Production process of semiwater-diaquo phosphoric acid

A production method, phosphoric acid technology, applied in the direction of chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as unsuitable process conditions for production, limited production capacity of equipment, etc., to prolong the period of plugging removal, high production efficiency, and improve The effect of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

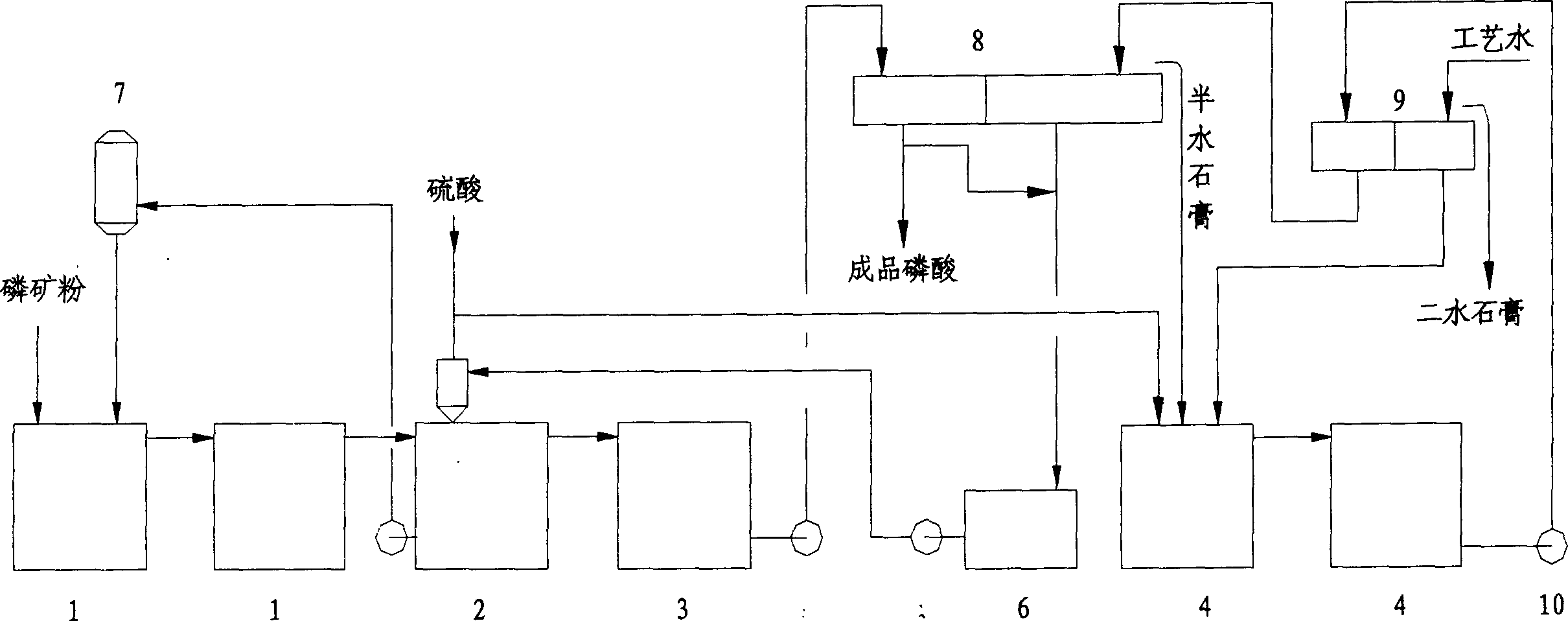

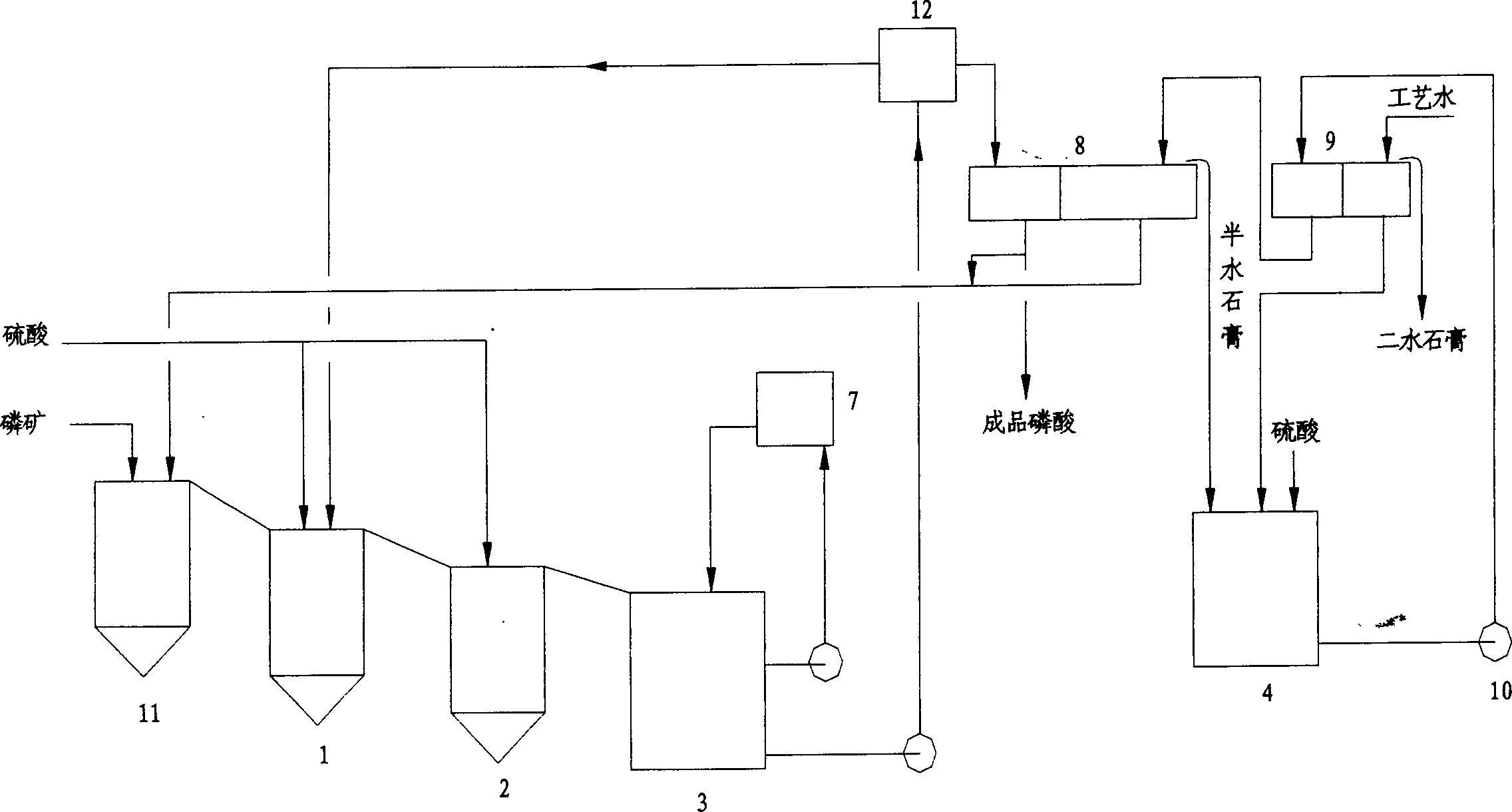

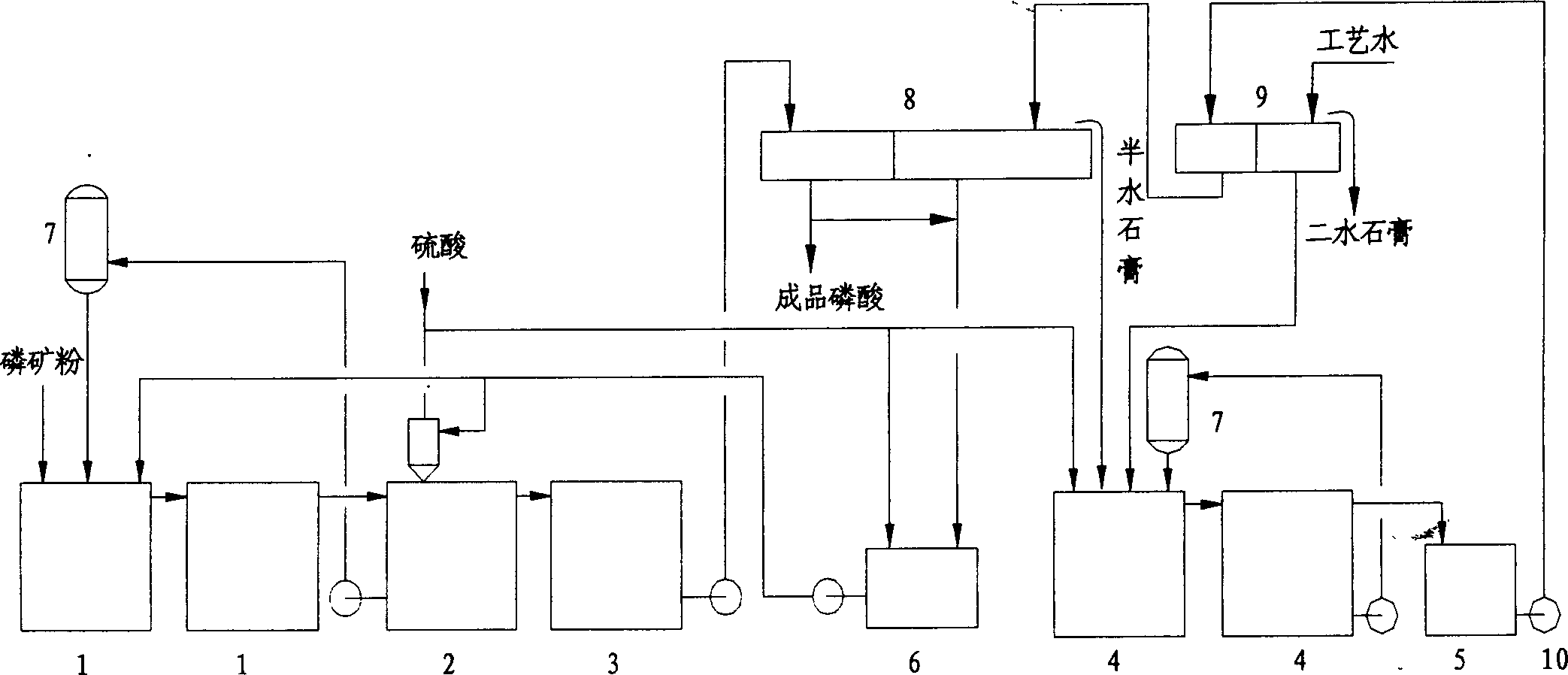

[0021] The following is a specific comparison between the prior art and the process flow of the present invention in conjunction with the accompanying drawings, so as to describe the content of the present invention in more detail, but the content of the present invention is not limited to what is shown in the accompanying drawings.

[0022] Such as figure 1 As shown, according to the Norsk-Dhetero process, phosphate rock powder is added to the first tank, and the volume of the first tank is larger, which is twice that of the second tank; sulfuric acid and dilute phosphoric acid are added to the second tank, and the slurry is from The second tank is pumped into the vacuum flash cooler 7 and then flows into the first tank. In the first tank, 40% of the CaO brought in by phosphate rock is controlled to form CaSO 4 .0.5H 2 O, and the remaining 60% CaO exists in the slurry in the form of monocalcium phosphate, which is the technical characteristic of the Norsk Hetero process. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com