Method for preparing cubic silicon carbide crystals and device thereof

A cubic silicon carbide, silicon carbide technology, applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve problems such as the inability to effectively prepare cubic silicon carbide, achieve stable preparation, maintain growth rate, and increase crystal growth. The effect of growing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

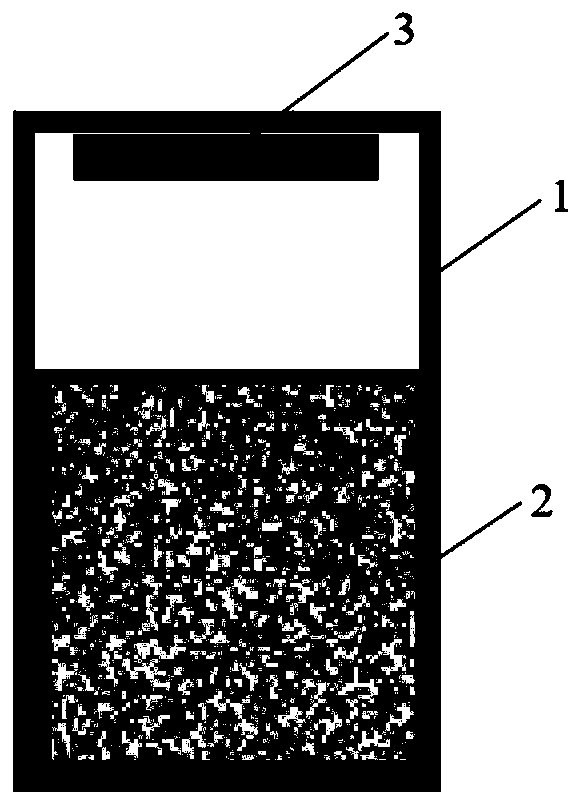

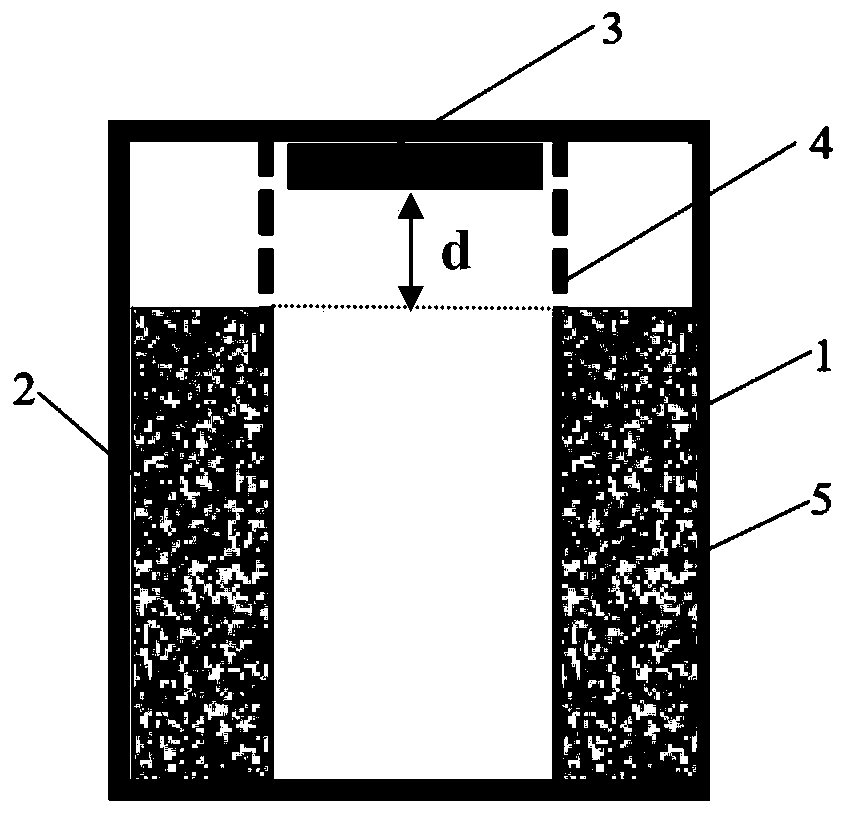

[0035] Embodiment 1 provides a method for preparing cubic silicon carbide crystals, placing silicon carbide powder 2 and seed crystal 3 in a closed graphite crucible 1, wherein the seed crystal 3 is placed at the top center of the graphite crucible 1 , the silicon carbide powder 2 is placed outside the seed crystal 3, and a graphite ring is used to isolate the silicon carbide powder 2 from the seed crystal 3, and the growth temperature of 1800°C and the growth pressure of 1500Pa are used to sublimate the silicon carbide powder 2 to the surface of the seed crystal 3, and cooling and crystallizing on the seed crystal 3 to grow cubic silicon carbide crystals.

[0036] Wherein, the graphite ring is composed of porous graphite at the upper end and dense graphite 5 at the lower end, and the vertical distance between the lower surface of the seed crystal and the top of the dense graphite is 1 mm.

Embodiment 2

[0038] The process of embodiment 2 is basically the same as that of embodiment 1, except that the vertical distance between the lower surface of the seed crystal and the top of the dense graphite in embodiment 2 is 5 mm.

Embodiment 3

[0040] The process of embodiment 3 is basically the same as that of embodiment 1, except that the vertical distance between the lower surface of the seed crystal and the top of the dense graphite in embodiment 3 is 10 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com