Method for producing aluminium oxide by middle-low grade alumyte

A technology for low-grade bauxite and alumina, applied in aluminate/alumina/aluminum hydroxide purification, chemical instruments and methods, alumina/aluminum hydroxide, etc. Realize industrialization, solution is difficult to obtain and other problems, to achieve the effect of improving utilization rate, reducing the amount of red mud, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

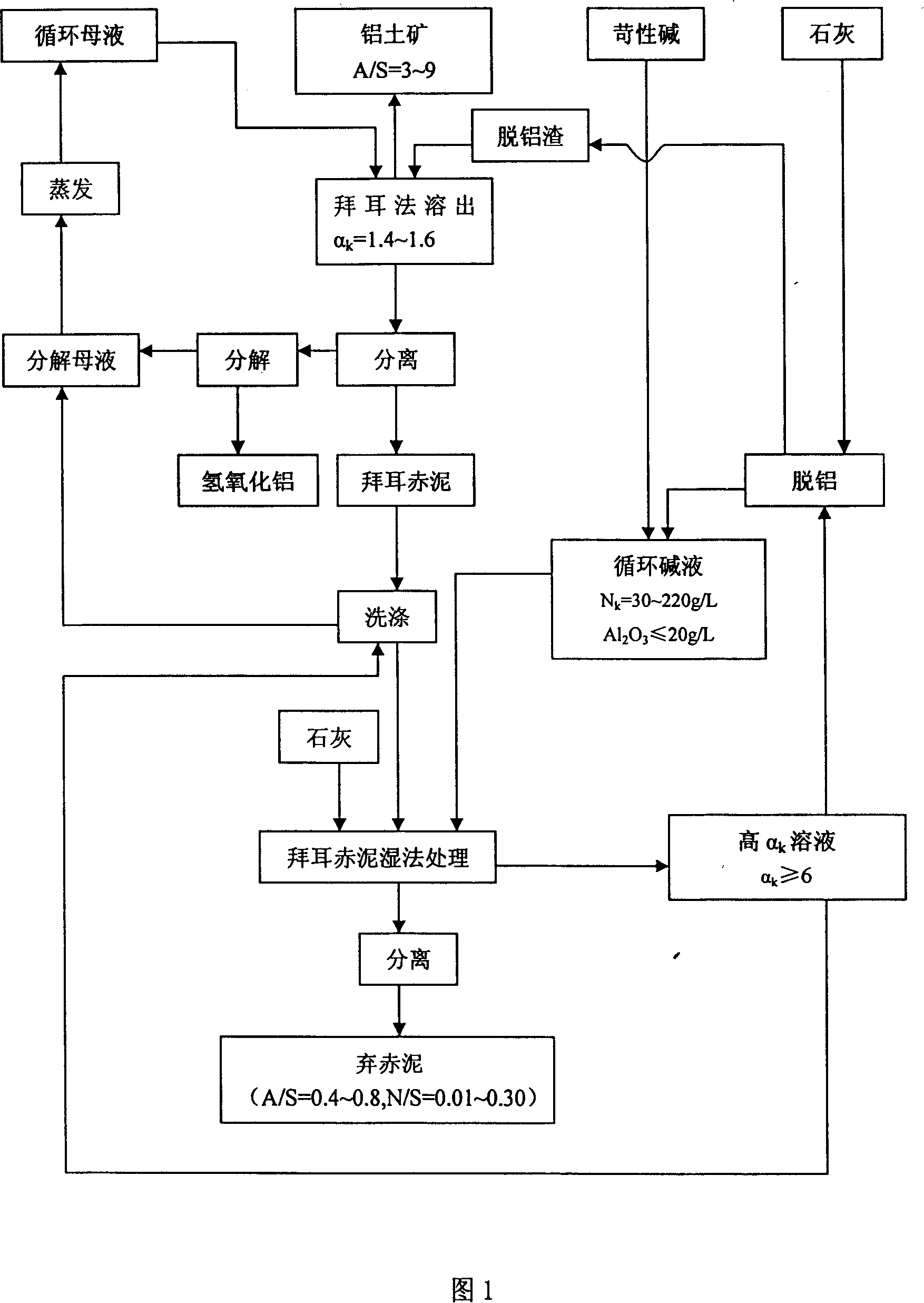

Method used

Image

Examples

Embodiment 1

[0021] The aluminum-silicon ratio A / S of bauxite is 3, the dissolution temperature of the Bayer method is 250°C, and the caustic alkali concentration of the circulating lye is N k is 230g / L, a K It is 3.0, and the dealuminated slag produced in the regeneration process of circulating alkaline solution is used as the stripping additive with Bayer process red mud wet method, and the stripping time is 90min, and the stripping liquid a K The aluminum-silicon ratio of the dissolved red mud is 1.48, and the ratio A / S of the dissolved red mud is 1.5; the temperature of the Bayer red mud wet treatment is 290°C, the concentration of the circulating lye is 30g / L, the calcium-silicon ratio of the total lime added is 1.0, and the dissolution time is 20min. The aluminum-silicon ratio A / S of red mud is 0.5, and the sodium-silicon ratio N / S is 0.10.

Embodiment 2

[0023] The aluminum-silicon ratio A / S of bauxite is 4, the Bayer process dissolution temperature is 260°C, and the caustic alkali concentration Nk of the circulating lye is 230g / L, a K is 3.0, the dissolution time is 60min, and the dissolution liquid a k The aluminum-silicon ratio of the dissolved red mud is 1.50, and the ratio A / S of the dissolved red mud is 1.4; the temperature of the Bayer red mud wet treatment is 260°C, the concentration of the circulating lye is 90g / L, the calcium-silicon ratio of the total lime addition is 1.2, and the dissolution time is 90min. The aluminum-silicon ratio A / S of red mud is 0.60, and the sodium-silicon ratio N / S is 0.15.

Embodiment 3

[0025] The aluminum-silicon ratio A / S of bauxite is 5, the Bayer process dissolution temperature is 270°C, and the caustic alkali concentration Nk of the circulating lye is 230g / L, a K is 3.0, the dissolution time is 60min, and the dissolution liquid a K The aluminum-silicon ratio of the dissolved red mud is 1.50, the ratio A / S of the leached red mud is 1.30; the temperature of the Bayer red mud wet treatment is 250°C, the concentration of the circulating lye is 130g / L, the calcium-silicon ratio of the total lime addition is 1.4, and the dissolution time is 80min. The aluminum-silicon ratio A / S of red mud is 0.65, and the sodium-silicon ratio N / S is 0.18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com