Guerbet anion surfactant, and its preparing method and use

A technology of surfactants and anions, applied in the direction of surface active detergent compositions, chemical instruments and methods, transportation and packaging, etc., can solve problems such as Guerbet anionic surfactants not mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

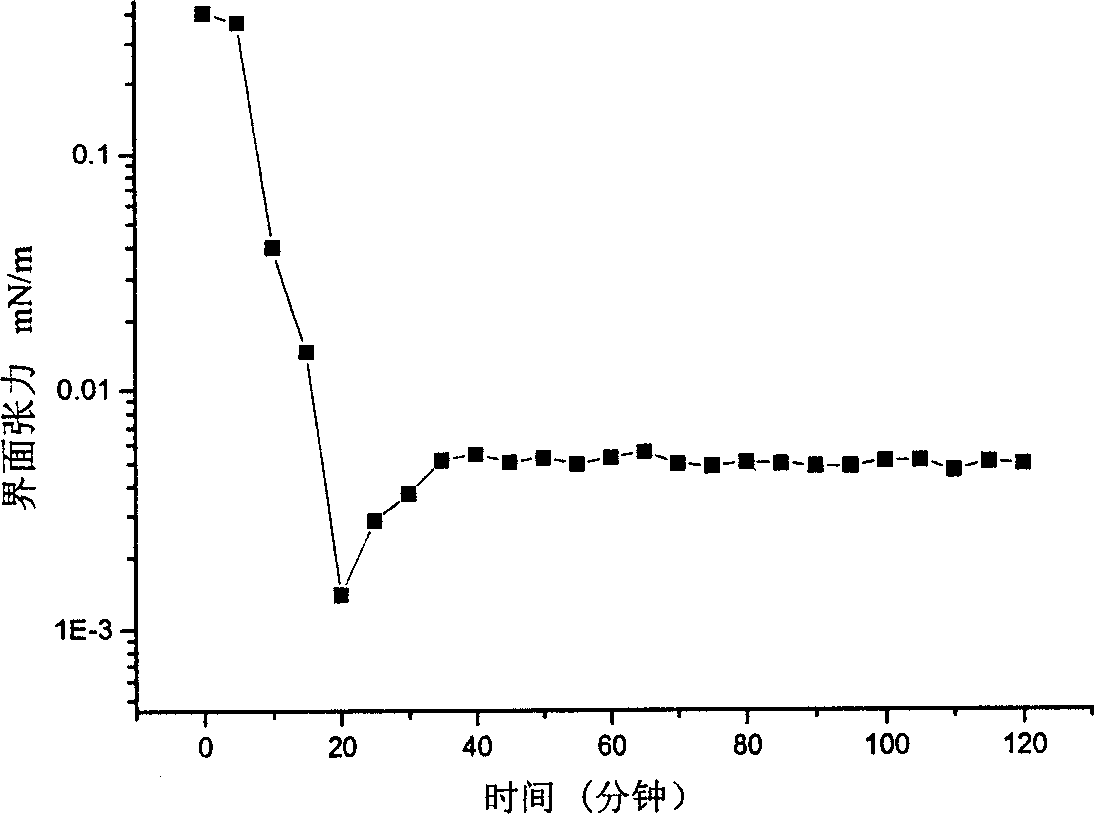

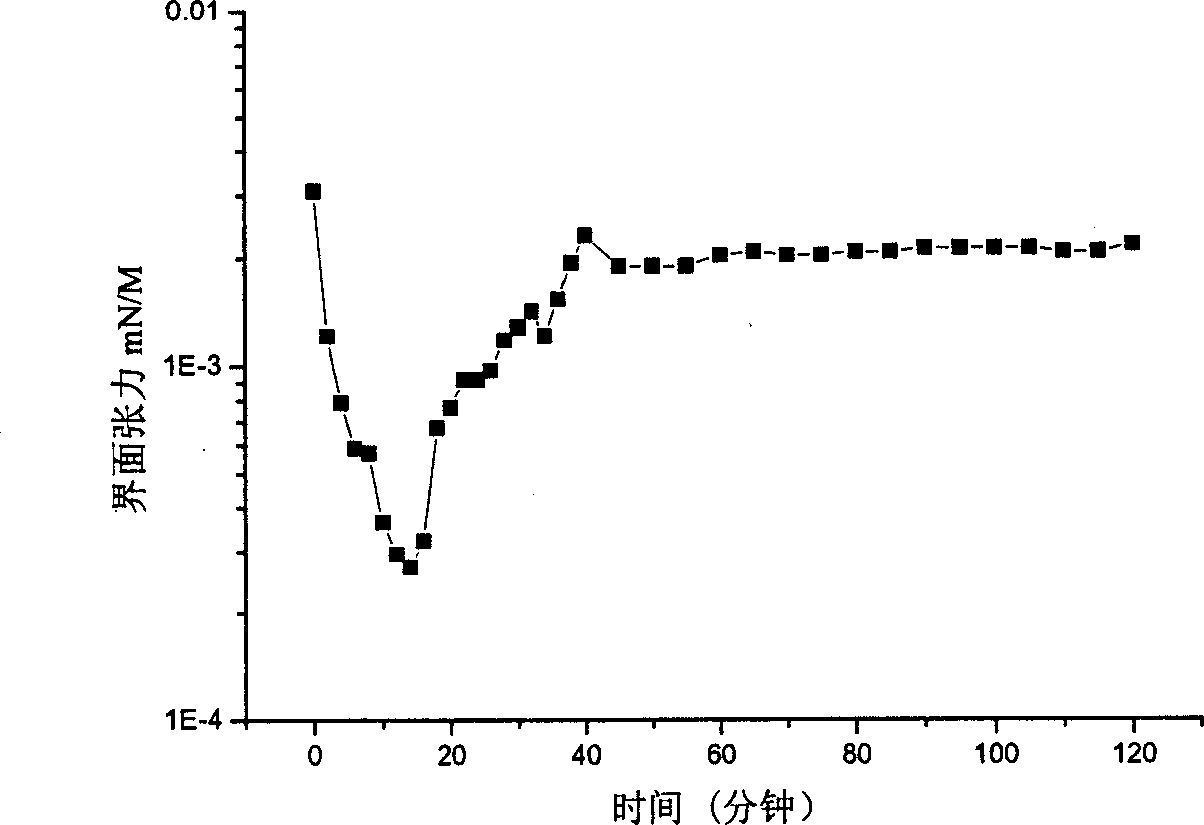

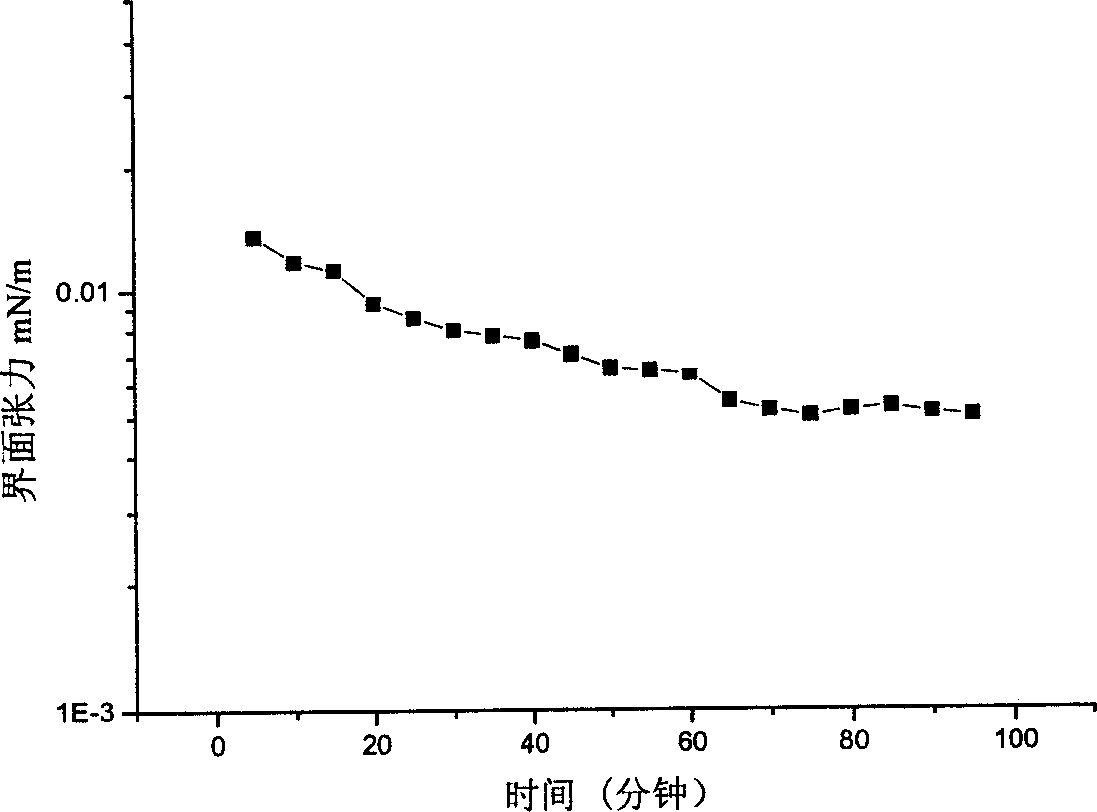

Image

Examples

Embodiment 1

[0051] Embodiment 1: Preparation of Guerbet tetradecyl alcohol polyoxyethylene ether sodium sulfonate

[0052] (a) Bromination of Guerbet Tetradecyl Alcohol

[0053] In the 250 milliliters three-neck flasks that oil bath, reflux condenser and stirrer are installed, add hydrobromic acid and concentrated sulfuric acid, then drop into Guerbet Tetradecyl Alcohol to form reaction system; Wherein the reaction system contains 0.4 mole of Hydrobromic acid, 0.2 mole of concentrated sulfuric acid, 0.25 mole of Guerbet tetradecyl alcohol; heating and reflux for 7 hours, after cooling, the reaction mixture was washed with water, the organic phase was separated, and then water and a concentration of 5wt% sodium carbonate aqueous solution Wash the organic phase. Then dry with anhydrous calcium chloride. After filtering, the filtrate was distilled under reduced pressure, and fractions were collected under the condition of temperature of 170°C and pressure of 2.4kPa. The product is Guerbet...

Embodiment 2

[0059] Embodiment 2: Preparation of Guerbet tetradecyl polyoxyethylene ether carboxylate sodium

[0060] (a) Bromination of Guerbet Tetradecyl Alcohol

[0061] In the 250 milliliters three-neck flasks that oil bath, reflux condenser and stirrer are installed, add hydrobromic acid and concentrated sulfuric acid, then drop into Guerbet Tetradecyl Alcohol to form reaction system; Wherein the reaction system contains 0.4 mole of Hydrobromic acid, 0.2 mole of concentrated sulfuric acid, 0.25 mole of Guerbet tetradecyl alcohol; heating and reflux for 7 hours, after cooling, the reaction mixture was washed with water, the organic phase was separated, and then water and a concentration of 5wt% sodium carbonate aqueous solution Wash the organic phase. Then dry with anhydrous calcium chloride. After filtering, the filtrate was distilled under reduced pressure, and fractions were collected at a temperature of 150° C. and a pressure of 2.4 kPa. The product is Guerbet tetradecyl bromide...

Embodiment 3

[0067] The synthesis of embodiment 3 Guerbet tetradecyl polyoxyethylene ether sulfate sodium

[0068] (a) Bromination of Guerbet Tetradecyl Alcohol

[0069] In the 250 milliliters three-neck flasks that oil bath, reflux condenser and stirrer are installed, add hydrobromic acid and concentrated sulfuric acid, then drop into Guerbet Tetradecyl Alcohol to form reaction system; Wherein the reaction system contains 0.4 mole of Hydrobromic acid, 0.2 mole of concentrated sulfuric acid, 0.25 mole of Guerbet tetradecyl alcohol; heating and reflux for 7 hours, after cooling, the reaction mixture was washed with water, the organic phase was separated, and then water and a concentration of 5wt% sodium carbonate aqueous solution Wash the organic phase. Then dry with anhydrous calcium chloride. After filtering, the filtrate was distilled under reduced pressure, and fractions were collected at a temperature of 150° C. and a pressure of 2.4 kPa. The product is Guerbet tetradecyl bromide. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com