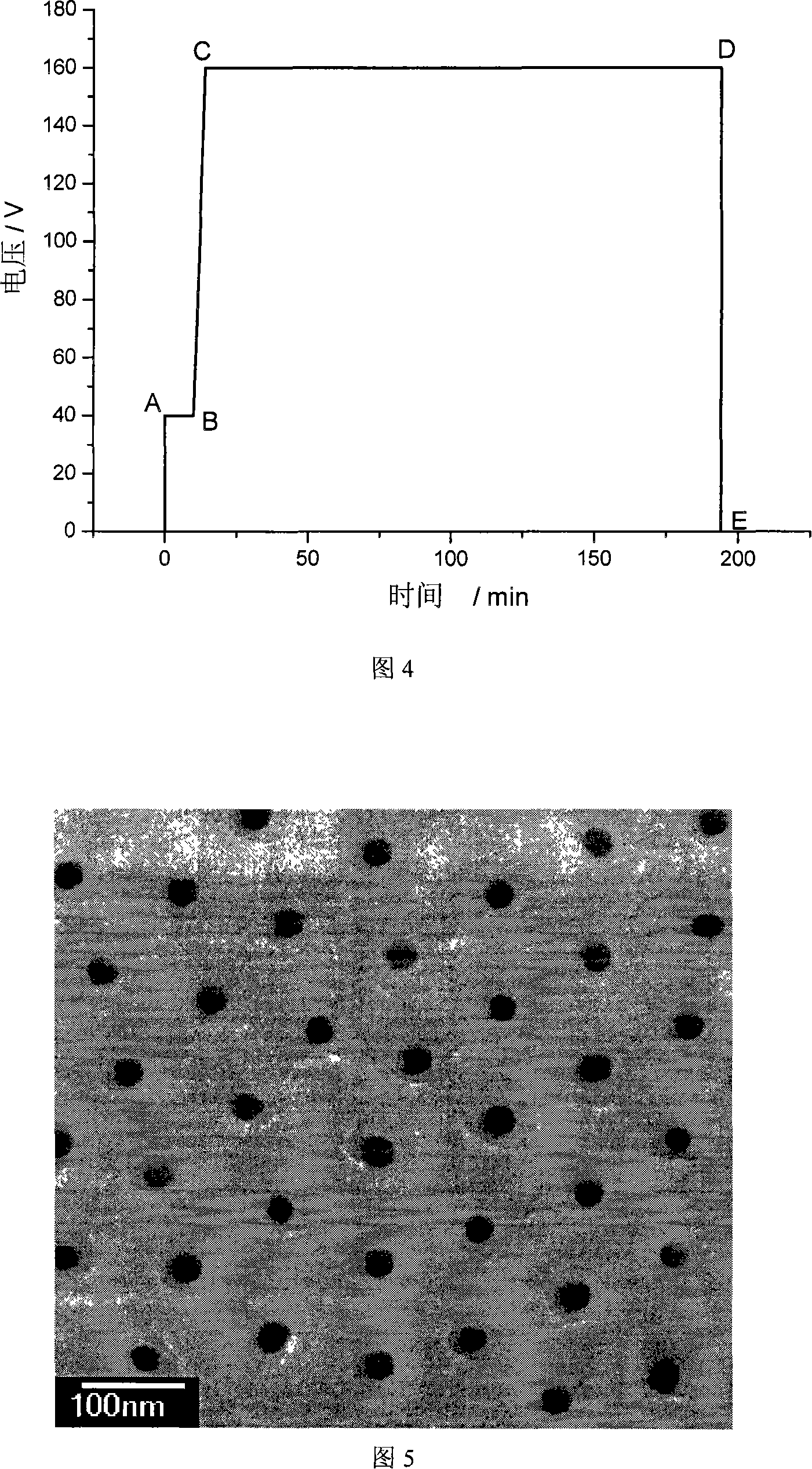

[0112] The present invention will be further described below in conjunction with accompanying drawing:

[0113] As shown in Figure 1, it is a flow chart of the preparation process, and each preparation parameter must be strictly controlled and operated in sequence.

[0114] The chemical substances and materials required by the equipment must be strictly weighed, and must not exceed the maximum and minimum ranges.

[0115] The aluminum flakes required for the preparation of porous anodized aluminum membranes must be strictly selected, with a purity of 99.999%. The dimensions, specifications, and surface roughness of the aluminum flakes and platinum flakes must be consistent, so as not to affect the voltage transmission and stability of the cathode and anode.

[0116] The annealing of aluminum sheets should be carried out in a quartz tube annealing furnace under the protection of argon gas. The annealing temperature is 500°C±3°C. The temperature and time must be strictly control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com