Resonator structure design for high-performance surface acoustic wave filter

A surface acoustic wave and structural design technology, applied in the direction of instruments, calculations, special data processing applications, etc., to achieve the effects of structural optimization design suppression, high electromechanical coupling coefficient, and good frequency and temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

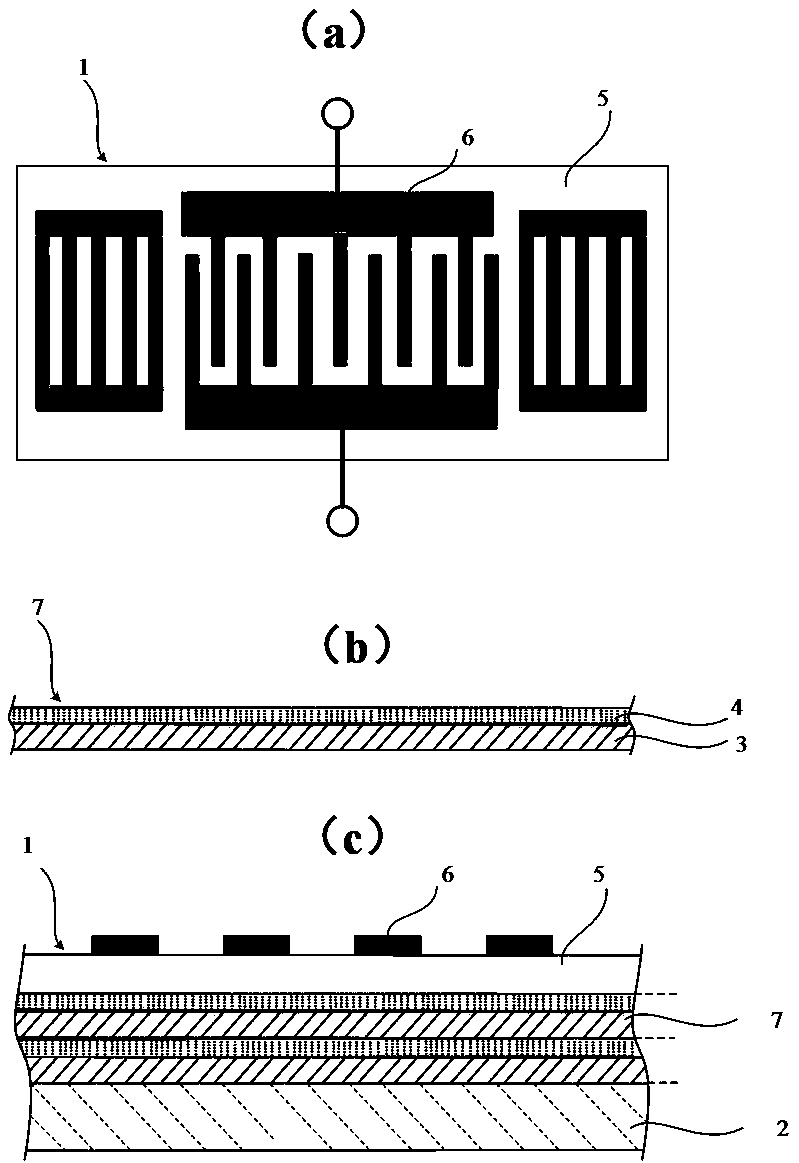

[0032] A resonator structure (1) for high-performance SAW filters, such as figure 1 (c), using single crystal Si substrate (2), multilayer thin film structure (7), YX-θ LiTaO 3 The piezoelectric film (5), the interdigitated electrode IDT mainly composed of Cu electrodes, the reflective grid (6) and the like are stacked and arranged sequentially from bottom to top. The multi-layer film structure (7) is formed by alternately depositing high acoustic impedance films (3) and low acoustic impedance films (4), such as figure 1 (b) shown.

[0033] In this embodiment, the thickness of the single crystal Si substrate is greater than or equal to 2 lambda , the thickness of high acoustic impedance film and low acoustic impedance film is 0.25 lambda AlN and SiO 2 film. YX-θ LiTaO 3 The piezoelectric film thickness is 0.2 lambda, the Euler angle is θ=42 o , the electrode thickness range is 0.01 lambda ~0.08 lambda .

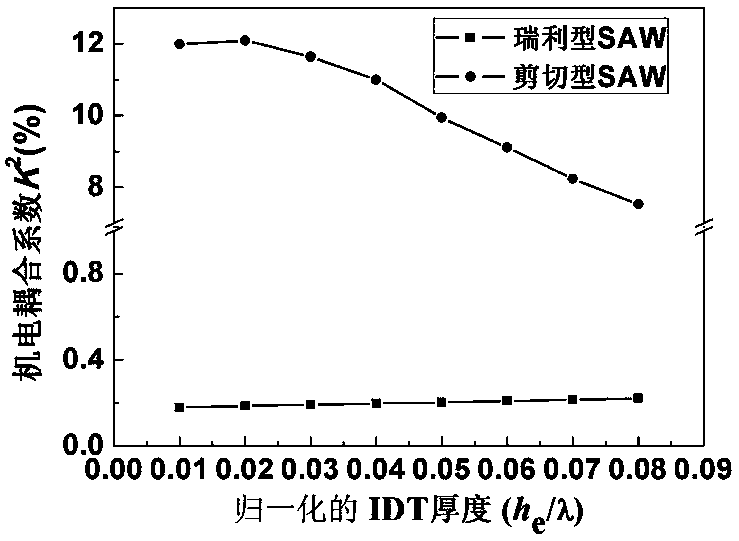

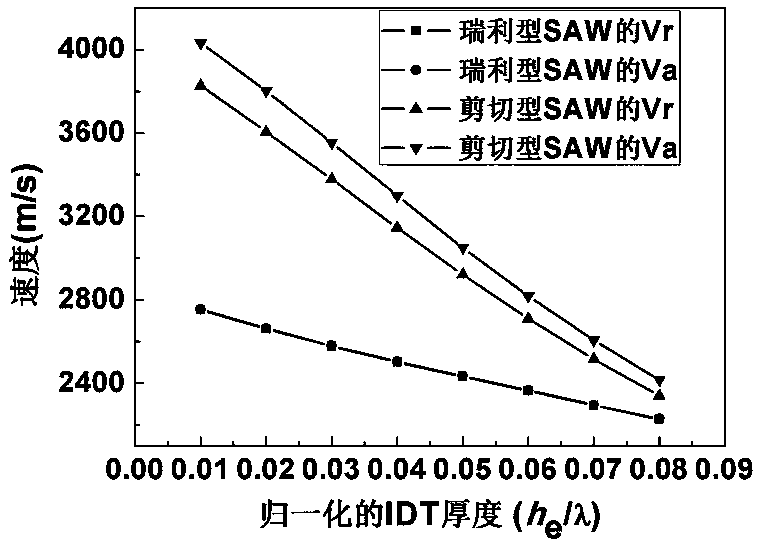

[0034] figure 2 and image 3 Respectively, the electrome...

Embodiment 2

[0036] In this embodiment, the electrode thickness is 0.02 lambda , YX-θ LiTaO 3 The piezoelectric film thickness range is 0.1 lambda ~2 lambda , all the other are with embodiment 1.

[0037] Figure 4 and Figure 5 Respectively, the surface acoustic wave resonator structure in this embodiment is in different YX-θ LiTaO 3 Electromechanical coupling coefficients and phase velocity curves at resonance and antiresonance for the next-order Rayleigh wave and second-order horizontal shear wave through the thickness of the piezoelectric film. Such as Figure 4 As shown in , the electromechanical coupling coefficient of the horizontal shear wave first increases and then decreases with the increase of the film thickness. In YX-θ LiTaO 3 The piezoelectric film thickness is 0.2 lambda When , the maximum value of the electromechanical coupling coefficient is 12%. However, the electromechanical coupling coefficient of the Rayleigh wave is very small (less than 0.17%) and increases...

Embodiment 3

[0039] In this embodiment, the electrode thickness is 0.02 lambda , YX-θ LiTaO 3 The piezoelectric film thickness range is 0.2 lambda , the Euler angle is θ and the range is 0 o ~180 o , all the other are with embodiment 1.

[0040] Figure 6 and Figure 7 Respectively, the electromechanical coupling coefficients of the SAW resonator structure in this embodiment at different Euler angles θ for the next-order Rayleigh wave and the second-order horizontal shear wave, and the phase velocity curves at resonance and anti-resonance. Such as Figure 6 As shown in , when the Euler angle θ is at 0 o ~60 o Inside, the electromechanical coupling coefficient of the horizontal shear wave is 8.7%~12%; the Euler angle is 25 o When , the electromechanical coupling coefficient takes the largest value: 13.2%; the Euler angle is 120 o , the electromechanical coupling coefficient is almost zero. The electromechanical coupling coefficient of the Rayleigh wave first increases and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com