High-performance surface mounting ink and preparation method thereof

A surface-mount, high-performance technology, applied in ink, household appliances, applications, etc., can solve problems that affect reliability, cannot realize automated production, and solder resist ink breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] (1) preparation of tetrabromobisphenol A type epoxy resin:

[0031] Add tetrabromobisphenol A, epichlorohydrin, and 80% isopropanol aqueous solution into the reactor, under nitrogen protection, stir until completely dissolved, then add dropwise 50% sodium hydroxide aqueous solution, The temperature is raised to 55°C, and the heat preservation reaction is carried out for 1 hour. The weight ratio is 1: 1.3: 3: 0.002; the temperature is raised to 65°C, and an aqueous sodium hydroxide solution with a mass fraction of 50% is added dropwise, and the heat preservation reaction is carried out for 1 hour. The tetrabromobisphenol A and the hydrogen with a mass fraction of 50% are The weight ratio of the sodium oxide aqueous solution is 1:0.002; the temperature is raised to 75° C., and the sodium hydroxide aqueous solution with a mass fraction of 50% is added dropwise, and the heat preservation reaction is carried out for 1 hour. The tetrabromobisphenol A and the hydrogen with a m...

Embodiment 1

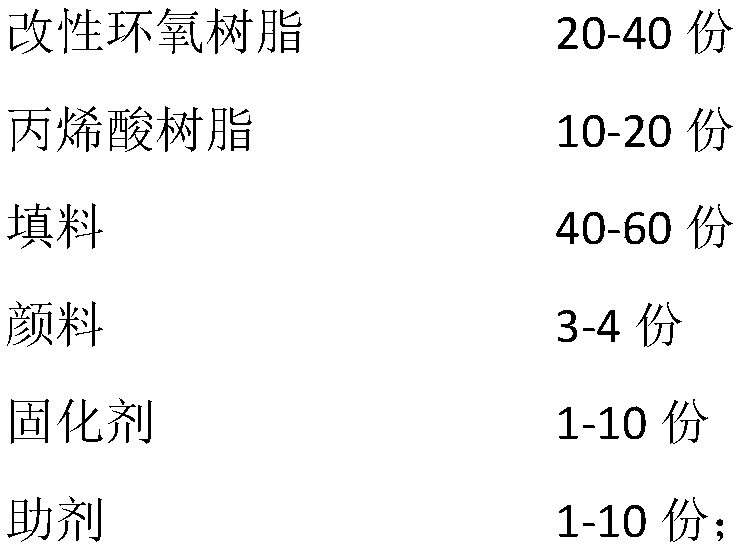

[0074] The high-performance surface mount ink, calculated in parts by weight, includes:

[0075]

[0076] Wherein, the auxiliary agent includes photosensitizer, dispersant, leveling agent, accelerator, diluent, defoamer, coupling agent, 0.3 parts of photosensitizer, 1 part of dispersant, 0.4 part of leveling agent, 1 part of accelerator part, 2 parts of thinner, 0.1 part of defoamer, 0.2 part of coupling agent; the modified epoxy resin is 4-benzamide-2-hydroxybenzoic acid modified tetrabromobisphenol A type epoxy resin; The raw materials for the preparation of the acrylic resin include cyclic olefin monomers, chain olefin monomers, and 3,4-dihydroxystyrene acid, and the cyclic olefin monomers are 5-vinylbicyclo[2.2.1]hept-2 -ene, the chain olefin monomer is 4,4-dimethyl-1-hexene; the filler is barium sulfate, modified talcum powder, modified kaolin; the barium sulfate and the modified talc powder, the weight ratio of the modified kaolin is 1:2:0.7; the pigment is cobalt bl...

Embodiment 2

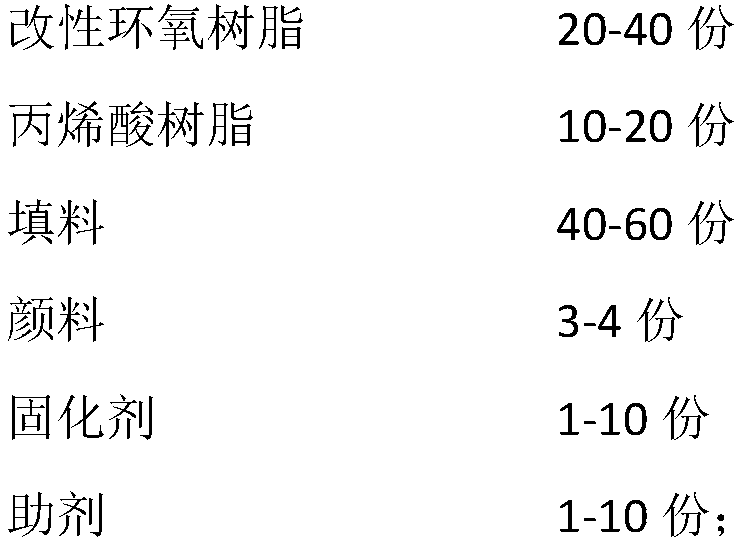

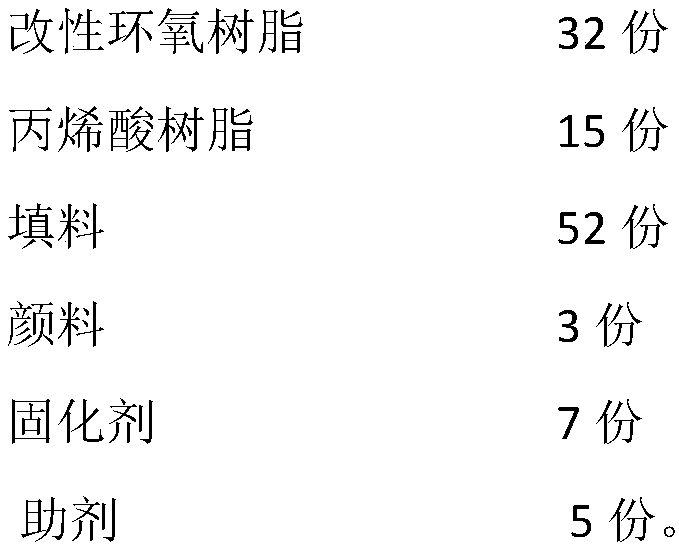

[0086] The high-performance surface mount ink, calculated in parts by weight, includes:

[0087]

[0088] Wherein, the auxiliary agent includes photosensitizer, dispersant, leveling agent, accelerator, diluent, defoamer, coupling agent, 0.3 parts of photosensitizer, 1 part of dispersant, 0.4 part of leveling agent, 1 part of accelerator part, 2 parts of thinner, 0.1 part of defoamer, 0.2 part of coupling agent; the modified epoxy resin is 4-benzamide-2-hydroxybenzoic acid modified tetrabromobisphenol A type epoxy resin; The raw materials for the preparation of the acrylic resin include cyclic olefin monomers, chain olefin monomers, and 3,4-dihydroxystyrene acid, and the cyclic olefin monomers are 5-vinylbicyclo[2.2.1]hept-2 -ene, the chain olefin monomer is 4,4-dimethyl-1-hexene; the filler is barium sulfate, modified talcum powder, modified kaolin; the barium sulfate and the modified talc powder, the weight ratio of the modified kaolin is 1:2:0.7; the pigment is cobalt bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com