Method for preparing high-performance surface acoustic wave device with multilayer film structure

A surface acoustic wave device, multi-layer film technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the problems of inability to withstand high power, unstable product quality, unfavorable promotion and application, etc. It is conducive to large-scale popularization and application, significant production practical significance, and convenient and easy process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

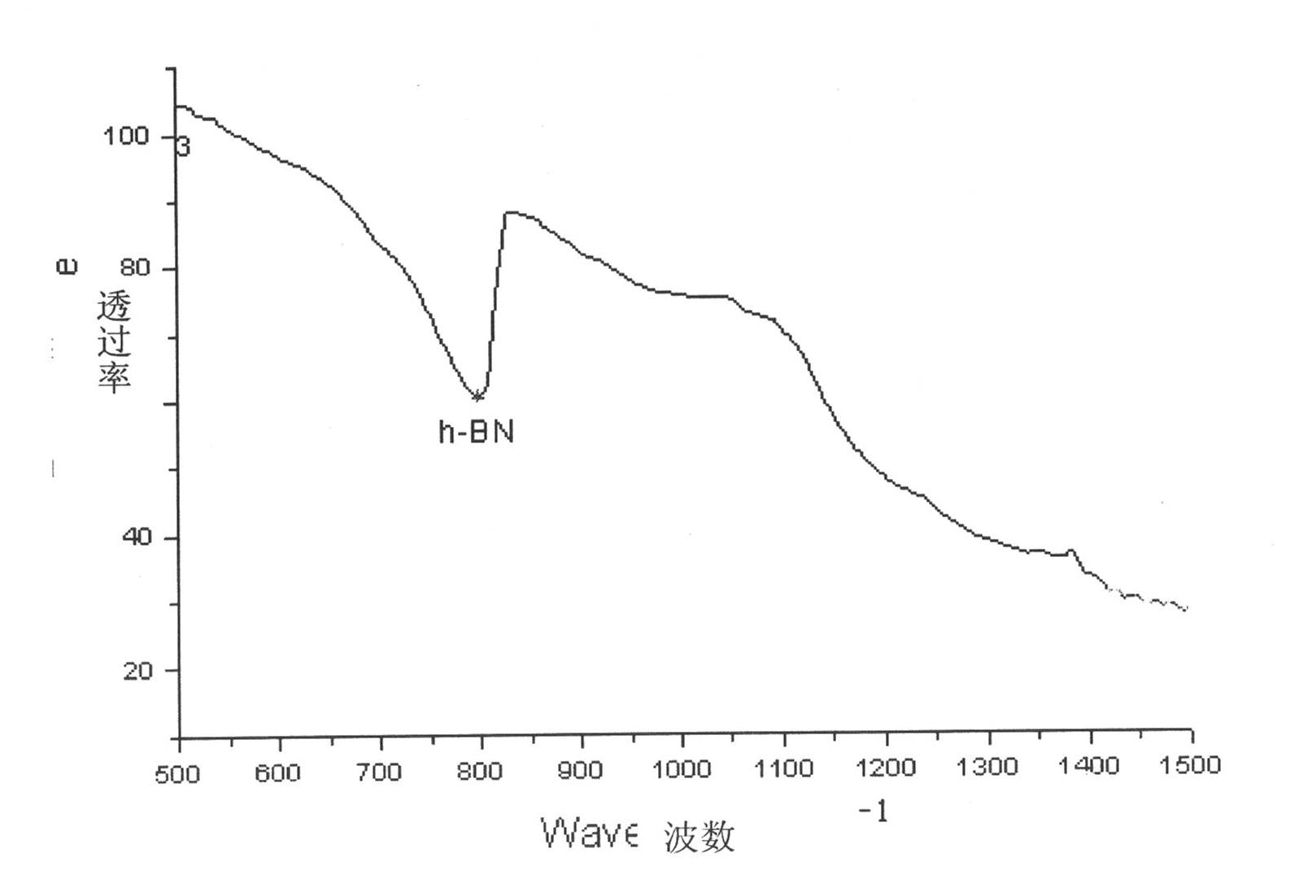

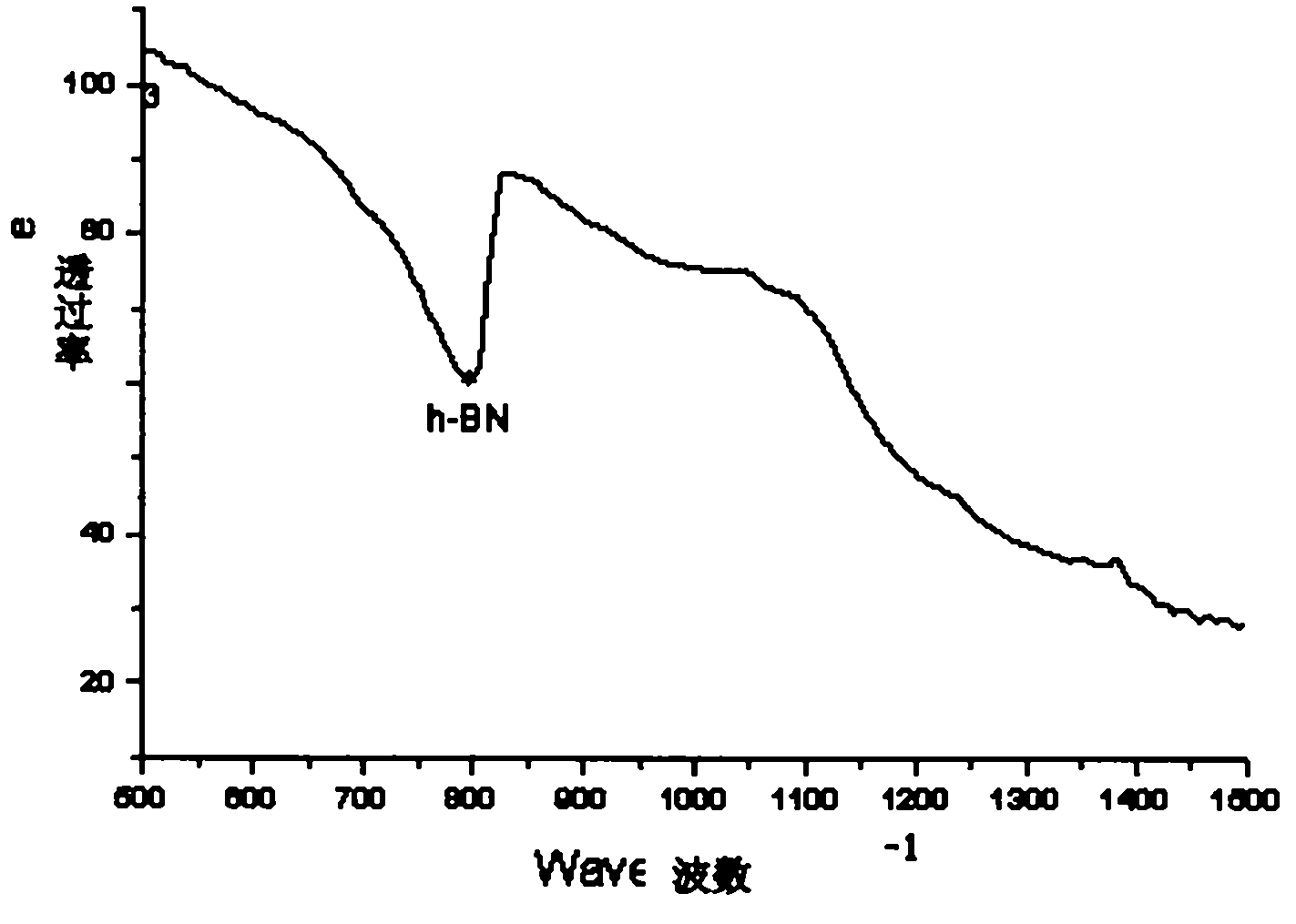

[0020] Firstly, a high-performance multilayer thin-film structure surface acoustic wave device is prepared according to the existing technology, that is, a layer of h-BN film is formed by sputtering on the surface of the CVD diamond film, and finally a high-performance multilayer thin-film structure surface acoustic wave device is obtained, specifically including The following steps:

[0021] 1) polishing the surface of the chemical vapor deposition CVD diamond film to form a mirror-polished CVD diamond film surface, the preparation steps are:

[0022] First, on a mirror-polished silicon substrate, in a mixed atmosphere composed of argon, hydrogen, and methane, the volume ratio between the argon, hydrogen, and methane is 70%:27%:3%, and in the deposition chamber , the microwave power is 5000W, the deposition chamber pressure is 80 Torr, the mixed gas flow rate is 600sccm (milliliters per minute) and the substrate temperature is 750°C, and the chemical vapor deposition is carri...

Embodiment 2

[0040] The steps of preparing a high-performance multilayer thin film structure surface acoustic wave device according to the prior art are the same as those in Example 1.

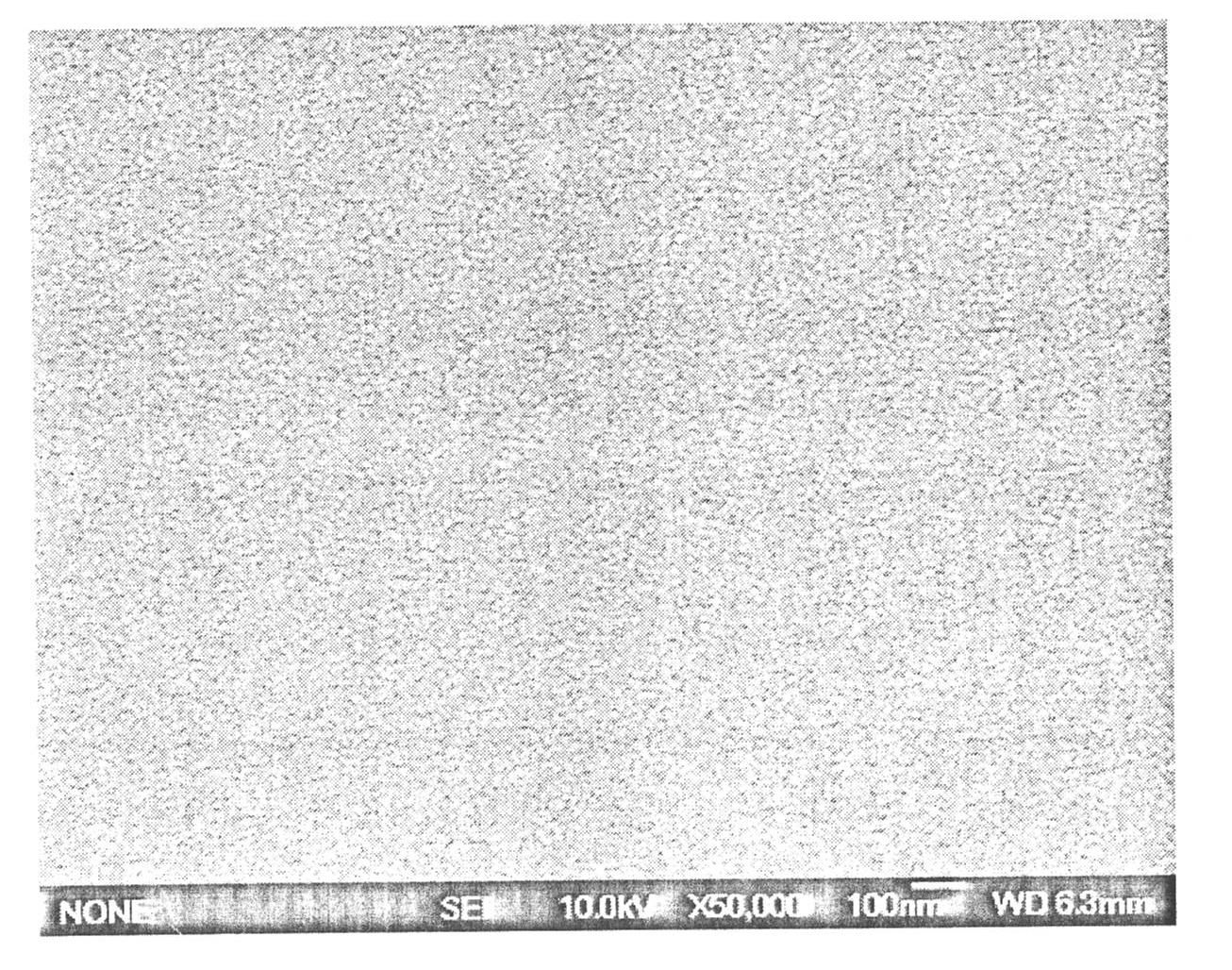

[0041] In this embodiment, a layer of h-BN film was sputtered on the surface of the mirror-polished and hydrogen-terminated CVD diamond film using an ultra-high vacuum radio frequency magnetron sputtering system. The sputtering power used was 230W, and the substrate temperature was The temperature is 400°C, the working pressure is 1.1Pa, the mass flow ratio between argon and nitrogen is 20:4, and it is prepared by the following steps:

[0042] 1) Depositing a B-rich boron nitride bottom layer. During the sputtering process, the working gas in the vacuum sputtering chamber is a mixed gas of argon and nitrogen, the flow rate of argon gas is fixed at 20 sccm, and the flow rate of nitrogen gas is increased from 1 sccm to 4 sccm, and the step increment value is 1 sccm per step, argon gas and nitrogen gas The v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com