Monox powder containing Li and its manufacture

A technology of lithium silicon oxide and powder, which is applied in the field of manufacturing this lithium-containing silicon oxide powder, can solve problems such as not clearly describing lithium-containing silicon oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] 200g of SiO with a weight ratio of 90:10 was loaded into the silicon nitride tray z Powder (z=1.05, BET specific surface area=33.5m 2 / g) and the mixture of lithium hydroxide hydrate are placed in a reaction furnace with an effective volume of 15 liters. While argon gas was flowing through the furnace at a flow rate of 10 NL / min, the reaction was performed at a temperature of 900° C. for 3 hours to obtain 160 g of raw lithium-containing silicon oxide powder. The BET specific surface area of unprocessed powder is 5.8m 2 / g.

[0039] 100 g of raw powder was ground in a 2 liter alumina ball mill using 1000 g of alumina balls with a diameter of 5 mm as grinding media and 500 g of hexane as solvent, working at 1 rpm. At the end of milling, the lithium-containing silica powder has an average particle size D of 4.3 μm 50 、14.2m 2 / g BET specific surface area, 1.3wt% lithium content and 33.5wt% oxygen content, by the general formula SiLi x o y Indicates that x=0.08, y=...

example 2-6 and comparative example 1-5

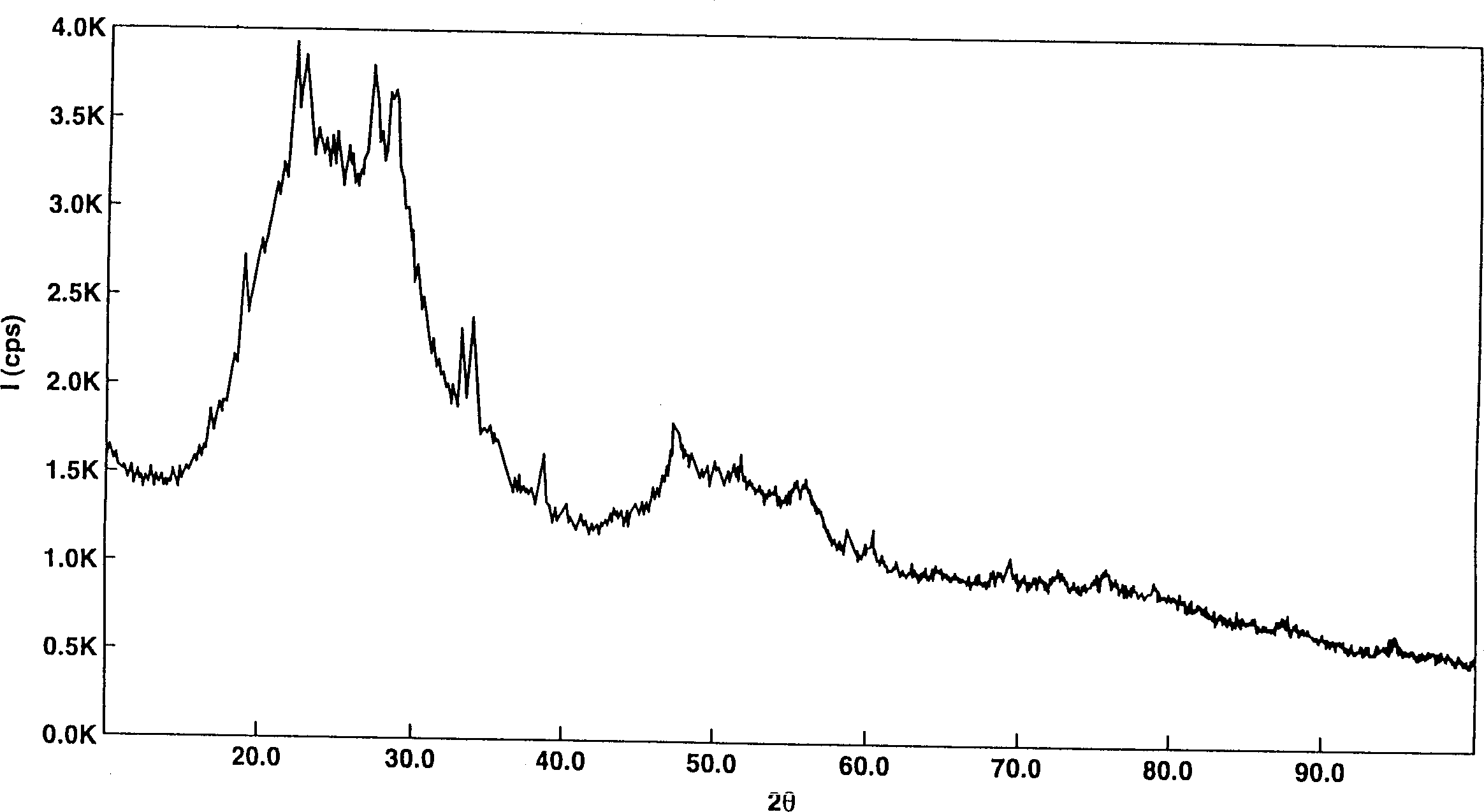

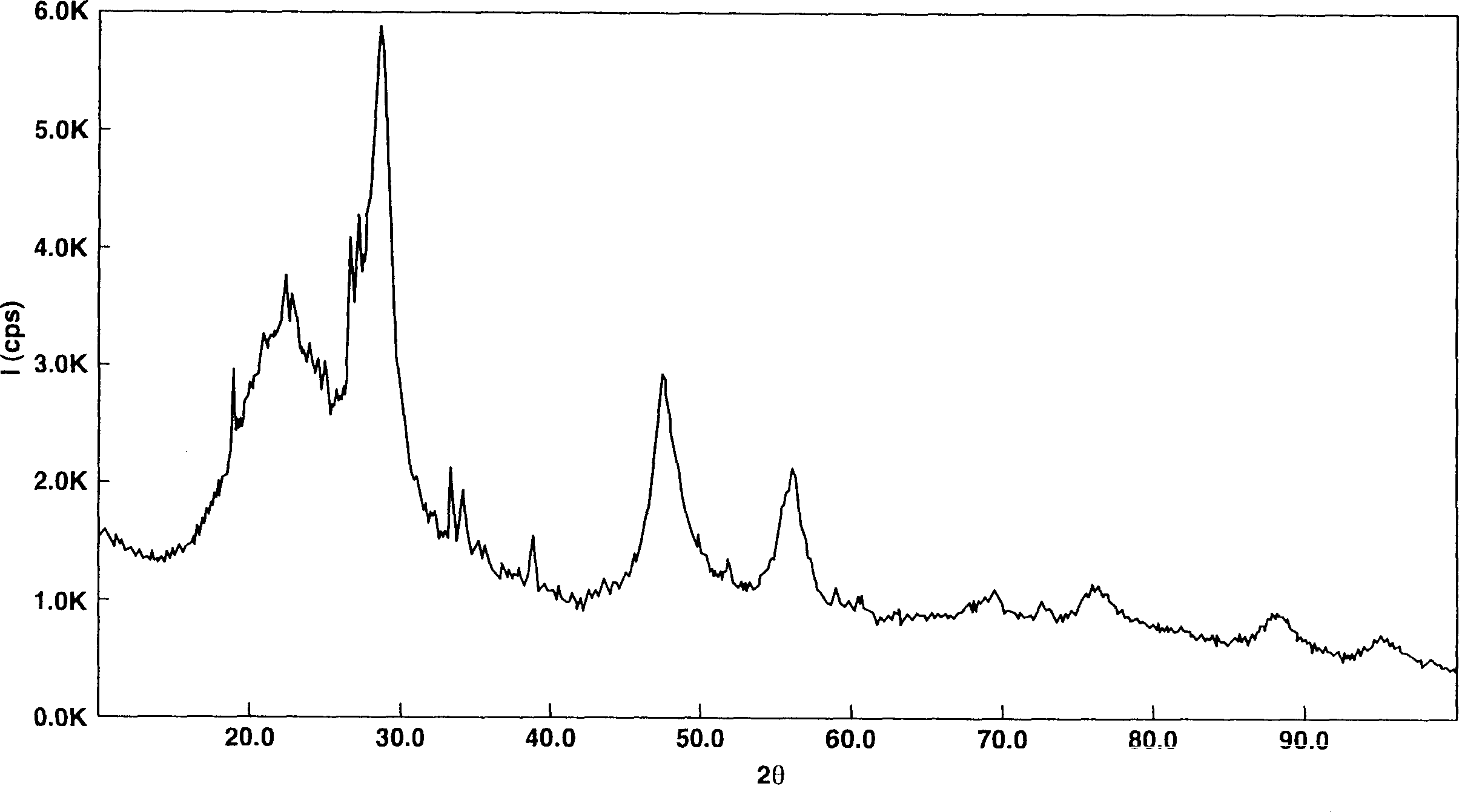

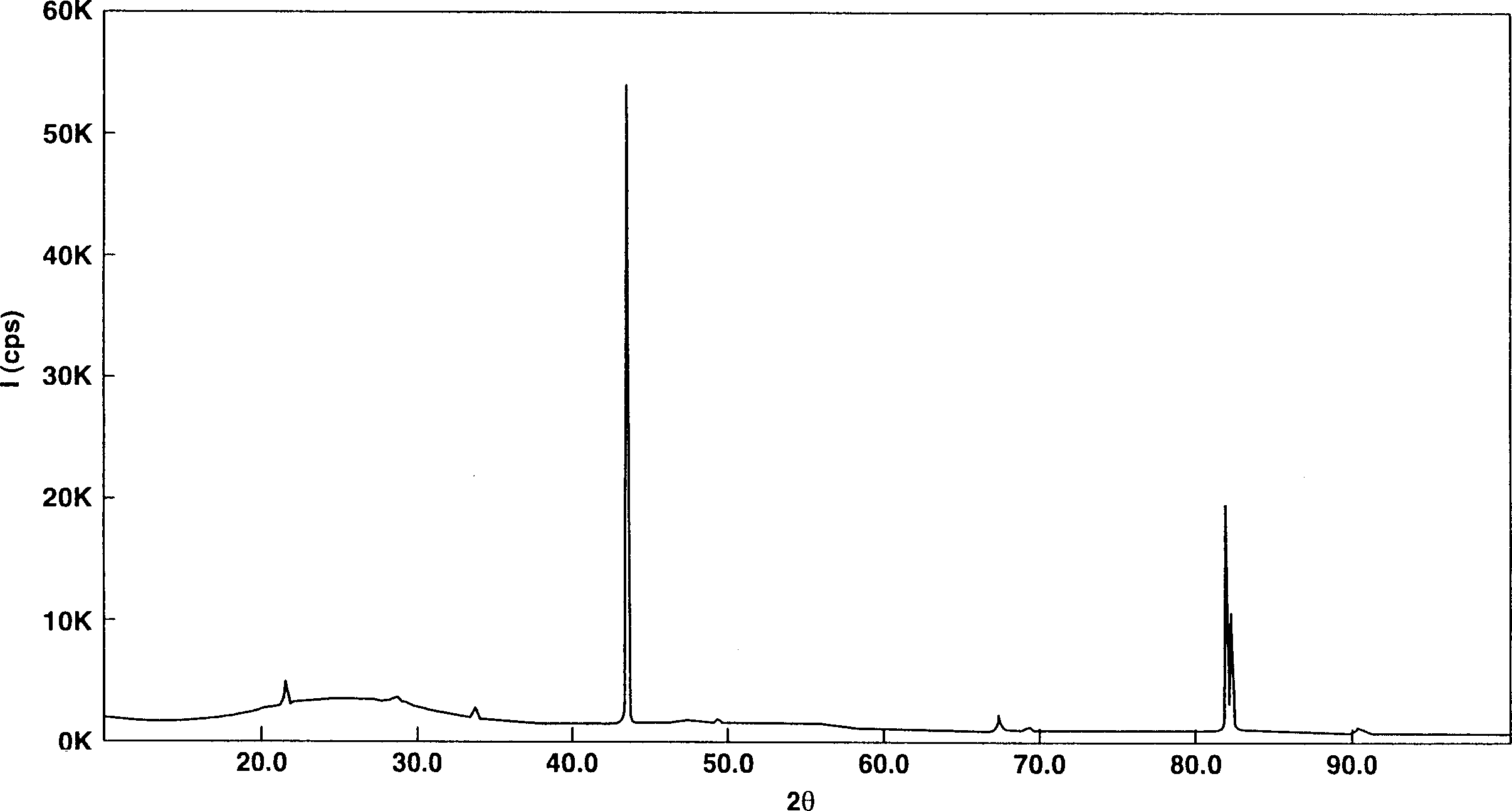

[0045] In addition to the raw material SiO z , lithium compound, SiO z Lithium-containing silicon oxide powder was prepared in the same manner as in Example 1 except that the / lithium compound ratio and reaction temperature were changed as shown in Table 1. Measure the recovered amount and BET specific surface area of the obtained unprocessed lithium-containing silicon oxide powder; measure the average particle diameter D of the refined lithium-containing silicon oxide powder 50 , BET specific surface area, lithium content and oxygen content. These results are listed in Table 2 together with the compositions (values of x and y in the general formula) calculated from the lithium and oxygen contents. The presence or absence of amorphous lithium silicon oxide and crystallized lithium silicon oxide was checked by x-ray diffraction measurement. The results are shown in Table 2. figure 2 and 3 These are the X-ray diffraction patterns of the (lithium-containing silicon oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com