Display substrate, manufacturing method thereof and display device

A display substrate and mixed light technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of high elastic recovery rate, refined size and height, and cannot be obtained at the same time, and achieve high elastic recovery rate and refined size and height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

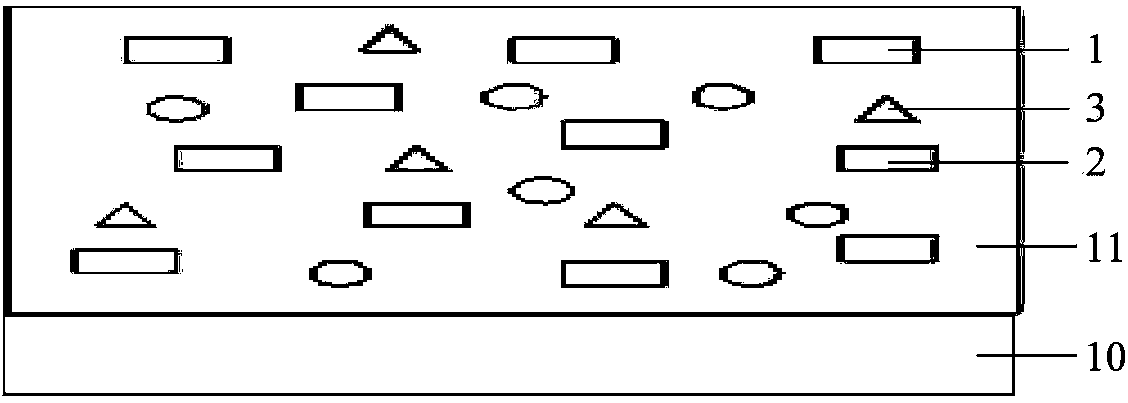

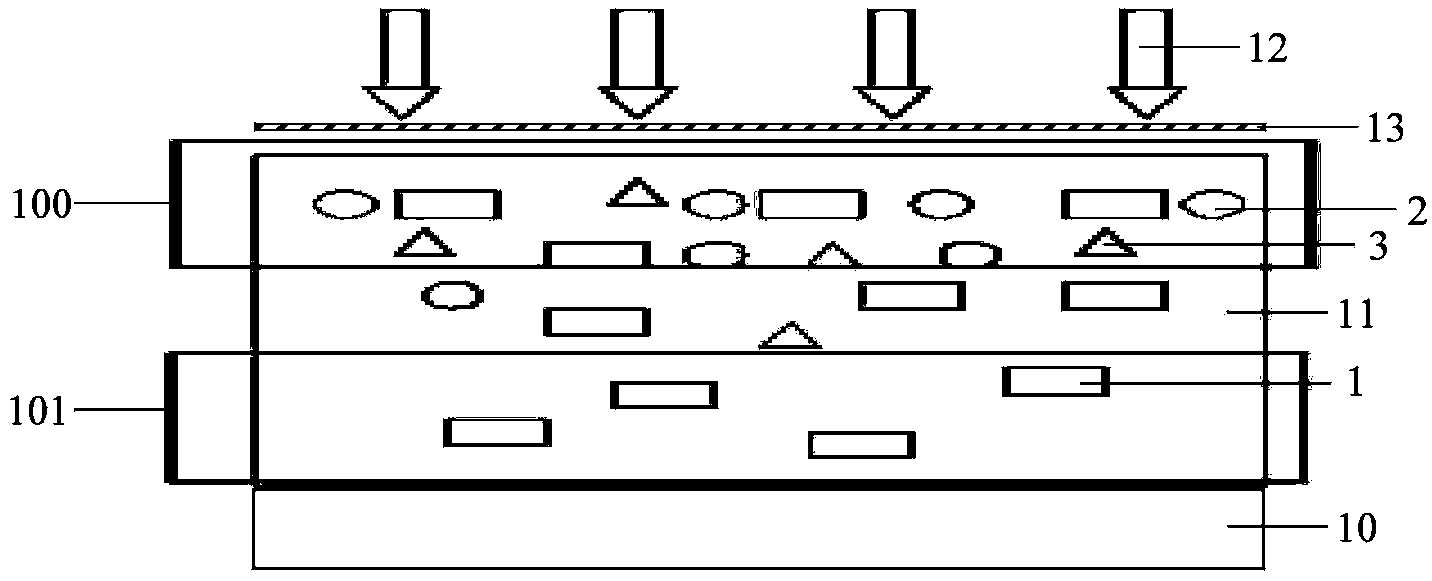

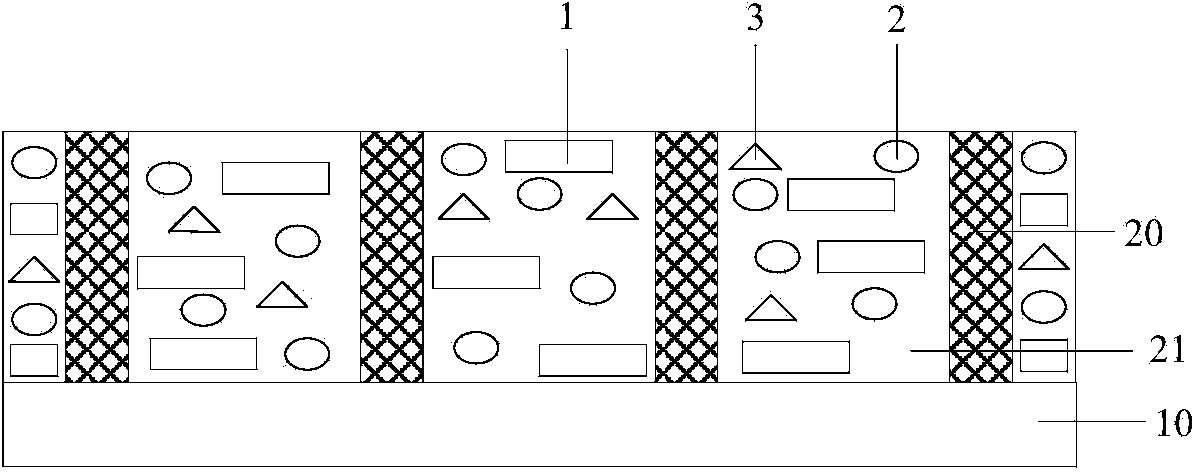

[0037] In a liquid crystal display device, the cell thickness uniformity of the display panel is one of the important factors affecting the display quality. Therefore, the spacer required to support the thickness of the display panel box must have a high enough elastic recovery rate and a sufficiently refined size and height.

[0038] Existing spacers are usually columnar spacers made of negative photoresist materials (the part irradiated by light will not be removed by the developer, while the part not irradiated by light can be removed by the developer), for example: The negative photoresist material may be composed of acrylate or epoxy resin copolymer, and corresponding crosslinking agent and photoinitiator are added to the acrylate or epoxy resin copolymer. Among them, acrylate and epoxy resin are photopolymerizable monomers, which will undergo polymerization reaction to form polymer after being irradiated by light. The role of the photoinitiator is to catalyze the polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com