Composite manufacturing method of ultra-thick steel plate

A manufacturing method and a technology of extra-thick steel plates, which are applied in the field of steel rolling in the metallurgical industry, can solve problems such as difficult operations, long processes, and low efficiency, and achieve the effects of good internal quality, reasonable processes, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through embodiment.

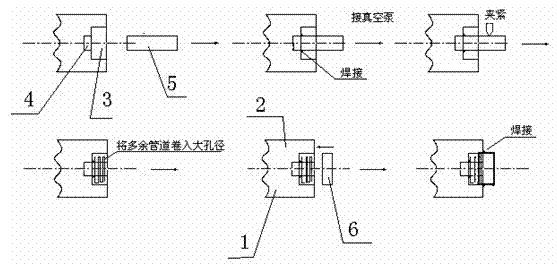

[0018] The process flow of the present invention is as follows: base material and cladding material preparation process → base material and cladding material surface treatment process → composite surface edge welding combined billet making process → high temperature hydrogen reduction process → composite cavity vacuuming and sealing process → heating and rolling Manufacturing process → hot straightening process → cooling and inspection process → finished product collection and warehousing process.

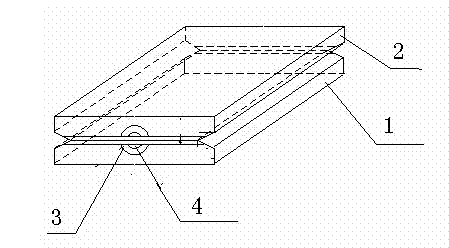

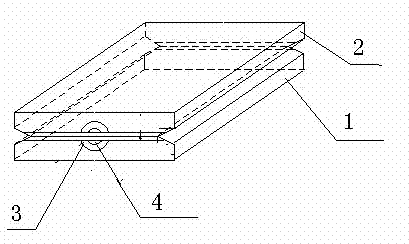

[0019] Refer to attached figure 1 , 2 , in the embodiment, the surface treatment process of the base material and the cladding material: use a planer or milling machine to grind and derust the single side of the steel plate that needs to be combined, and the grinding depth is to completely remove the surface oxide scale and control the surface roughness ≤ 25 μm; Mill out 10×10mm chamfers on the fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com