Solid-state connection method of surface self-nanocrystallization TC17 alloy and TC4 alloy

A TC17, self-nanotechnology technology, used in welding equipment, metal processing equipment, non-electric welding equipment and other directions, can solve the problems of long connection time, long manufacturing cycle, increased energy consumption during connection time and other problems, and achieves dense organization without defects, The effect of promoting metallurgical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of solid-state connection method of surface self-nanometerized TC17 alloy and TC4 alloy, comprising the following steps:

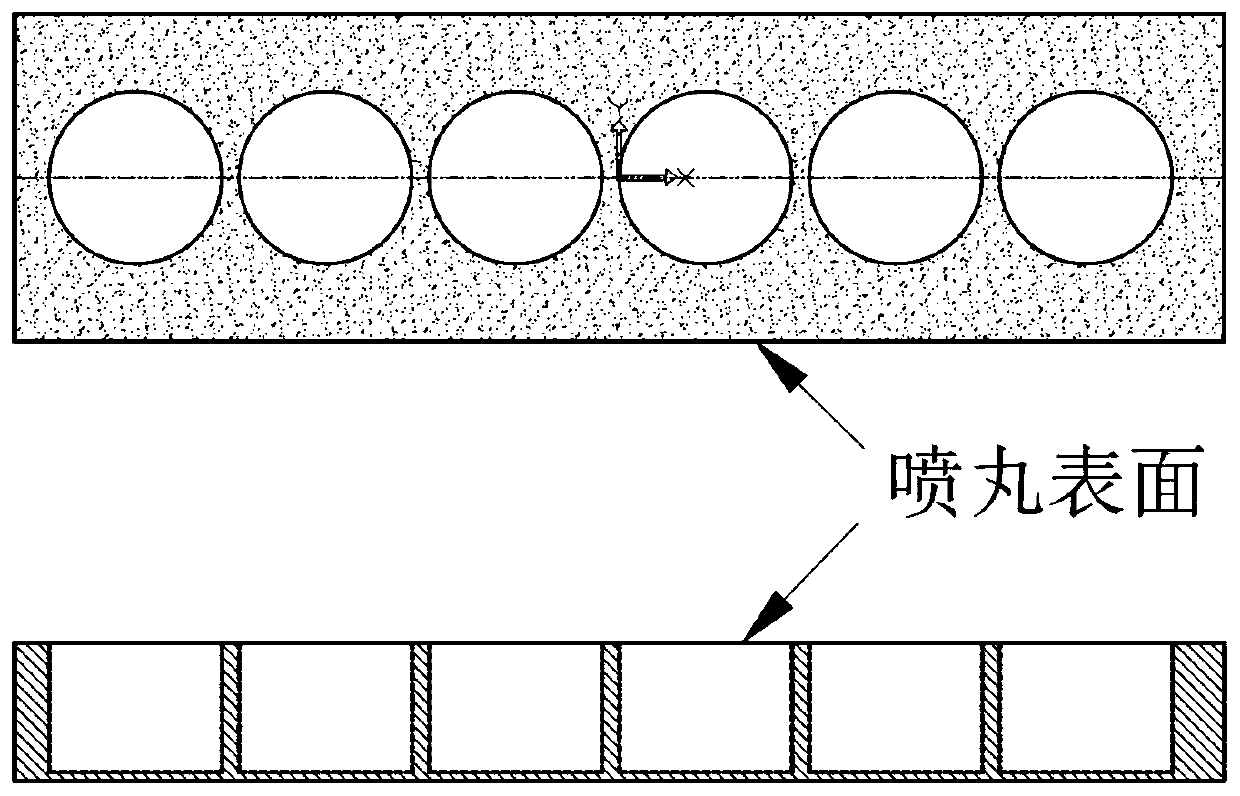

[0027] (1) TC17 alloy is put into the shot blasting chamber, and the spray gun is adjusted apart from TC17 alloy 250-350mm, adopting the cast steel projectile that diameter size is 0.5-0.7mm carries out shot blasting to the surface of TC17 alloy; The air pressure is 0.25-0.45MPa, and the shot peening time is 20-60min;

[0028] (2) Put the TC17 alloy after shot blasting into absolute ethanol solution and carry out ultrasonic cleaning for 15-25min, then dry it with a blower for subsequent use;

[0029] (3) Use 180#, 240#, 400#, 600#, 800#, 1000#, 1200#, 1500# SiC water sandpaper to grind the TC4 alloy step by step; then, grind the TC4 alloy Put it in absolute ethanol solution for ultrasonic cleaning for 15-25min, then dry it with a hair dryer for later use;

[0030] (4) The shot peening surface of the TC17 alloy is closely attac...

Embodiment 2

[0032] Embodiment 2: the same as Embodiment 1, the difference is: the specific steps of this embodiment include the following steps:

[0033] (1) Put the TC17 alloy into the shot blasting chamber, and adjust the distance of the spray gun to 300mm from the TC17 alloy, and use cast steel projectiles with a size of Ф0.6mm to perform shot peening on the surface of the TC17 alloy. The specific shot peening process parameters are: the air pressure is 0.45MPa, shot peening time is 60min;

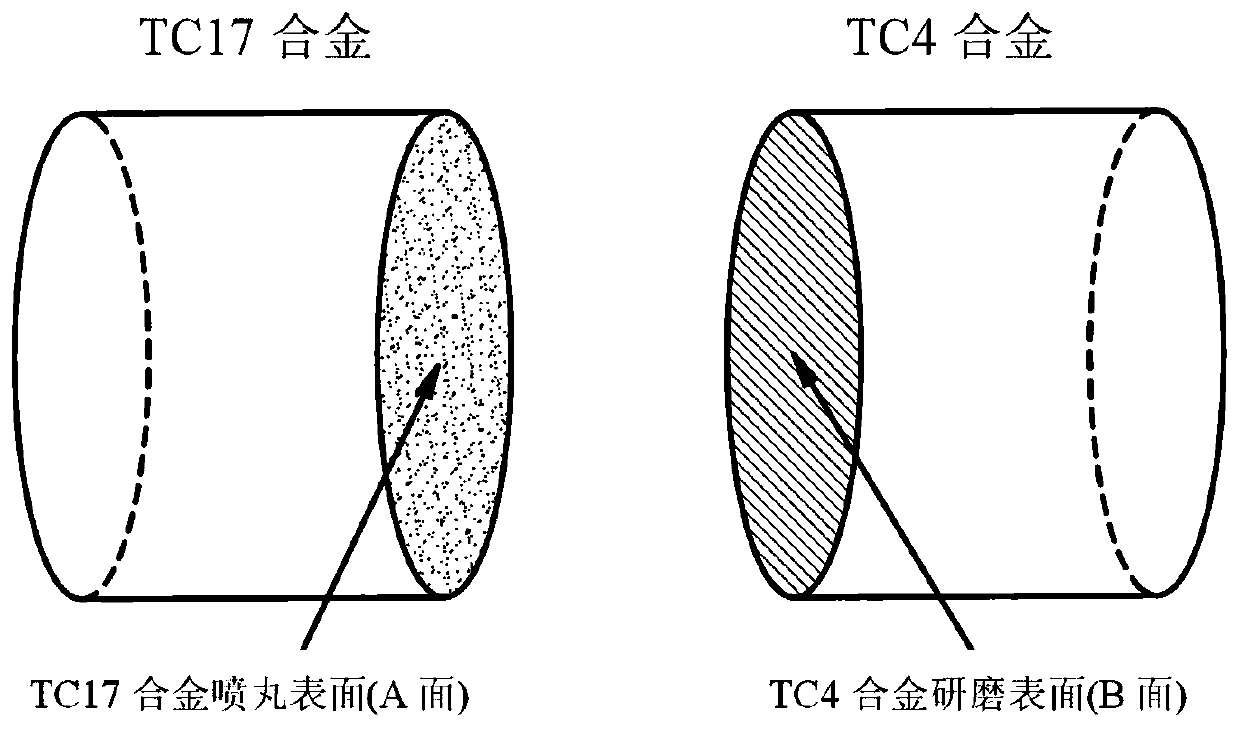

[0034] (2) Process the shot-peened TC17 alloy into a connection specimen: in figure 1 A rectangular parallelepiped TC17 alloy is shown in , on which the connecting specimen is processed, specifically, a cylindrical TC17 alloy connecting specimen with a size of Ф10mm×7.5mm is processed along the centerline of the rectangular parallelepiped TC17 alloy; it is a circular specimen of Ф10mm The shot blasting surface of TC17 alloy is reserved on the surface of the connection test piece;

[0035] (3) Put...

Embodiment 3

[0041] Embodiment 3: the same as Embodiment 2, the difference is: in step (7), the temperature is raised to 820° C. at a rate of 2° C. s −1 .

[0042] According to the steps of the above-mentioned embodiments, the solid-state connection between the surface self-nanoized TC17 alloy and the TC4 alloy can be realized. Depend on Image 6 It can be seen that the connection joints are well bonded, and the joint tissue is dense without obvious defects. After testing, the room temperature shear strength of the connection joint is 789MPa, which is higher than the room temperature shear strength of the TC4 alloy base material (720MPa).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com