Surface enhanced Raman spectrum substrate with nano gap and preparation method thereof

A nano-gap and substrate technology, applied in Raman scattering, nanotechnology, nanotechnology, etc., can solve the problems of cumbersome steps and cumbersome and complicated preparation methods, and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

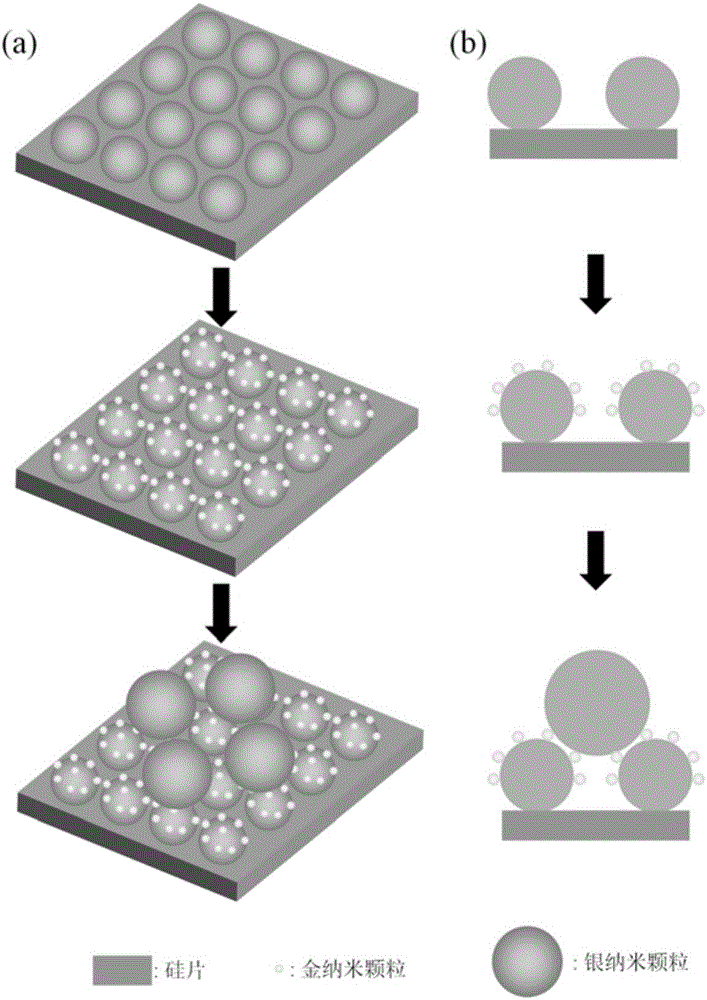

[0042] Example 1: Preparation of a SERS substrate with nano-gap

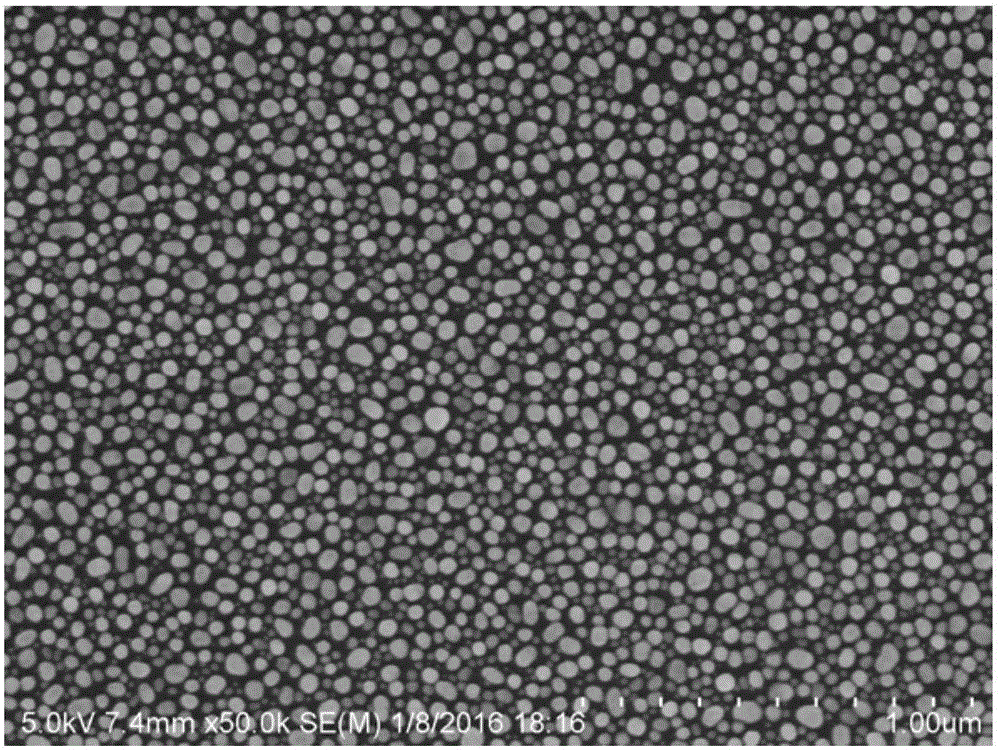

[0043]Preparation of the first layer of silver nanoparticles: Ultrasonic cleaning was performed on the monocrystalline silicon wafer using acetone, ethanol, and distilled water in sequence, and the ultrasonic cleaning time was 10 minutes each time. Soak the cleaned silicon chip in a mixed solution of silver nitrate and hydrofluoric acid for 10 seconds, wherein the concentration of silver nitrate in the mixed solution is 5 mmol / L, and the concentration of hydrofluoric acid is 4.8 mol / L. Among them, the silver nanoparticles on the silicon chip obtained are heated up from room temperature (about 20° C.) to 160° C. in a pure argon atmosphere for 30 minutes, and after being kept for 20 minutes, the temperature is naturally cooled to room temperature to obtain the silver nanoparticles attached to the single crystal silicon. The first layer of silver nanoparticles on the chip, the SEM picture is as follows figure 2 A...

Embodiment 2

[0051] Embodiment 2: Raman spectrum signal test of SERS substrate

[0052] The Raman spectrum signal intensity of the SERS substrate prepared in Comparative Example 1 and Comparative Example 1 was compared. The specific test method is as follows:

[0053] 4-Mercaptopyridine molecules are dissolved in ethanol, and the concentration of 4-Mercaptopyridine molecules is 1mmol / L. The substrate was immersed in the ethanol solution for 1 hour, and after being taken out, it was rinsed with ethanol, dried with nitrogen, and then detected by Raman spectroscopy. 4-mercaptopyridine can form a 4-mercaptopyridine monomolecular layer on the silver surface through a chemical reaction between the mercapto group and the silver atom on the substrate. The obtained SERS spectrum is as Figure 6 As shown, the experimental results show that: in the detection of 4-mercaptopyridine molecules at the same molar concentration, the SERS substrate of Example 1 showed a stronger Raman spectrum signal inte...

Embodiment 3

[0054] Example 3: Preparation of a SERS substrate with nano-gap

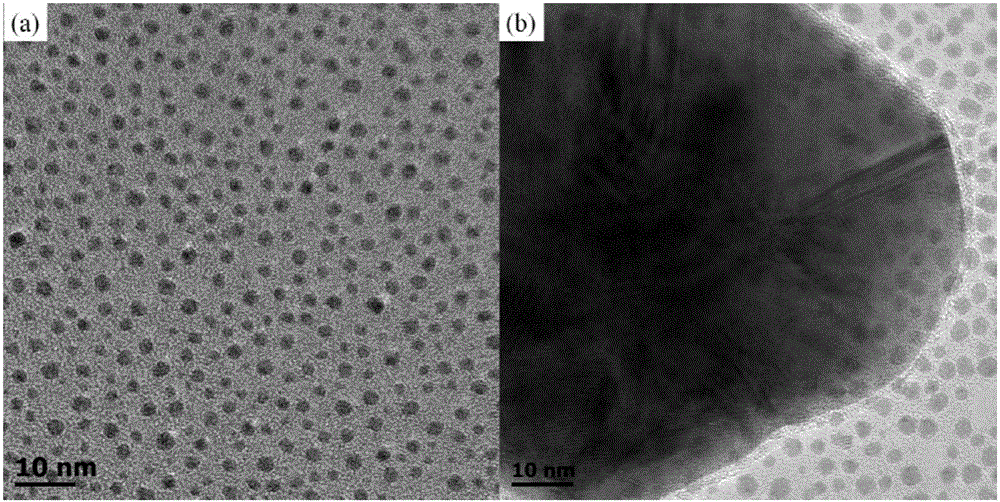

[0055] The method for preparing the first layer of silver nanoparticles is the same as in Example 1. The method for depositing gold nanoparticles is the same as in Example 1, wherein the sputtering time is 3s, and the TEM pictures of the sputtered gold nanoparticles and the sputtered gold nanoparticles to the first layer of silver nanoparticles are as follows Figure 7 a and Figure 7 As shown in b, the average diameter of the obtained gold nanoparticles is 2 nm. The method of preparing the silver nanoparticle dispersion solution is the same as in Example 1. The method of spin-coating the second layer of silver nanoparticles is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com