Surface material for vehicle use, producing method thereof, internal decorative material and seat material for automatic two-wheel and tricycle vehicles

A technology for skin materials and vehicles, applied in vehicle parts, dyeing methods, transportation and packaging, etc., can solve the problems of poor reproducibility, labor, and increased cost of fabric dyeing, achieving excellent functionality, reducing environmental burden, and saving energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be specifically described based on examples of the present invention shown in the drawings.

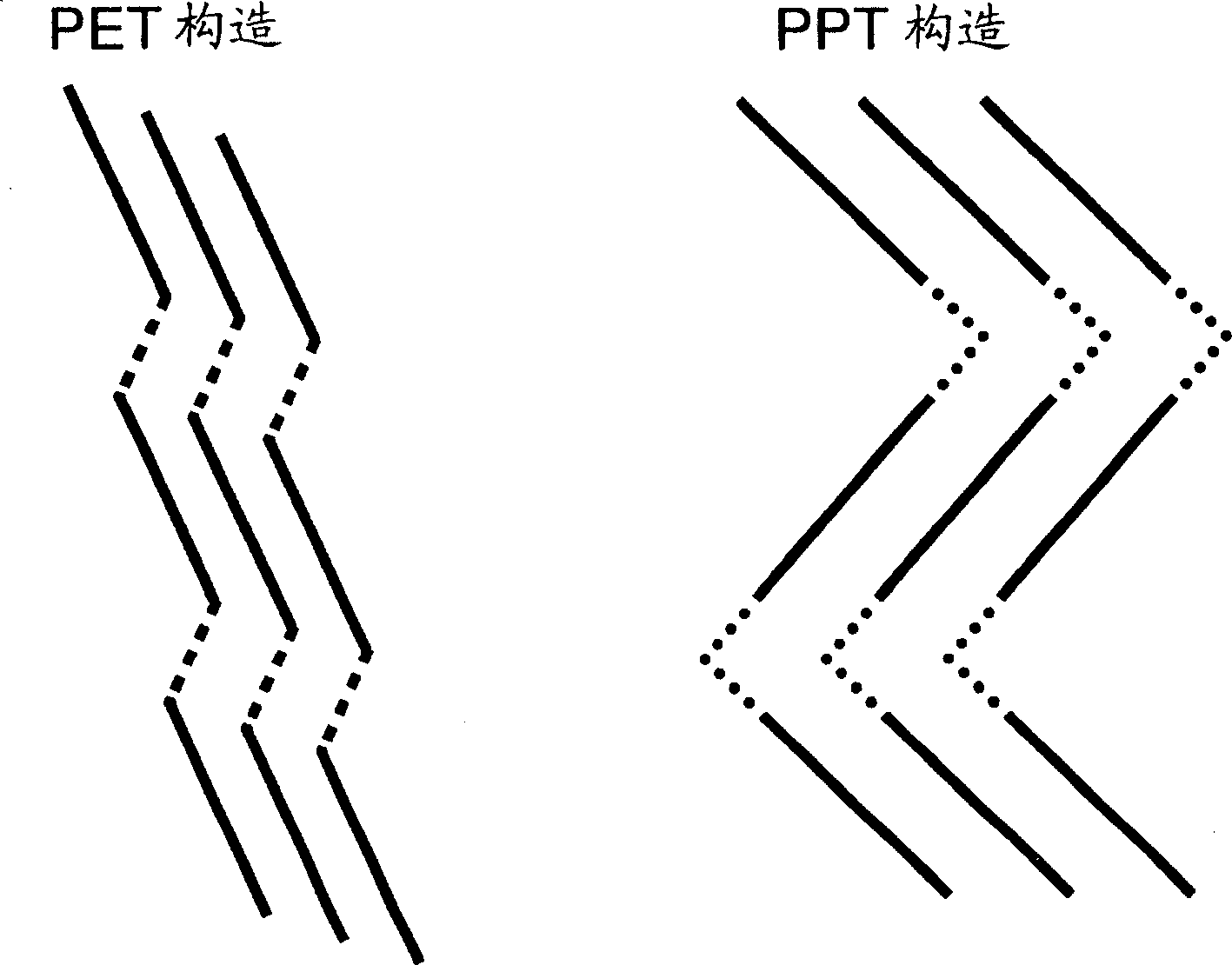

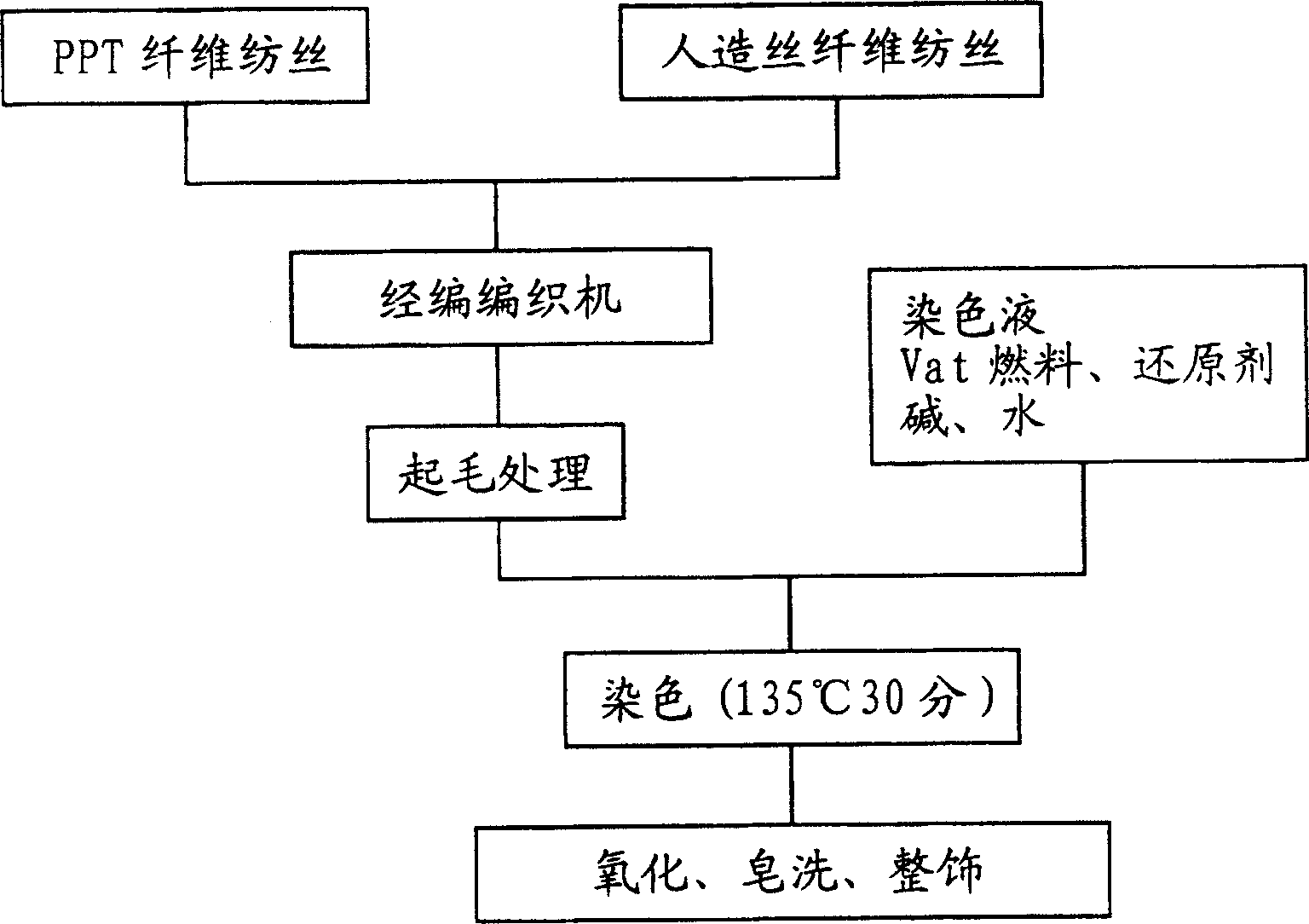

[0024] In the attached picture, figure 1 It is a partial cross-sectional view of a seat material for an automobile according to an embodiment of the present invention; figure 2 is an explanatory diagram schematically illustrating the difference in molecular structure between PPT and PET; image 3 It is a flow chart schematically showing an example of the manufacturing and dyeing process of the vehicle skin material.

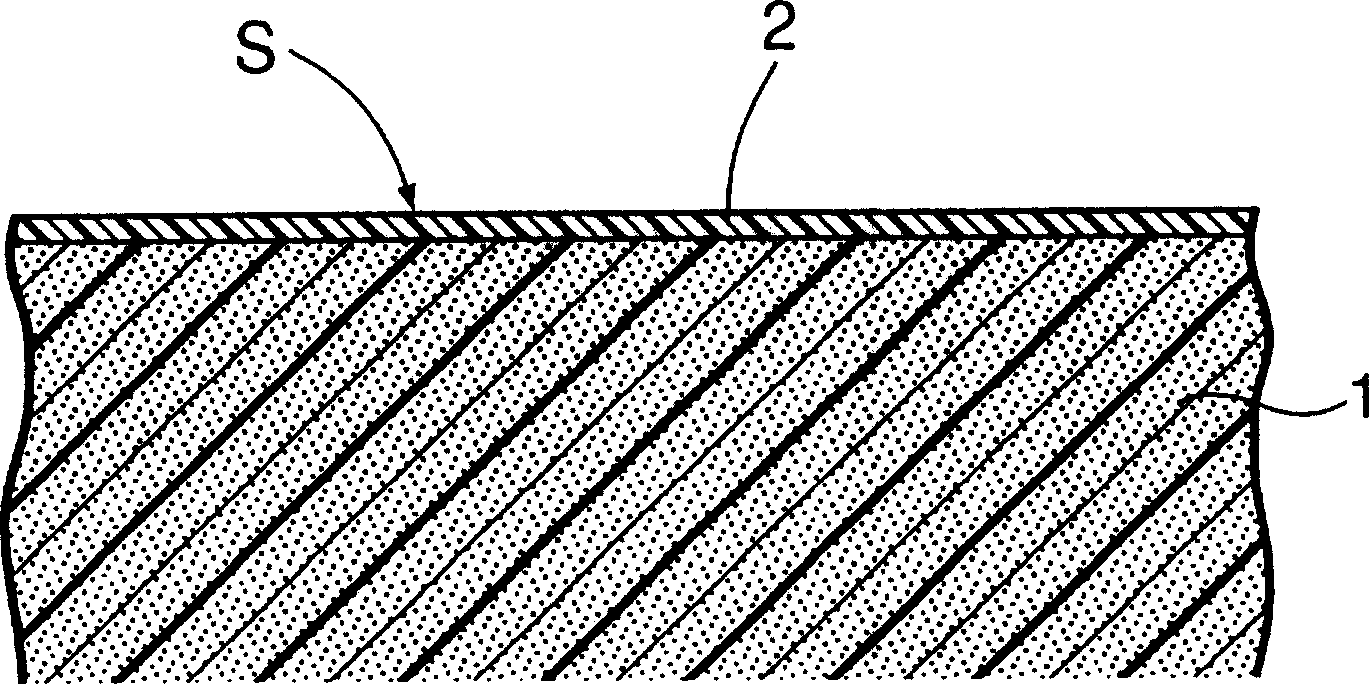

[0025] figure 1 Among them, the seat material S as an interior material for an automobile is composed of a cushioning body such as a sponge 1 and a cloth-like skin part 2 that covers the surface of the cushioning body 1 as a whole, and the vehicle skin of the present invention is used in the skin part 2 Material.

[0026] The skin material of the present embodiment is composed of a blended fabric of PPT (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com