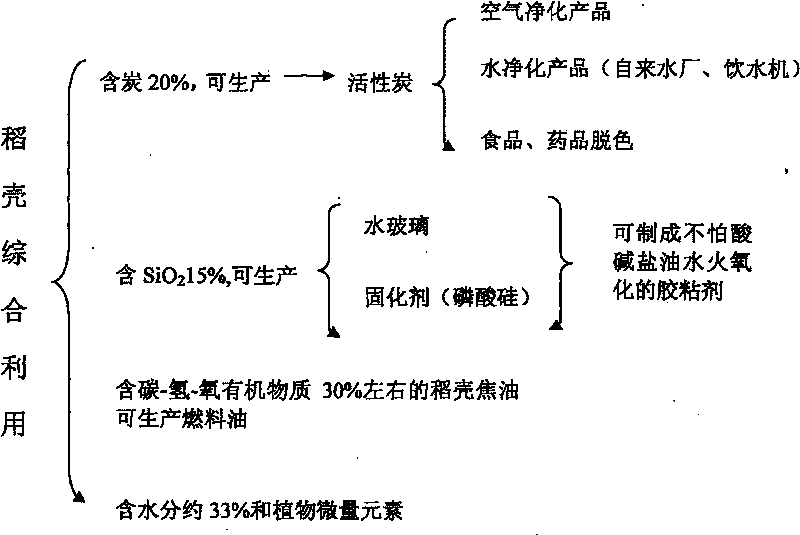

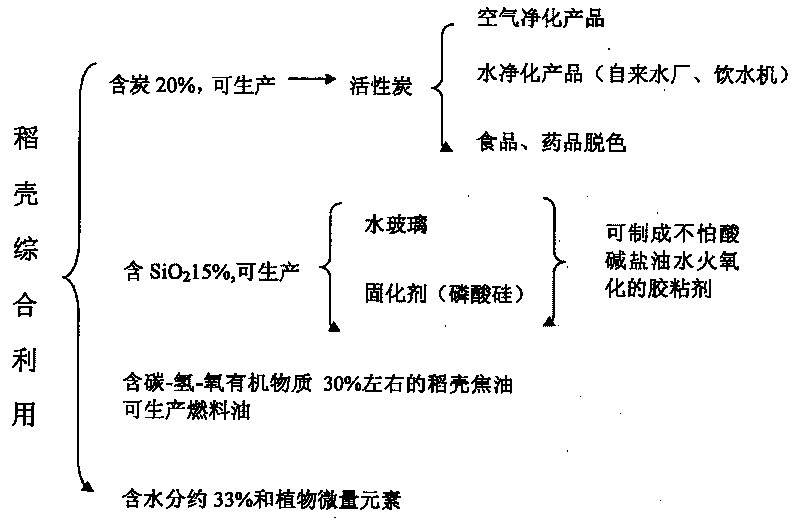

Method for preparing active carbon and rice hull tar by comprehensively utilizing rice hulls and co-producing water glass or silicon phosphate

A technology of activated carbon and water glass, applied in chemical instruments and methods, silicates, coke ovens, etc., can solve problems such as low product quality, low output, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

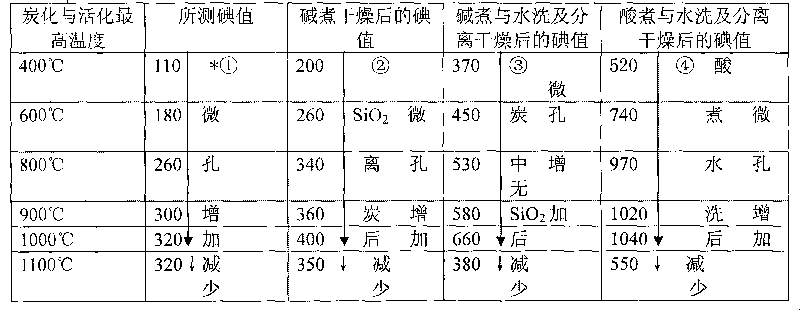

Embodiment 1

[0037] The rice husk is made into activated carbon with high adsorption value and high modulus water glass, the steps are:

[0038] Transport the pure rice husk to the stainless steel sieve on the top of the heating carbonization activation furnace, heat the furnace, adjust the voltage, make the temperature of the bottom of the furnace reach about 800 °C, and the temperature of the top of the furnace reach about 400 °C, and keep it stable, start the motor to make the steel The sieve vibrates horizontally so that the rice husks on the sieve are continuously sieved into the furnace and carbonized into charcoal husks. flow to the condenser. After the stainless steel sieve started to vibrate for about 20 minutes, about 180kg of charcoal husks (about 500kg of rice husks had been sieved) were piled up in the furnace. At this time, the carbonized rice husks were transferred to the pool filled with sodium hydroxide alkali solution.

[0039] According to the above steps, about 12 tons...

Embodiment 2

[0049] While producing gac and water glass, produce the method for rice husk tar, its step is:

[0050] When the hot gas in the furnace in Example 1 passes through the condenser, the gas is condensed into a liquid state for storage, and 1 ton of activated carbon can be produced to obtain about 1 ton of tar.

[0051] After preliminary testing, the tar contains about 15% of low boiling point (≤250°C) oil, 20% of medium boiling point (≤300°C) oil, 30% of high boiling point (≤400°C) oil, and ultra-high boiling point (≤600°C) oil 10%, the rest is solid oil residue (similar to asphalt).

Embodiment 3

[0053] Curing agent for making rice husk into water glass - silicon phosphate [Si 3 (PO 4 ) 4 or SiP 2 o 7 ] method, its steps are:

[0054] The carbonized rice husk produced by the steps of Example 1 falls into the pond filled with phosphoric acid solution while it is hot, and stirs rapidly. The concentration of phosphoric acid solution in the pond is about 40%, and the solution weight is 2.5% of the shell carbon weight in the pond. times (about 430kg). Heat to 100-150°C, stir and keep warm for 2-5 hours, filter to obtain filtrate and carbon residue, and obtain about 300kg of silicon phosphate aqueous solution after solid-liquid separation, with a concentration of about 38 degrees Baume and a density of about 1.43g / cm 3 . Dry the above-mentioned silicon phosphate aqueous solution to a paste, then put the paste into a high-temperature porcelain barrel (or crucible), cover it, and put it into a furnace. Raise the temperature to about 720°C at a rate of 60°C / hour, and kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com