Preparation method for polyurethane chip for high-temperature-resistant fibers

A high-temperature-resistant fiber and polyurethane technology, which is applied in the field of polyurethane chip preparation, can solve the problems of high processing temperature, poor resilience and heat resistance, and difficult quality control of melt-spun spandex.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

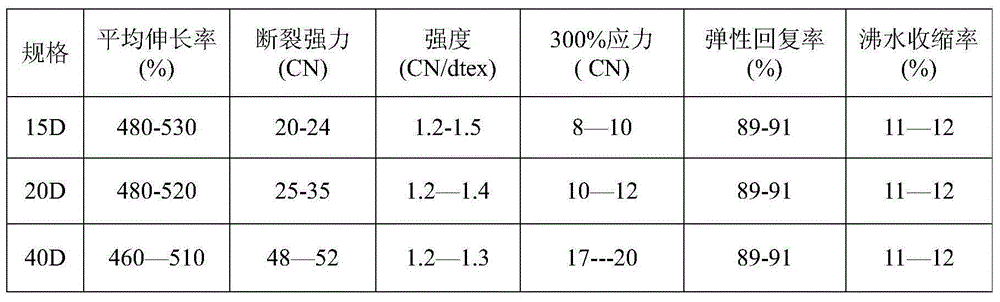

Image

Examples

Embodiment 1

[0022] Under nitrogen protection, stir terephthalic acid: adipic acid: 1,4-butanediol in a molar ratio of 10:40:70 at 50°C until uniform; , quickly raised the temperature to 100°C to start the reaction, raised the temperature to 235°C within 2 hours, and discharged the generated water to obtain a clear liquid; press the liquid into the polycondensation kettle, keep the temperature at 230°C, quickly reduce the pressure to 30kPa, and keep the temperature constant Change, the pressure is gradually reduced to 100Pa within 1h, and the reaction is completed to obtain polyester polyol with a molecular weight of 3000Da.

[0023] Use a metering pump to prepare polycarbonate polyol, 1,4-butanediol, hexamethylene diisocyanate, nano-silica, and nano-silica in a gas-phase method at a molar ratio of 1.03:0.97:2. The added amount is 1% of the total weight of raw materials, injected into reaction twin-screw with aspect ratio of 65, reacted at 120-190°C, granulated under water, dried and packa...

Embodiment 2

[0026] Under nitrogen protection, stir phthalic acid: succinic acid: 1,4-butanediol in a molar ratio of 15:35:60 at 60°C until uniform; , quickly raised the temperature to 100°C to start the reaction, raised the temperature to 260°C within 2 hours, and discharged the generated water to obtain a clear liquid; press the liquid into the polycondensation kettle, keep the temperature at 245°C, quickly reduce the pressure to 30kPa, and keep the temperature constant Change, the pressure is gradually reduced to 100Pa within 1h, and the reaction is completed to obtain polyester polyol with a molecular weight of 4000Da.

[0027] Use a metering pump to drive polycarbonate polyol, 1,4-cyclohexanedimethanol, 4,4'-diphenylmethane diisocyanate, and nano-magnesium hydroxide into the long diameter at a molar ratio of 1.03:0.97:2 In a reaction twin-screw with a ratio of 75, the reaction temperature is 120-190°C, the product is granulated under water, dried and packaged. Weight average molecula...

Embodiment 3

[0030] Under nitrogen protection, stir terephthalic acid: glutaric acid: 1,4-butanediol in a molar ratio of 55:55:75 at 60°C until uniform; , quickly raised the temperature to 100°C to start the reaction, raised the temperature to 240°C within 2 hours, and discharged the generated water to obtain a clear liquid; press the liquid into the polycondensation kettle, keep the temperature at 235°C, quickly depressurize to 30kPa, and keep the temperature constant Change, the pressure is gradually reduced to 100Pa within 1h, and the reaction is completed to obtain polyester polyol with a molecular weight of 2000Da.

[0031] Use a metering pump to mix polycarbonate polyol, 1,4-cyclohexanedimethanol and 1,4-butanediol mixture, 4,4'-diphenylmethane diisocyanate at a molar ratio of 1.03:0.97:2 , Nano-calcium carbonate is injected into the reaction twin-screw with an aspect ratio of 85, the reaction temperature is 120-190°C, the product is granulated under water, dried and packaged. Weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com