Abrasion-resistant valve seat

A valve seat and main body technology, which is applied in the direction of lift valves, engine components, machines/engines, etc., can solve problems such as not being widely used, ceramic material molding, and cutting processing difficulties, so as to achieve good product technical stability and improve service life , the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

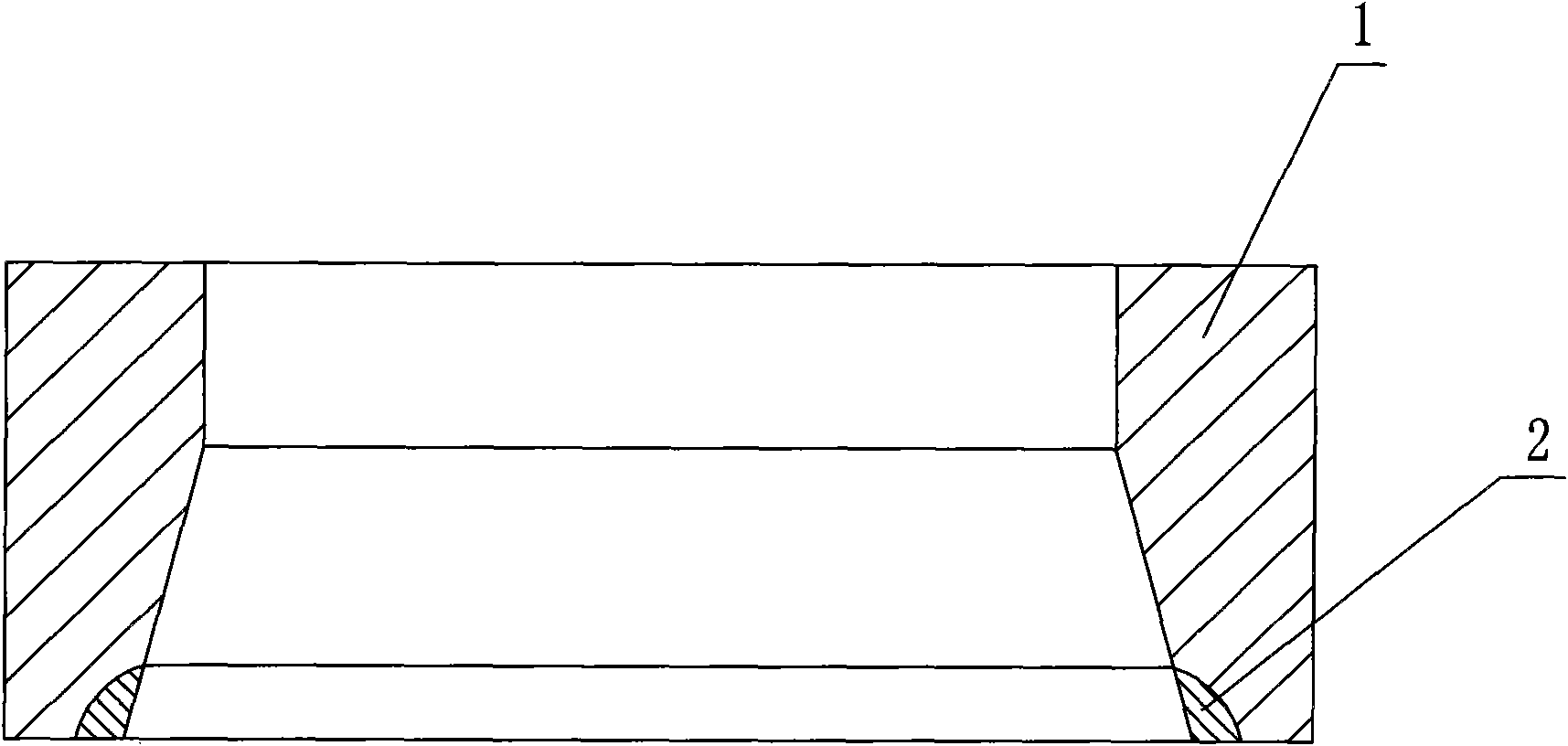

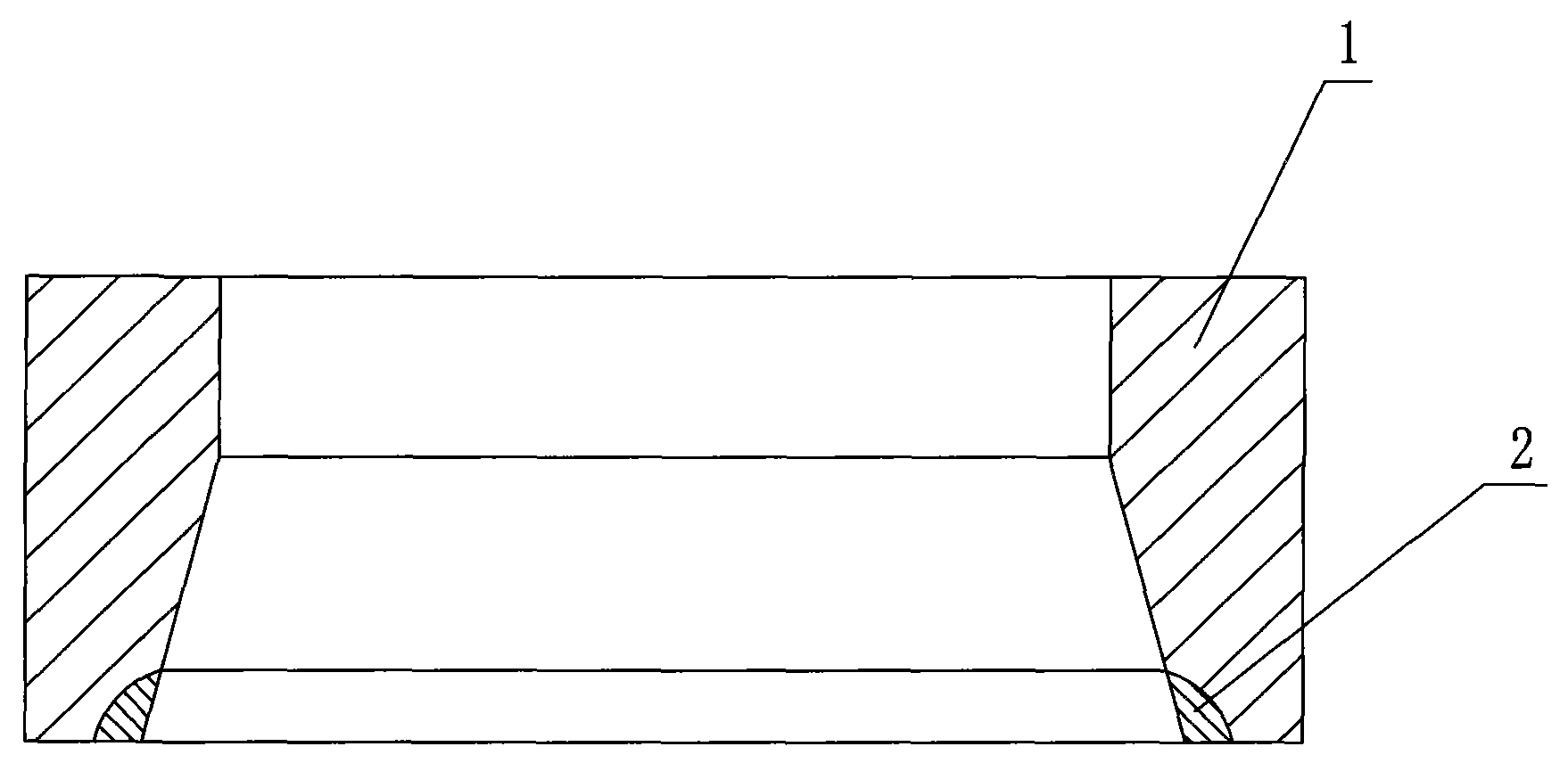

[0014] As shown in the figure, on the valve seat main body 1 obtained by casting the blank, grinding the end face, rough turning the outer circle, and rough boring the inner circle, the inner circle of the sealing cone surface matched with the valve is evenly coated with a layer of cermet Powder, using laser alloying method, forms ceramic particle reinforced composite coating 2 on the sealing cone surface of valve seat main body 1, its thickness is 0.5 ~ 1.0mm, and then the semi-finished product is finished turning the outer circle, fine boring inner circle, grinding Outer circle, outer corner chamfering, final inspection, and oiling to form the final piston ring.

[0015] The Rockwell hardness of the ceramic particle reinforced composite coating 2 of the present invention is 40-58HRC after testing, and the difference in weaving hardness of the composite coating of the same valve seat is not more than 3HRC units.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com