Method for production of silicon carbide layer, gallium nitride semiconductor device and silicon substrate

A silicon carbide layer and silicon substrate technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of inability to form a group III nitride semiconductor layer and a non-silicon carbide layer, and achieve excellent crystallinity, The effect of suppressing ionization and preventing deterioration of crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Cubic silicon carbide crystalline layers, in particular 3C-silicon carbide layers (SiC layers) according to the Ramsdell notation, can be formed as silicon substrates having surfaces with different crystallographic planes, (cf. "Electric Refractory Materials", Marcel Decker, Inc. ., 2000, pp.409-411). To form a 3C-SiC layer oriented in the [001] direction, it is advantageous to use (001) silicon having a (001) crystal plane as its surface as a substrate. To form a 3C-SiC layer oriented in the [111] direction, (111) silicon having a (111) crystal plane as its surface is used as a substrate.

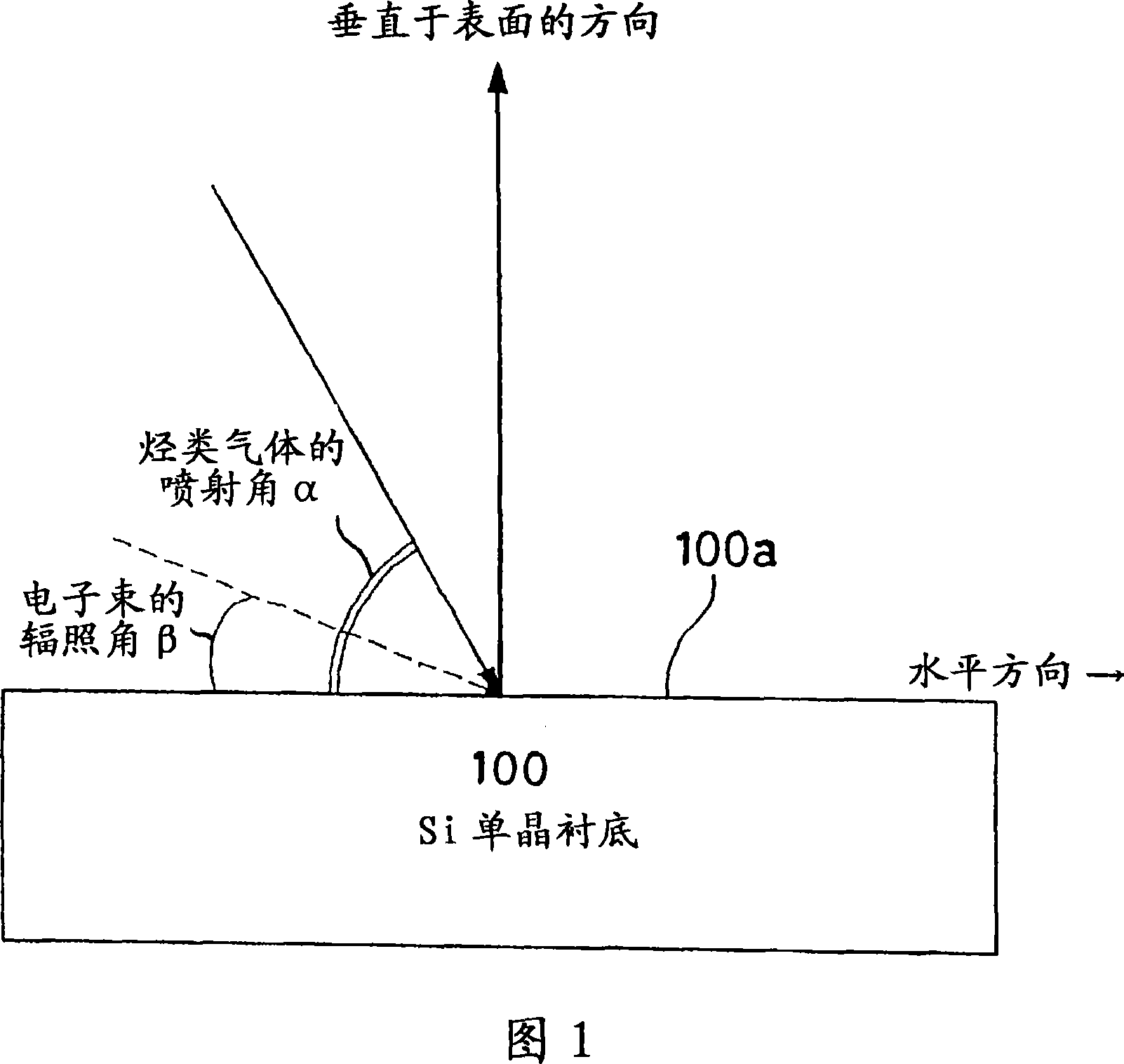

[0022] Advantageously used to form layers of cubic silicon carbide crystals on the surface of silicon substrates are gaseous hydrocarbons that decompose at low temperatures to produce carbon-containing fragments, such as acetylene (C 2 h 2 ). Aliphatic hydrocarbon gas, which can be easily decomposed, is supplied to the MEM device kept in a high vacuum through a flow rate control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com