Silicon carbide nanometer line accompanied with string structure and preparation method thereof

A silicon carbide nanowire, silicon carbide technology, applied in chemical instruments and methods, single crystal growth, polycrystalline material growth and other directions, can solve the problems of difficult to control product structure and morphology, complex preparation process, high cost, and achieve the goal of preparation The effect of short cycle, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

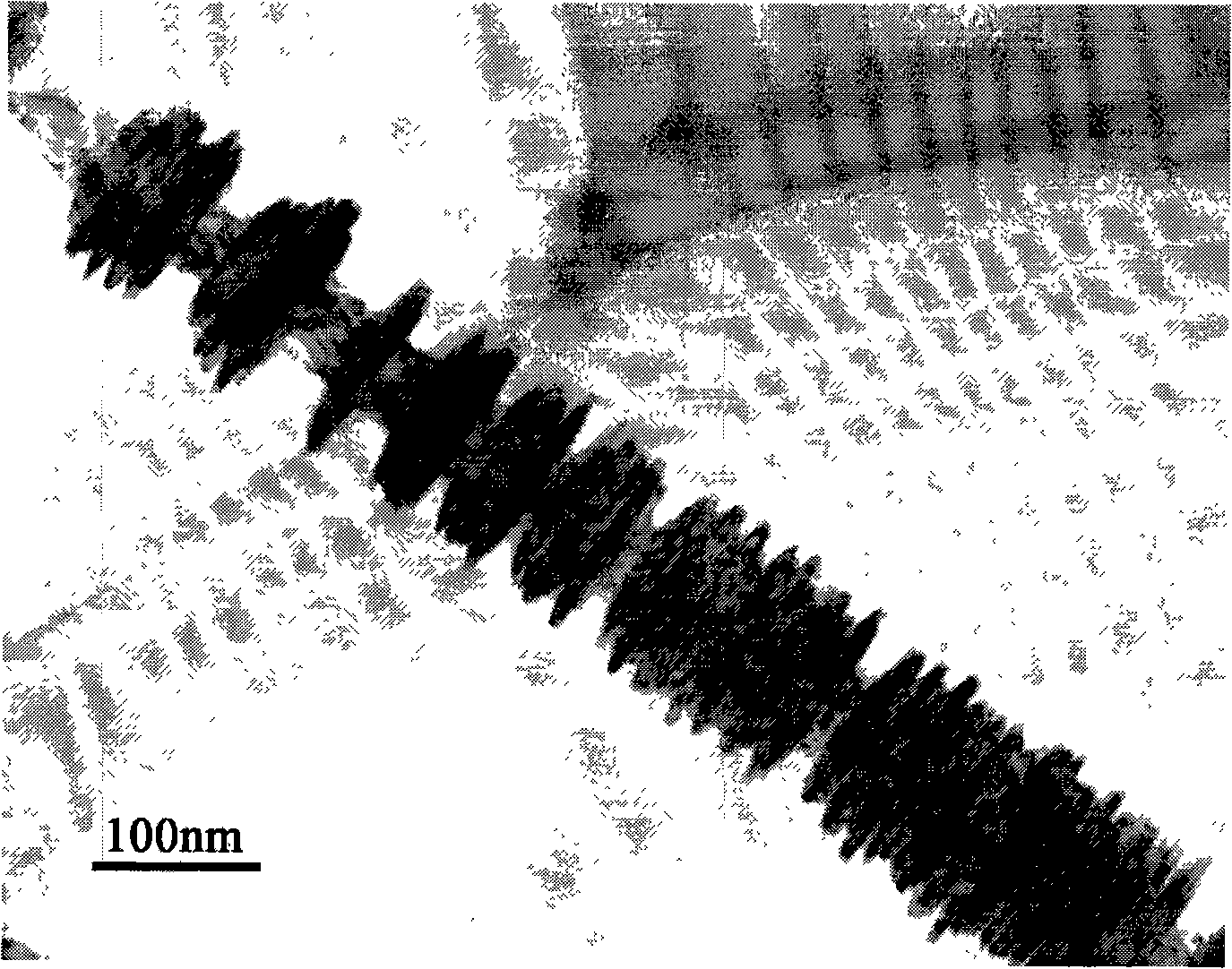

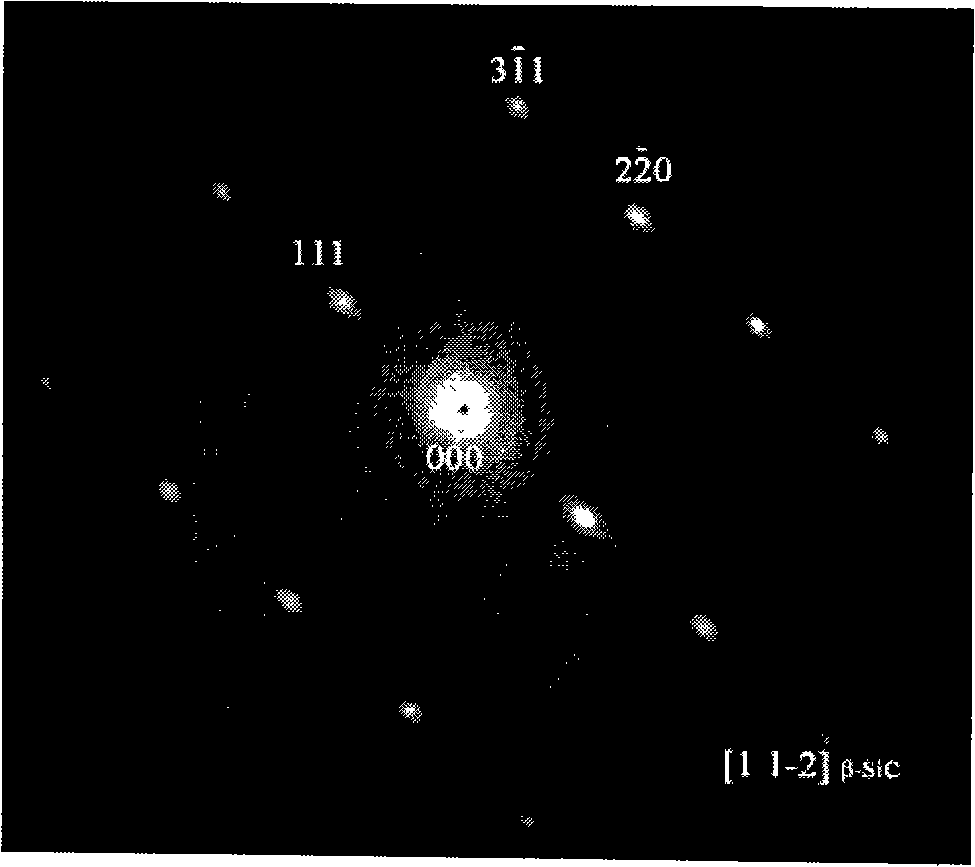

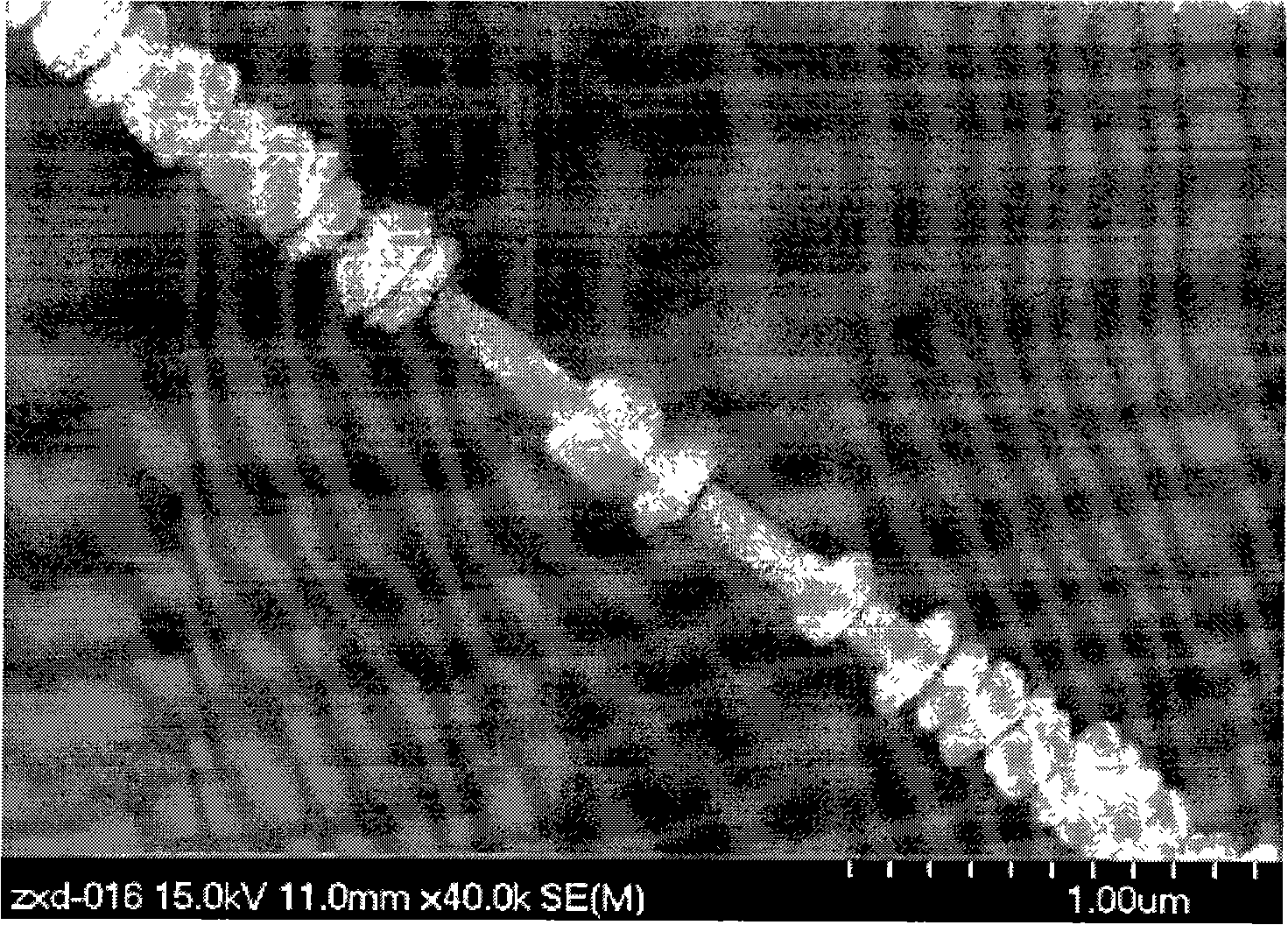

[0008] Specific Embodiment 1: The silicon carbide nanowires with a string structure in this embodiment have a single crystal structure of cubic silicon carbide, the diameter of the central rod is 50-100 nanometers, and the outer ring of the central rod has a string structure. Silicon carbide, the diameter of silicon carbide with a string structure is 100-500 nanometers, and the longest silicon carbide nanowire with a string structure can reach 4 mm, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 .

specific Embodiment approach 2

[0009] Specific embodiment two: The silicon carbide nanowires with a string structure in this embodiment are prepared through the following steps: 1. Prepare a mixed sol of silica sol and sucrose according to the molar ratio of silicon to carbon of 1:2-5, 2. Use a magnetic stirrer to stir for 2 to 4 hours at a room temperature of 15-30°C to prepare a uniform sol; 3. Put the beaker containing the sol into a water bath heater and control the temperature at 90-100°C Carry out gel treatment for 5±0.1 hours to obtain a white or slightly light yellow transparent gel; 4. Put the gel obtained in step 3 into a crucible and place it in a tubular heating furnace at a rate of 950-1100ml / min The flow rate of nitrogen gas is passed into the tube heating furnace, and the tube heating furnace is heated to 750 ~ 850 ° C at a heating rate of 8 ~ 12 ° C / min, and the temperature is maintained for 1 hour, and then naturally cooled to room temperature under the protection of nitrogen gas, to obtai...

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 2 is that in step 1, a mixed sol of silica sol and sucrose is prepared according to the molar ratio of silicon to carbon of 1:3. Other steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com