Aluminum alloy silver-plating pre-treatment method

A technology of aluminum alloy and degreasing treatment, applied in the field of aluminum alloy electroplating, can solve the problems of bubbling and peeling of the silver-plated layer, affecting normal use, etc., and achieve the effect of avoiding bubbling and peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

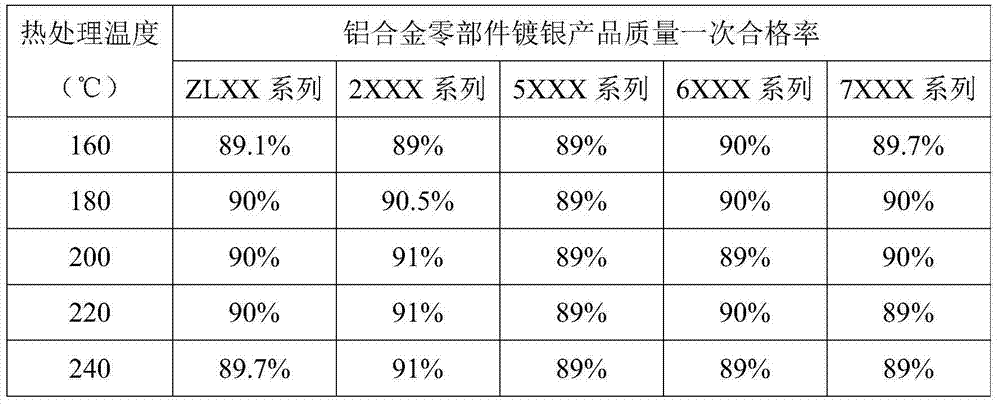

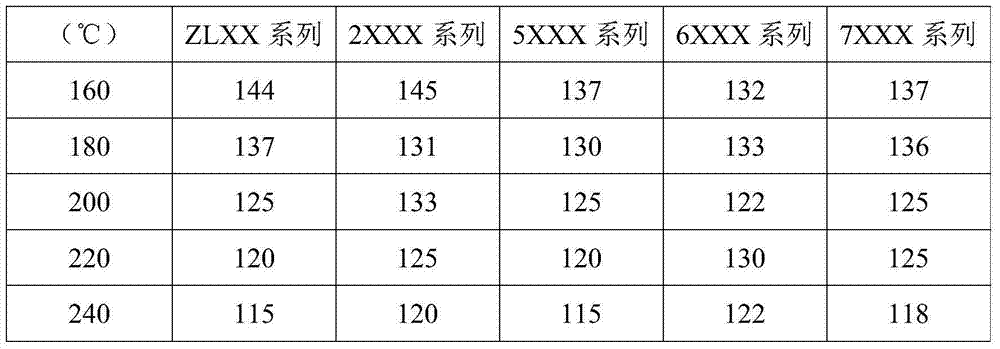

[0027] The method for pre-treatment of aluminum alloy silver plating in this embodiment includes first heat-treating the aluminum alloy to remove stress, and then performing surface treatment, specifically including the following steps:

[0028] 1) Heat treatment: Take ZLXX series aluminum alloy parts, heat them to 195°C in the atmosphere and keep them warm for 2 hours to remove stress;

[0029] 2) Degreasing and degreasing treatment: soak the parts after heat treatment in a degreasing agent, and in the degreasing agent, Na 2 CO 3 The concentration of 10g / L, Na 3 PO 4 12H 2 O concentration 15g / L, Na 2 SiO 3 The concentration of OP-10 emulsifier is 20g / L, the concentration of OP-10 emulsifier is 1.5g / L, and the balance is water; the soaking temperature is 60°C, and the time is 120s to remove the residual oil on the surface of parts;

[0030] 3) One-time water washing: wash the parts after degreasing and degreasing treatment at room temperature for 60s;

[0031] 4) Alkali...

Embodiment 2

[0037] The method for pre-treatment of aluminum alloy silver plating in this embodiment includes first heat-treating the aluminum alloy to remove stress, and then performing surface treatment, specifically including the following steps:

[0038] 1) Heat treatment: Take 2XXX series aluminum alloy parts, heat them to 205°C in the atmosphere and keep them warm for 2 hours to remove stress;

[0039] 2) Degreasing and degreasing treatment: soak the parts after heat treatment in a degreasing agent, and in the degreasing agent, Na 2 CO 3 The concentration of 12g / L, Na 3 PO 4 12H 2 O concentration 18g / L, Na 2 SiO 3 The concentration of OP-10 emulsifier is 15g / L, the concentration of OP-10 emulsifier is 2g / L, and the balance is water; the soaking temperature is 70°C, and the time is 20s to remove the residual oil on the surface of parts;

[0040] 3) One-time water washing: wash the parts after degreasing and degreasing treatment at room temperature for 120s;

[0041]4) Alkali et...

Embodiment 3

[0047] The method for pre-treatment of aluminum alloy silver plating in this embodiment includes first heat-treating the aluminum alloy to remove stress, and then performing surface treatment, specifically including the following steps:

[0048] 1) Heat treatment: Take 5XXX series aluminum alloy parts, heat them to 160°C in the atmosphere and keep them warm for 2 hours to remove stress;

[0049] 2) Degreasing and degreasing treatment: soak the parts after heat treatment in a degreasing agent, and in the degreasing agent, Na 2 CO 3 The concentration of 15g / L, Na 3 PO 4 12H 2 O concentration 20g / L, Na 2 SiO 3 The concentration of OP-10 emulsifier is 10g / L, the concentration of OP-10 emulsifier is 1g / L, and the balance is water; the soaking temperature is 65°C, and the time is 70s to remove the residual oil on the surface of parts;

[0050] 3) One-time water washing: wash the parts after degreasing and degreasing treatment at room temperature for 40s;

[0051] 4) Alkali et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com