Composite ceramic film on surface of magnesium alloy and its forming process

A surface composite and magnesium alloy technology, applied in anodic oxidation and other directions, can solve the problems of easy formation of holes and cracks in the film layer, and achieve the effect of beautiful color, smooth surface and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

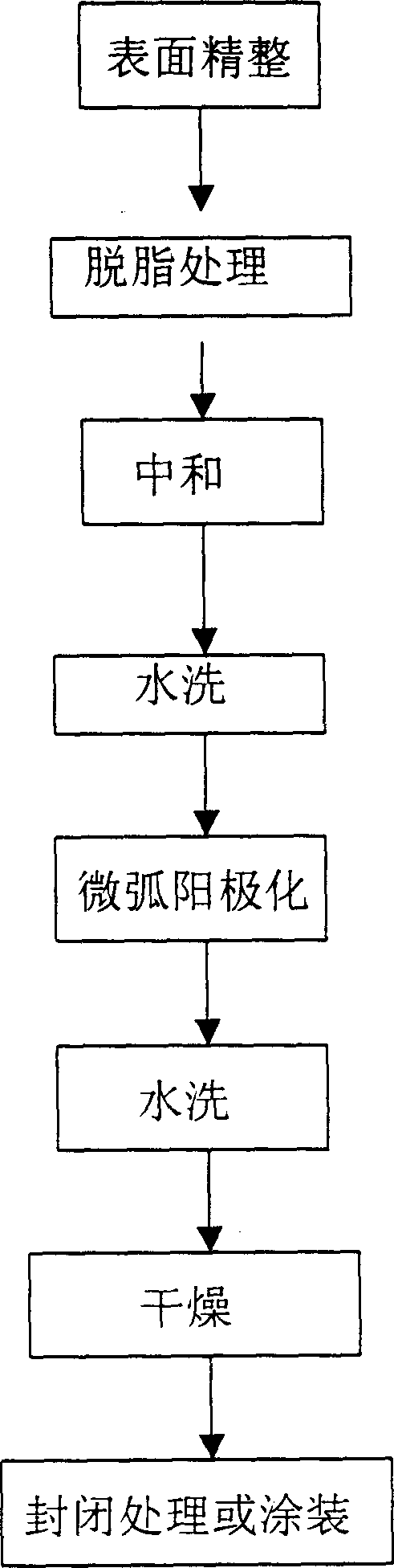

Method used

Image

Examples

Embodiment 1

[0032] The sample pretreatment process is to degrease the AZ91 magnesium alloy die-casting sample in the RR-601 cleaning agent at 35°C for 10 minutes; then, neutralize it in the RR-603 surface regulator solution at 30°C for 30 seconds, and then wash it twice Perform oxidation treatment. Electrolyte solution composition:

[0033] Ethyl silicate hydrolyzate 120g / l

[0034] Sodium citrate 50g / l

[0035] NaOH 50g / l

[0036] Potassium Lactate 15g / l

[0037] Na 3 PO 4 10g / l

[0038] Sodium metaborate 10g / l

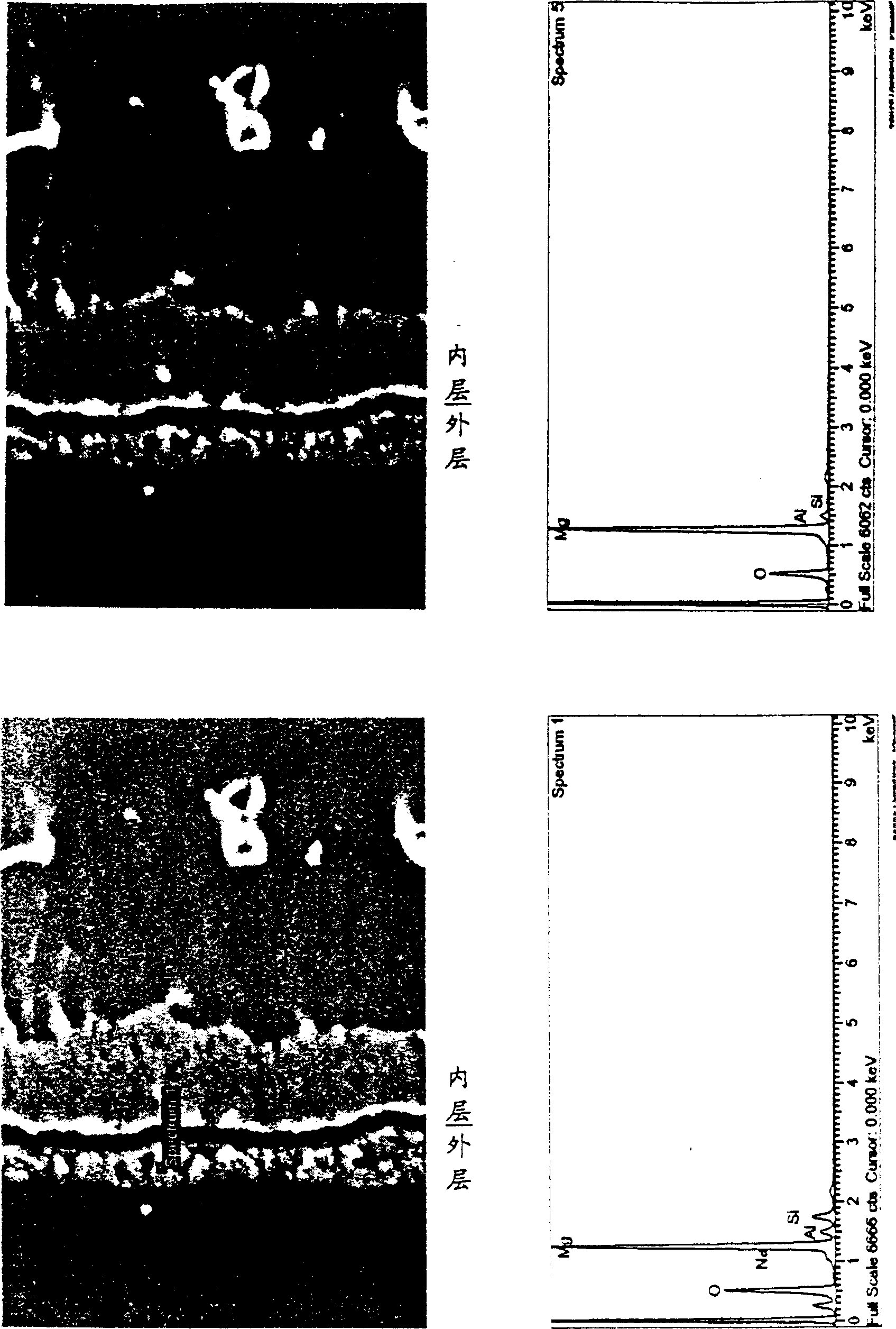

[0039] Use NaOH to adjust the pH value of the solution to 12 Micro-arc oxidation: temperature 35°C; voltage 100V; 10 minutes film quality: milky white, uniform, complete, smooth film, the total thickness of the inner and outer layers is 40 μm.

Embodiment 2

[0041] The sample pretreatment process is to ultrasonically degrease the AZ91 magnesium alloy die-casting sample in the RR-601 cleaning agent at 30°C for 15 minutes; then, neutralize it in the RR-603 surface conditioner solution at 25°C for 50 seconds, and perform two water washes followed by oxidation treatment. The electrolyte solution consists of:

[0042] Potassium silicate 100ml / l

[0043] Sodium citrate 50g / l

[0044] NaOH 50g / l

[0045]Sodium acetate 10g / l

[0046] Na 3 PO 4 10g / l

[0047] NaF 2g / l

[0048] PH value 10 micro-arc oxidation: temperature 35°C; electric jade 100V; 5 minutes, the rest are the same as in Example 1. Film quality: milky white, uniform, complete, smooth film, the total thickness of the inner and outer layers is 35 μm.

Embodiment 3

[0050] The electrolyte solution consists of:

[0051] Sodium silicate 80g / l

[0052] Sodium Potassium Tartrate 70g / l

[0053] Sodium Lactate 10g / l

[0054] Na 3 PO 4 10g / l

[0055] NaOH 20g / l

[0056] pH 11

[0057] The pretreatment conditions are basically the same as in Example 2. Micro-arc oxidation: temperature 45°C; voltage 90V; time 4 minutes Film quality: light orange, uniform, complete, smooth film, the total thickness of the inner and outer layers is 24 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com